Multi-segment insulation fix bed reactor

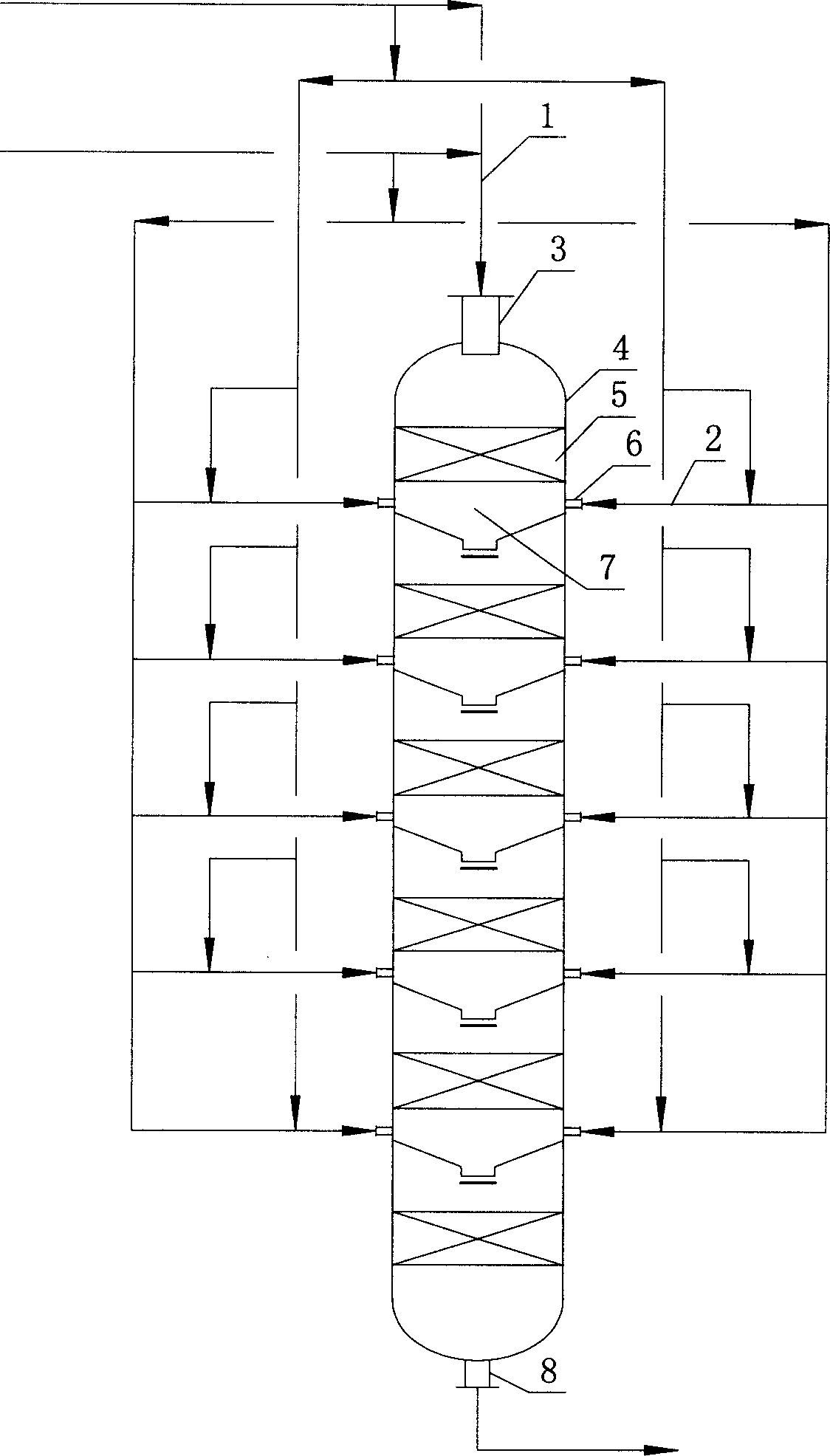

An adiabatic fixed bed and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as uneven distribution, affecting catalyst utilization, selectivity and conversion rate, and uneven mixing of two materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

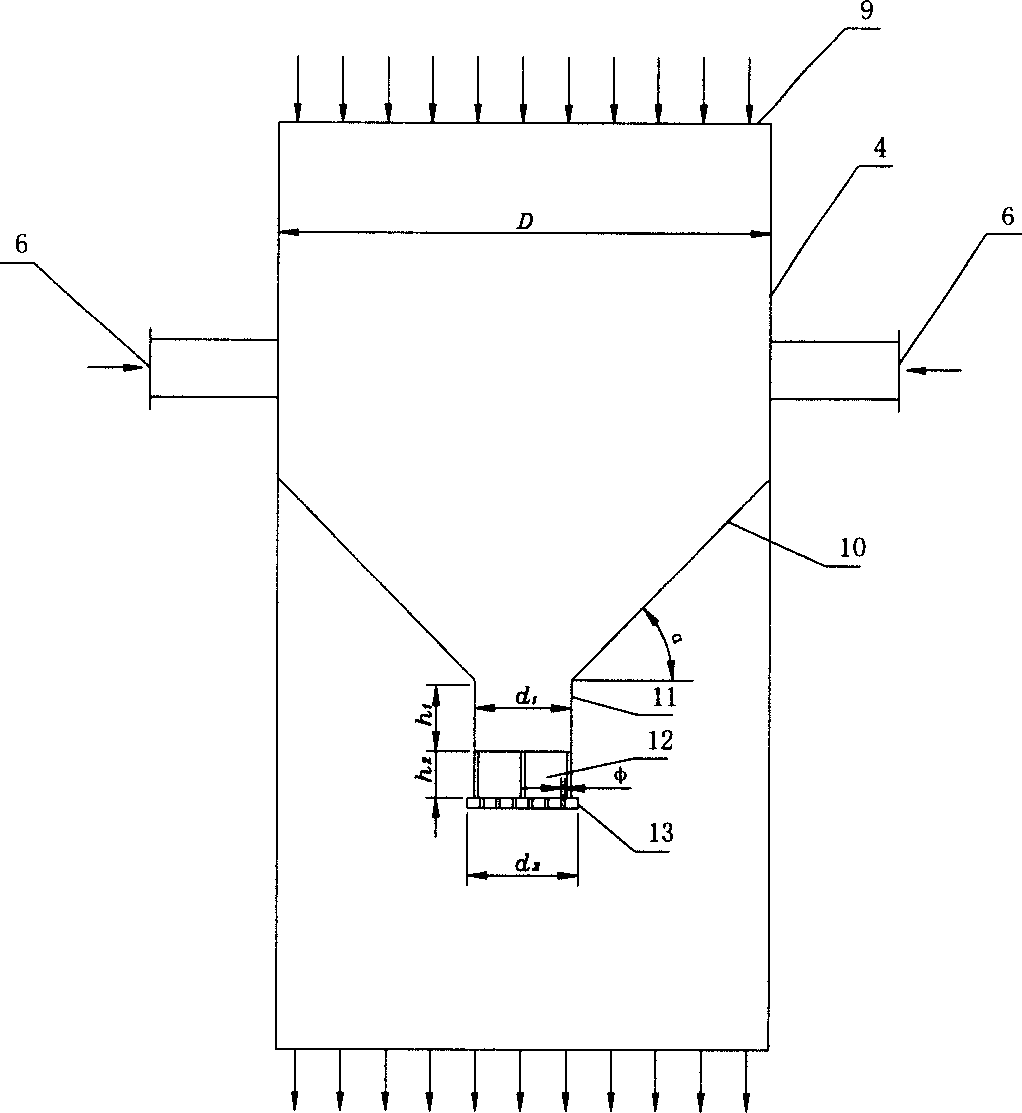

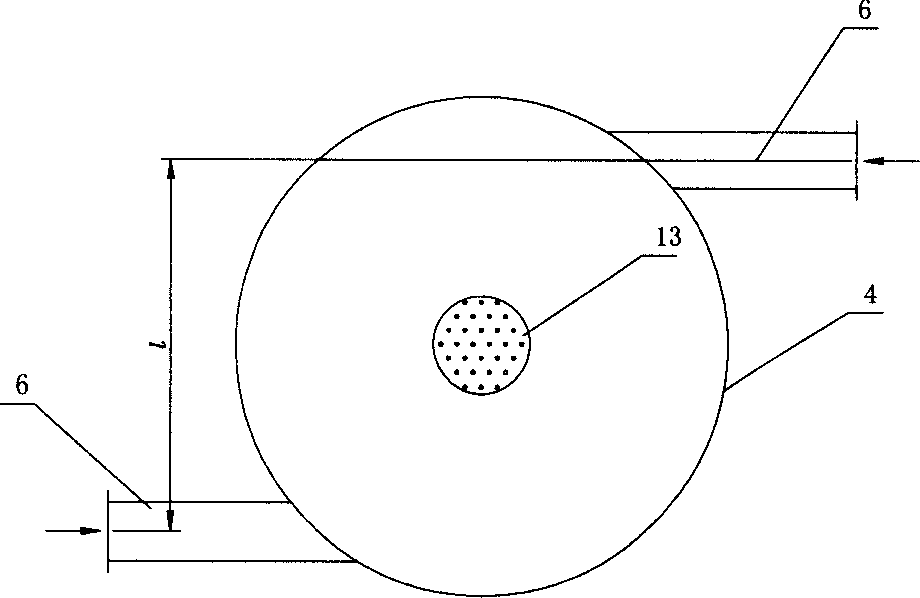

[0020] use as figure 1 The inter-stage gas mixing device shown, the diameter of the reactor D = 600 mm, the diameter of the straight pipe d 1 = 140 mm, the diameter of the sieve plate d 2 = 160 mm, the diameter of the sieve hole on the sieve plate Φ = 6 mm, the height of the straight pipe h 1 = 100 mm, the height h of the lateral annulus channel 2 =65 millimeters, the vertical or horizontal distance 1=450 millimeters of two second kinds of material inlet pipes, the angle α=45 ° of conical body and horizontal position, the vertical or horizontal distance of two second kinds of material inlets and reactor diameter The ratio of the diameter of the straight pipe to the diameter of the reactor is 75%, the ratio of the diameter of the straight pipe to the diameter of the reactor is 23.3%, the ratio of the diameter of the sieve plate to the diameter of the reactor is 26.7%, and the ratio of the opening area of the sieve plate to the area of the lateral annulus is 18.5%. , The ...

Embodiment 2

[0023] use as figure 1 The inter-stage gas mixing device shown, the diameter of the reactor D = 1000 mm, the diameter of the straight pipe d 1 = 168 mm, the diameter of the sieve plate d 2 = 168 mm, the diameter of the sieve hole on the sieve plate Φ = 8 mm, the height of the straight pipe h 1 = 160 mm, the height h of the lateral annulus channel 2 =75 millimeters, the vertical or horizontal distance 1=850 millimeters of two second kinds of material inlet pipes, the angle α=60 ° of conical body and horizontal position, the vertical or horizontal distance of two second kinds of material inlets and reactor diameter The ratio of the diameter of the straight tube to the diameter of the reactor is 85%, the ratio of the diameter of the straight pipe to the diameter of the reactor is 16.8%, the ratio of the diameter of the sieve plate to the diameter of the reactor is 16.8%, and the ratio of the opening area of the sieve plate to the area of the lateral annulus is 25.3%. , The...

Embodiment 3

[0026] use as figure 1 The inter-stage gas mixing device shown, the diameter of the reactor D = 600 mm, the diameter of the straight pipe d 1 = 165 mm, the diameter of the sieve plate d 2 = 165 mm, the diameter of the sieve hole on the sieve plate Φ = 6 mm, the height of the straight pipe h 1 = 120 mm, the height h of the lateral annulus channel 2 =60 millimeters, the vertical or horizontal distance 1=420 millimeters of two second kinds of material inlet pipes, the angle α=30 ° of conical body and horizontal position, the vertical or horizontal distance of two second kinds of material inlets and reactor diameter The ratio of the diameter of the straight pipe to the diameter of the reactor is 70%, the ratio of the diameter of the straight pipe to the diameter of the reactor is 27.5%, the ratio of the diameter of the sieve plate to the diameter of the reactor is 27.5%, and the ratio of the opening area of the sieve plate to the area of the lateral annulus is 12.6%. , The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com