Multilayer printed wiring board-use copper-clad laminate sheet, multilayer printed wiring board and production method for multilayer printed wiring board

A multi-layer printing and wiring board technology, applied in printed circuit manufacturing, multi-layer circuit manufacturing, printed circuit, etc., can solve the misalignment of inner layer circuit, unevenness of single-sided circuit substrate, film thickness or stickiness of adhesive layer Differences and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

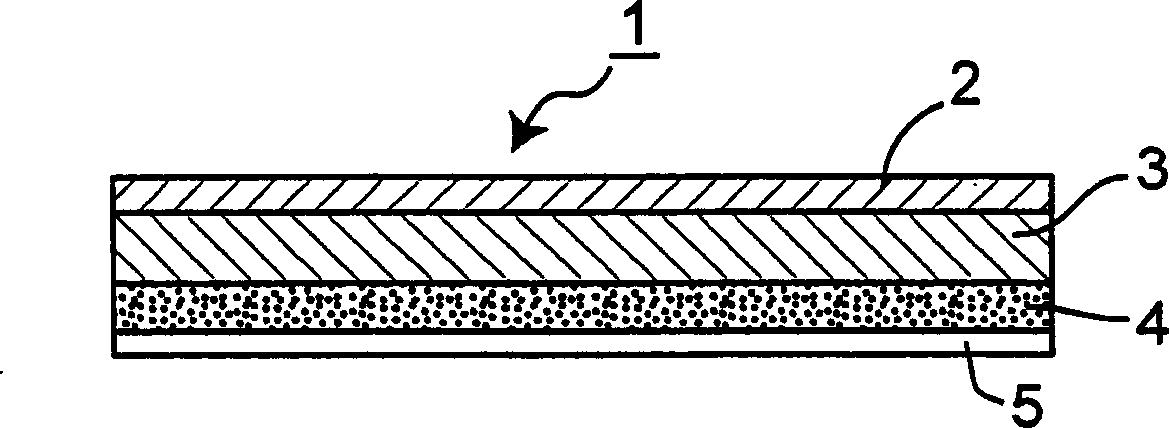

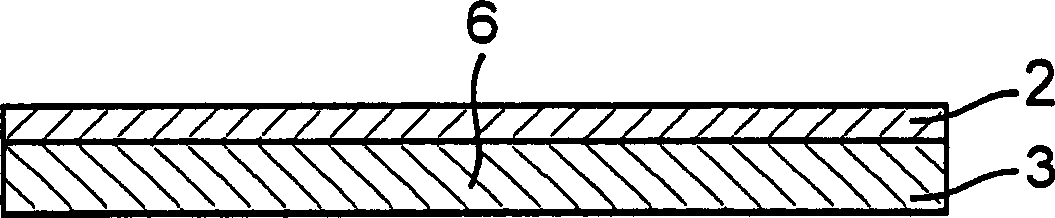

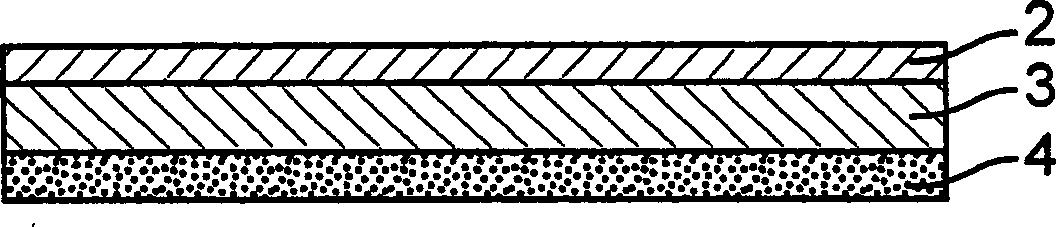

[0076] As such Figure 2A The single-sided circuit board 6 shown uses FR-4 grade glass fabric base epoxy resin single-sided copper foil laminated board (manufactured by Matsushita Electric Works, product number R-1661, with a thickness of 0.1mm in hard insulating layer, The thickness of the copper foil is 18μm). Secondly, such as Figure 2B As shown, an epoxy resin adhesive is applied to the surface of the hard insulating layer 3 with a thickness of 30 μm by roll coating, and heated (60° C.) until there is no tuck property to form the adhesive layer 4. Next, using a laminator (temperature 80°C, pressure 0.05MPa), the protective film 5, namely, a polyethylene terephthalate film (manufactured by Toray Corporation, product number T-60, thickness 38μm) was laminated on the adhesive The surface of the adhesive layer 4, such as Figure 2C As shown, a copper foil laminated board 1 for a multilayer printed wiring board is manufactured.

[0077] Next, a photosensitive dry film is laminated...

Embodiment 2

[0083] Same as in Example 1, manufactured as Figure 5 The single-sided circuit boards 11a, 11b, 11c, and 11d are shown. Secondly, the upper and lower surfaces of the core substrate 13 that are connected between the inner circuits formed on both sides, such as Figure 5 As shown, the single-sided circuit boards 11a, 11b and the single-sided circuit boards 11c, 11d are respectively arranged, and pseudo-fixed and aligned in position by the pin lamination method. The single-sided circuit boards 11a, 11b, 11c, and 11d are flat surfaces on which no warpage or distortion occurs. Therefore, the position can be easily aligned.

[0084] In this way, after overlapping and aligning the core substrates 13 and the single-sided circuit substrates 11a, 11b, 11c, and 11d, they are heated and pressurized (180°C, 1 hour) under vacuum using hot pressing to obtain Figure 6 The multilayer printed wiring board 12 is shown. The obtained multilayer printed wiring board 12 did not cause misalignment in t...

Embodiment 3

[0086] Same as in Example 1, manufactured as Figure 7 Single-sided circuit boards 11b and 11c are shown. In addition, such as Figure 7 As shown, the conductive bumps 10 are formed, and the surface layer substrate 14a with no circuit formed on the copper-clad foil 2 was manufactured under the conditions for manufacturing the single-sided circuit board 11a in Example 1. Similarly, another surface layer substrate 14b was manufactured.

[0087] Secondly, such as Figure 7 As shown, the surface layer substrate 14a, the single-sided circuit substrates 11b, 11c, and the other layer substrates 14b are superimposed and aligned, and the positions are pseudo-fixed by the lamination method. The surface-layer substrates 14a, 14b, and the single-sided circuit boards 11b, 11c are flat surfaces on which no warpage or distortion occurs, and therefore, position alignment is easy.

[0088] In this way, after the surface layer substrates 14a, 14b, and the single-sided circuit substrates 11b, 11c ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com