Copper-free wires for gas-shielded arc welding

A technology of gas shielding and copper welding wire, applied in arc welding equipment, welding medium, welding equipment, etc., can solve the problems of impossible coating of functional coating agent, hindering the stable contact between contact tip and welding wire, unstable wire feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments are described in detail below with reference to the accompanying drawings.

[0017] As mentioned above, unlike the copper-coated welding wire of the conventional technology, although the copper-free welding wire must have special properties on its surface in order for the welding wire to stably contact the contact tip, so far, methods for providing special properties to it have been limited to The surface roughness, specific surface area, etc. of the wire surface are controlled within specified ranges, and stable contact between the contact tip and the wire cannot be achieved with these methods.

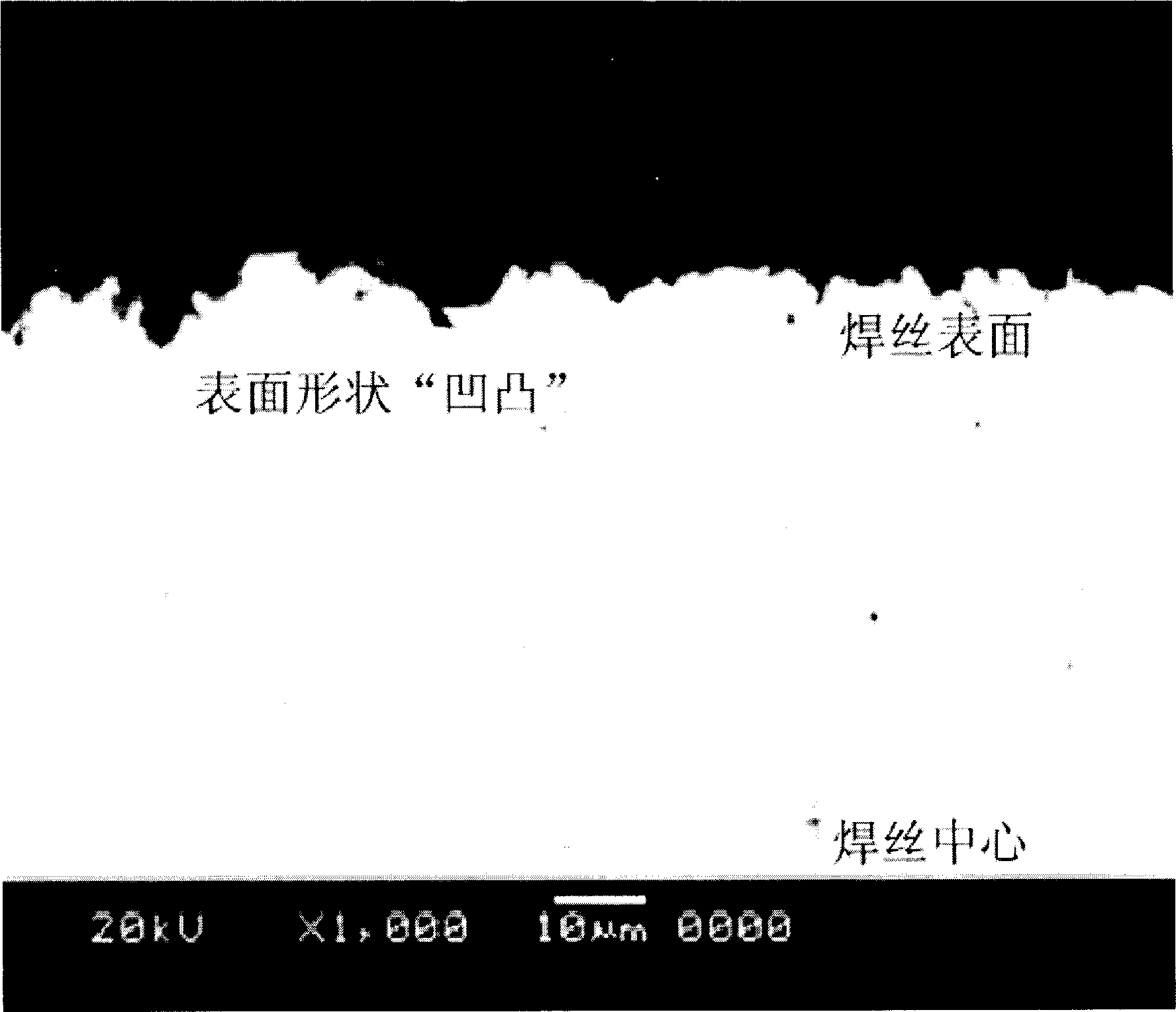

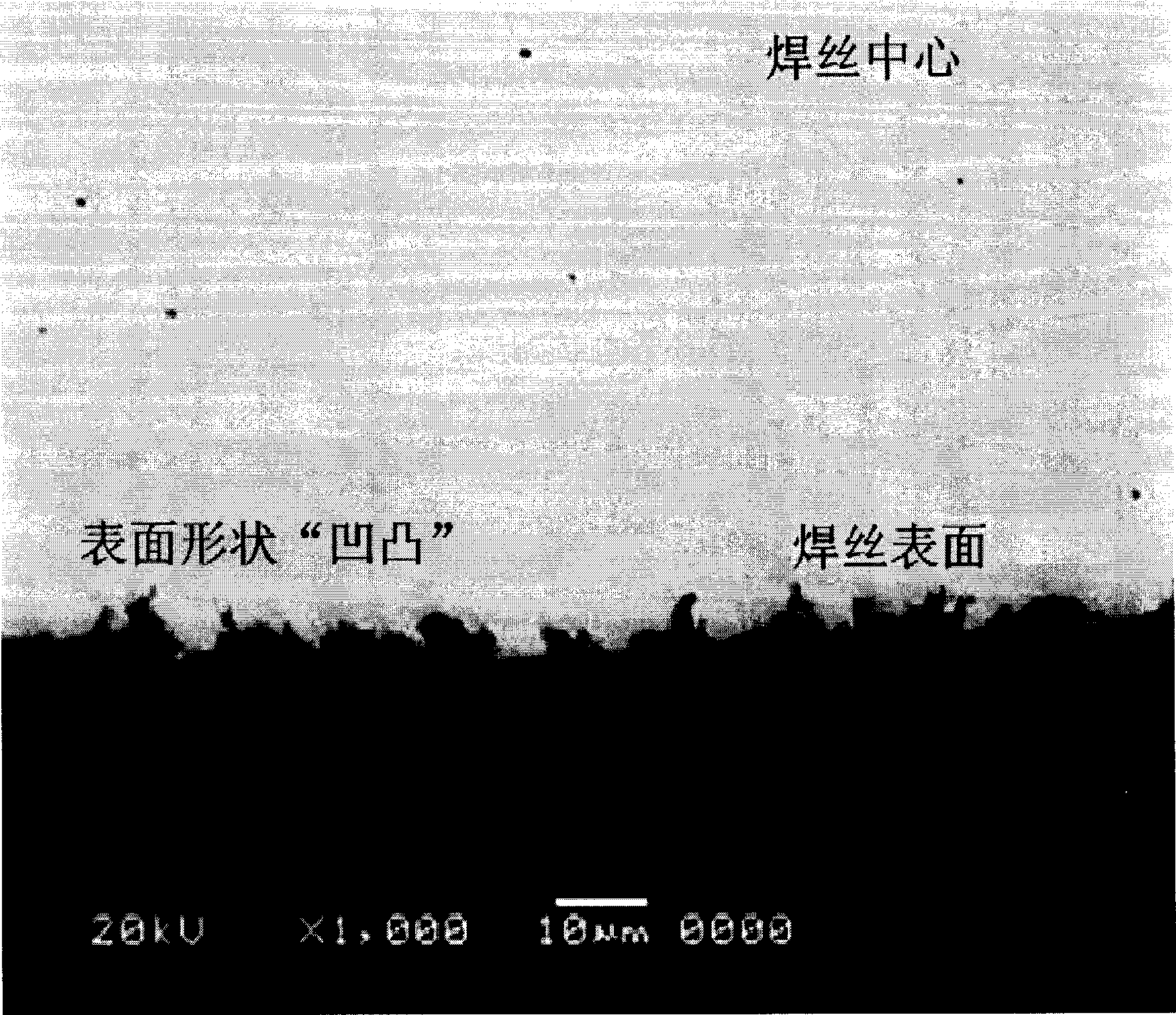

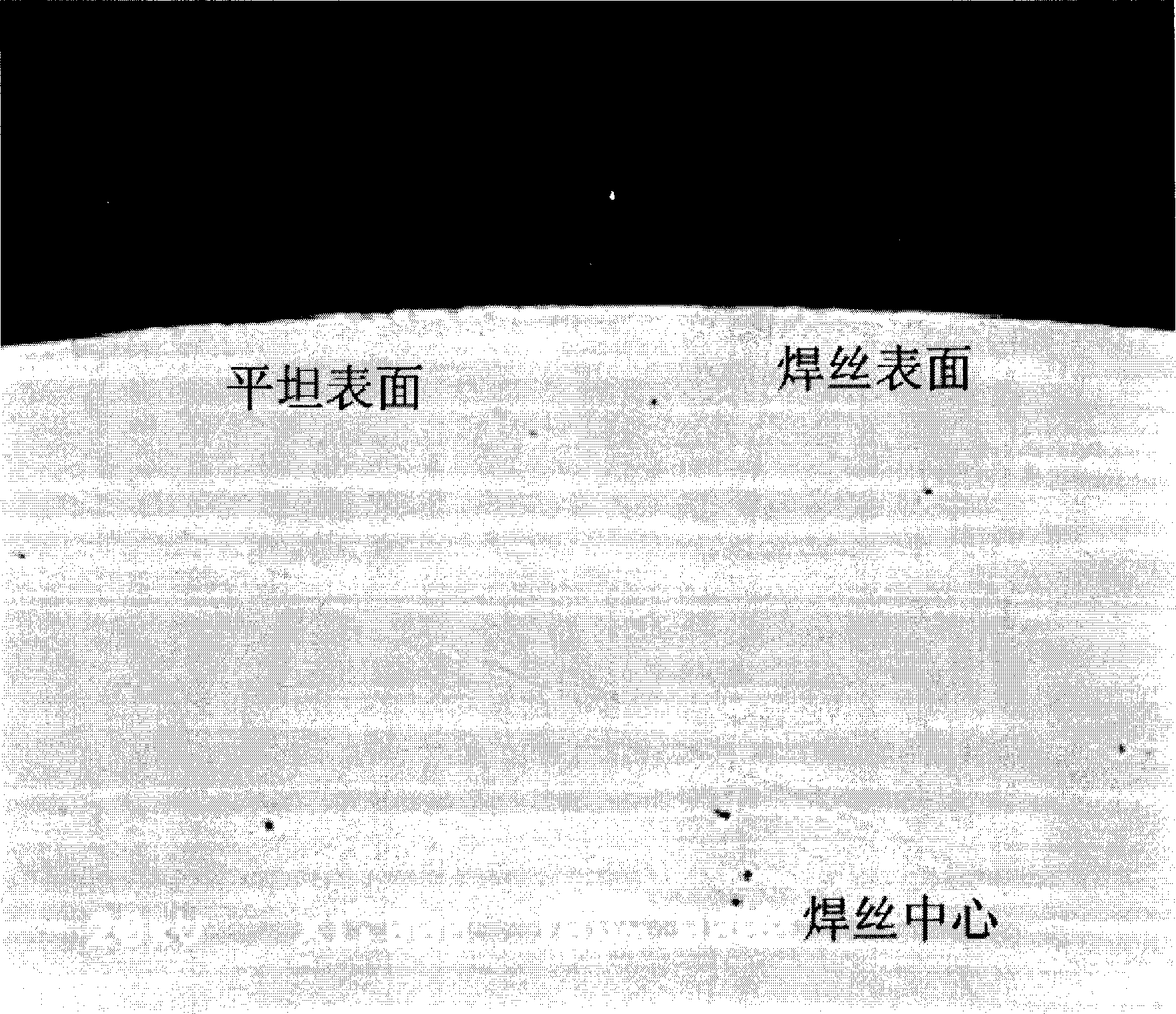

[0018] In order to replace the copper plating on the surface of the welding wire, in the continuous research of the method of providing special properties to the surface of the welding wire, the present inventors found that the surface of the welding wire can be divided into three types of surfaces, that is, flat surfaces consisting only of processed surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com