Point light source light-emitting diode structure and producing method thereof

A technology of light-emitting diodes and point light sources, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve the problems of low optical coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a point light source light emitting diode element structure and a manufacturing method thereof, which are suitable for optical fiber communication elements, and have the technical advantages of high brightness, strong light coupling efficiency, and simple manufacturing process. It can concentrate the emitted light without using a complicated manufacturing process to achieve expectations. Shaped point light source.

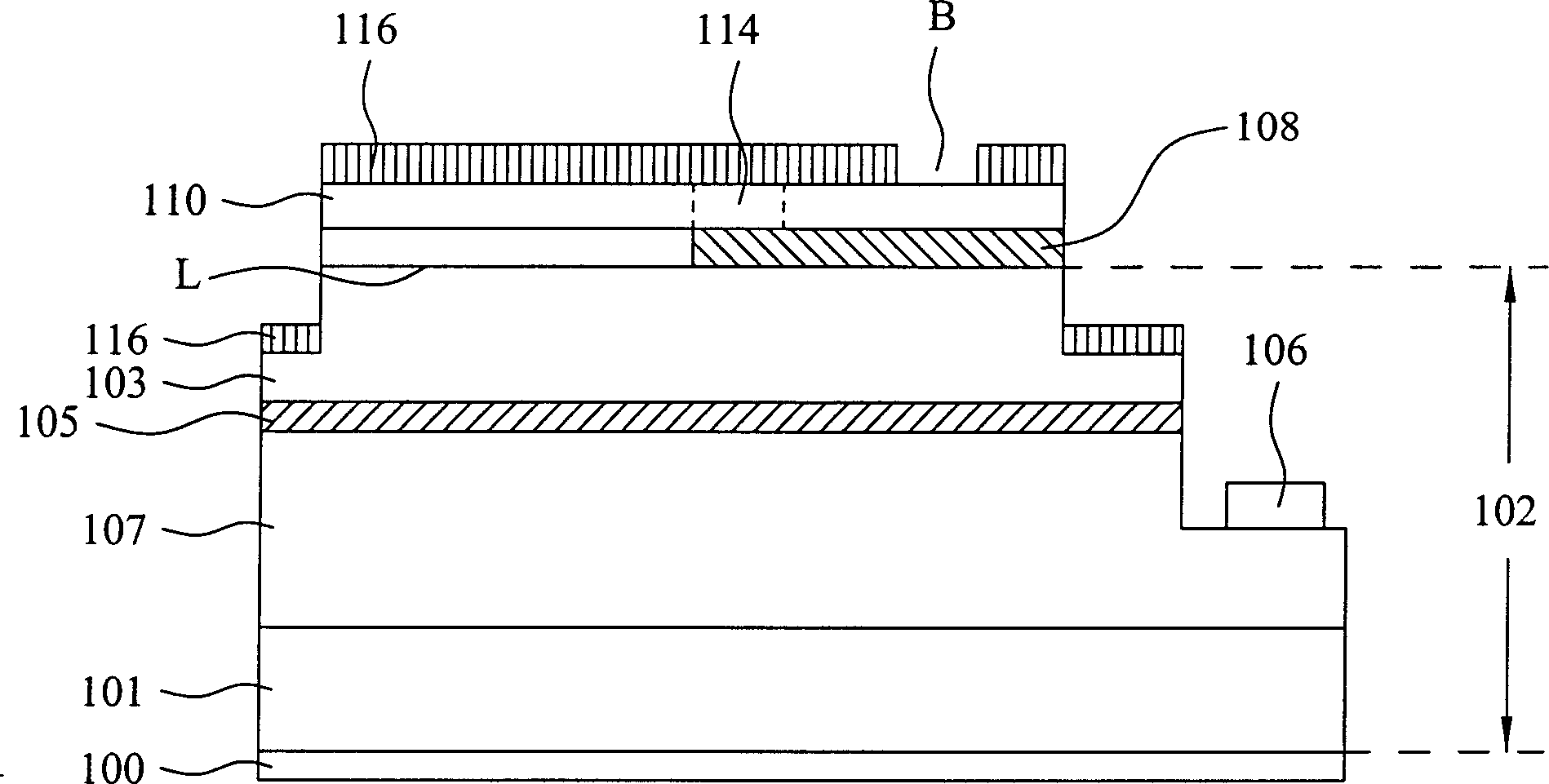

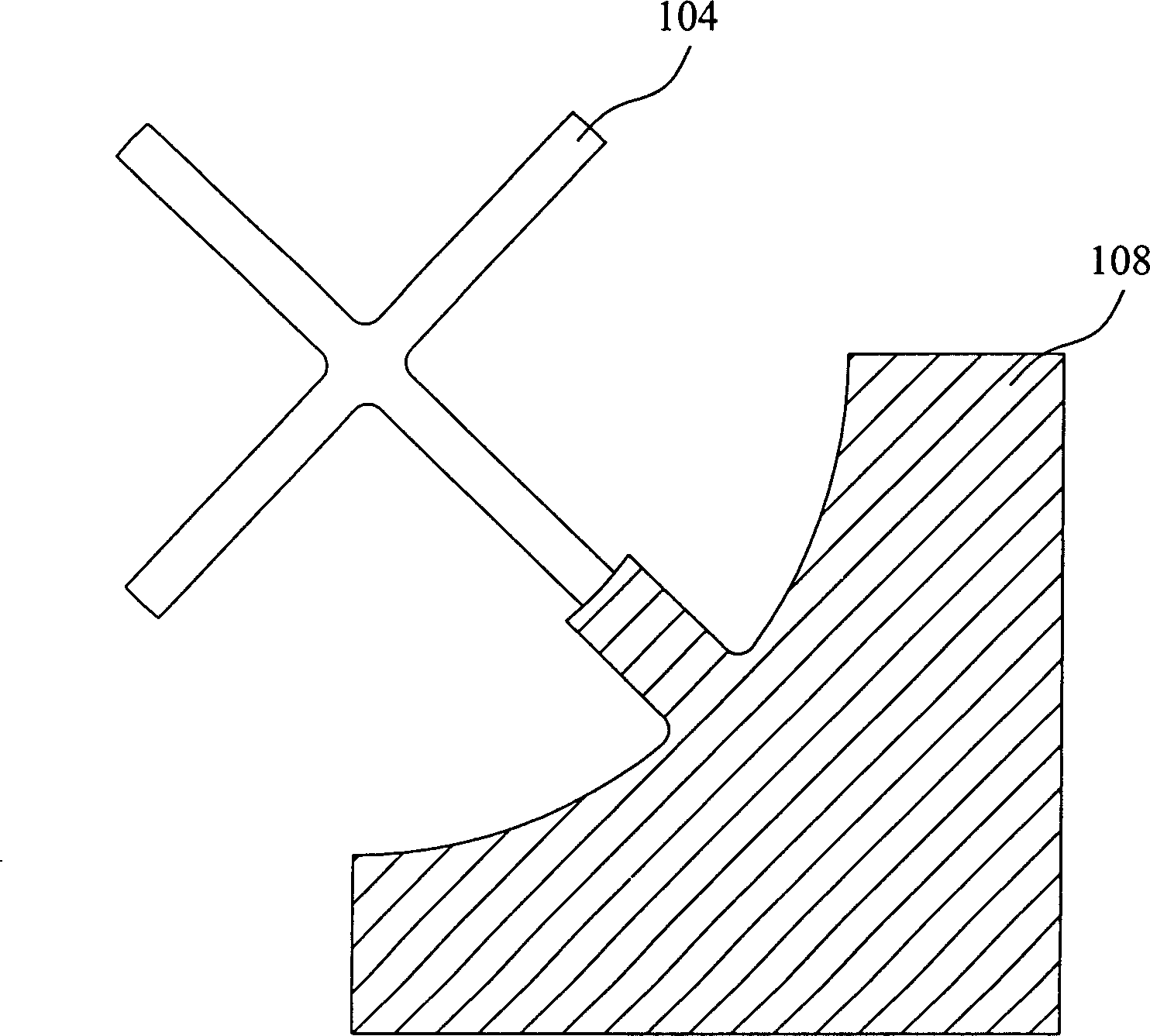

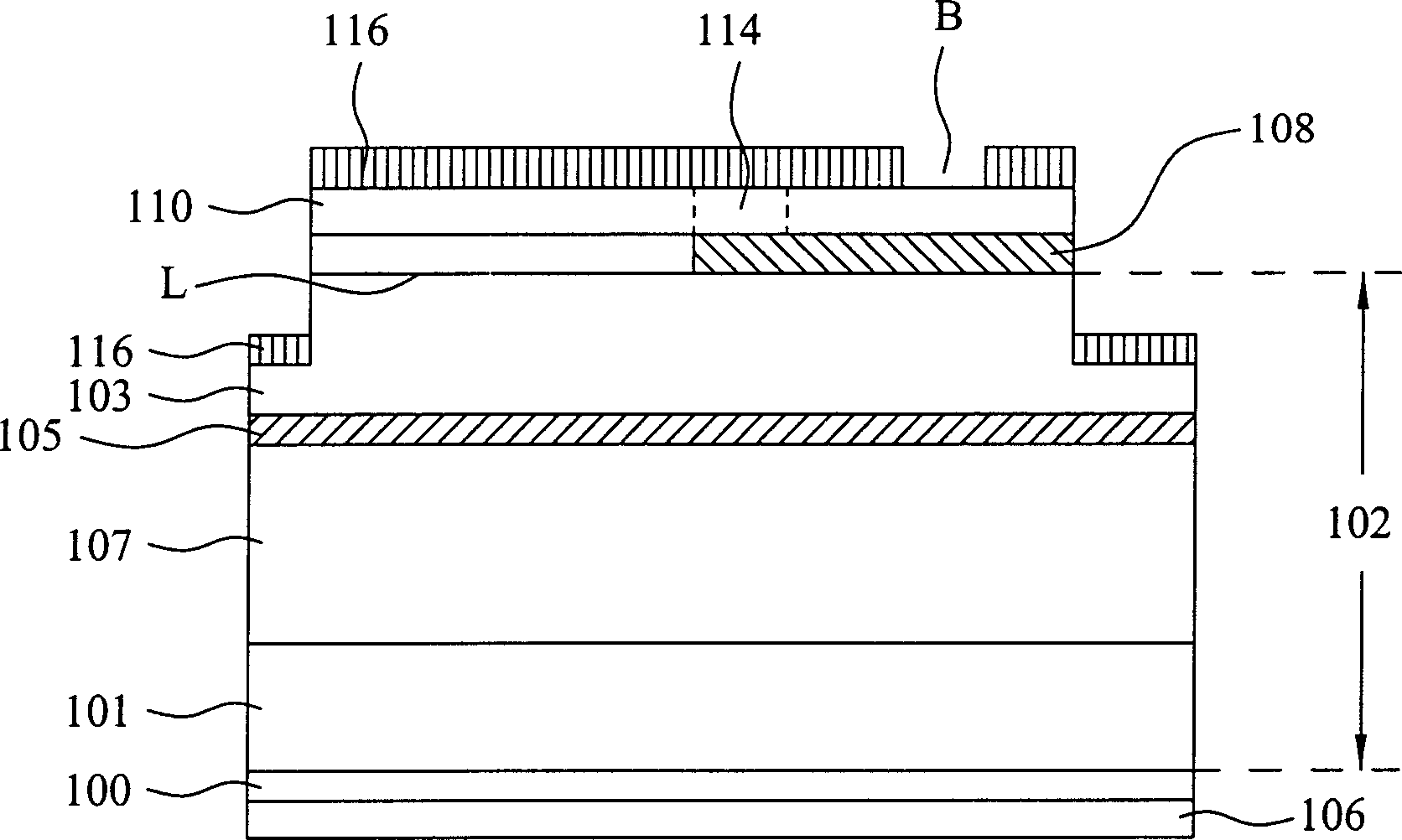

[0021] The embodiment of the present invention provides a point light source light emitting diode element structure of an optical fiber communication element. The point light source light emitting diode element structure at least includes: a substrate, an epitaxial structure, a first electrode layer and a second electrode layer, an insulating layer, and a contact Layers, connecting bridges and wiring layers.

[0022] Please refer to Figure 1a , Figure 1a It is a schematic cross-sectional view of a point light source LED according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com