Two-stage lifting superhigh voltage hot-line cleaning robot

A live cleaning and lifting technology, applied in the field of robots, can solve the problems such as the inability to adjust the insulation relationship of the lifting height of the whole machine, increase the difficulty of design and manufacture of insulating oil cylinders, increase the difficulty and cost of design and manufacture, and achieve light weight and simple structure. , the effect of reducing weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

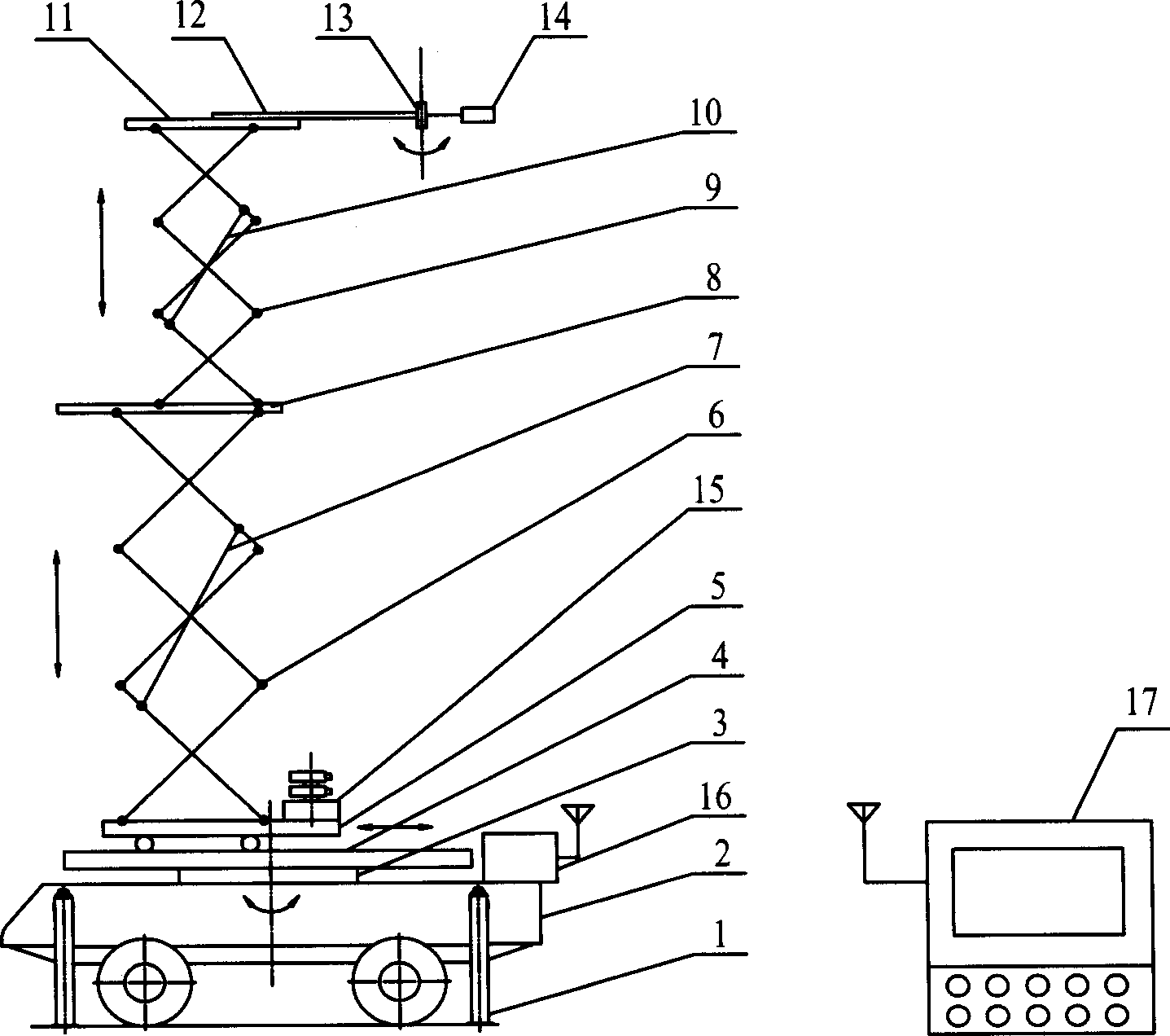

[0009] like figure 1 As shown, the present invention includes: a hydraulic automatic leveling system 1, a mobile vehicle 2, a slewing platform 3, a lifting mechanism horizontal moving track 4, a fork moving platform 5, a lower fork frame 6, a lower lifting cylinder 7, and a fork frame connecting platform 8. Superior fork frame 9, superior insulating lifting cylinder 10, insulating platform 11, cleaning arm 12, claw movable joint 13, cleaning claw 14, cloud platform 15, central control system 16, remote operation terminal 17. The connection relationship is: the cleaning claw 14 is connected to the cleaning arm 12 through the claw movable joint 13, the cleaning arm 12 and the insulating platform 11 are directly fixed on the upper-level fork frame 9, and the upper-level fork frame 9 and the lower-level fork frame 6 are connected through the fork frame The platform 8 is fixed together, and the upper and lower fork frames 9 and 6 realize the vertical lifting movement through the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com