Copper-free solid welding wire and preparation method thereof

A solid welding wire, copper-free technology, applied in the direction of welding equipment, manufacturing tools, welding media, etc., can solve the problems of affecting the comprehensive performance of welding joints, affecting the health of welders, and poor weld formation, so as to improve the mechanical properties of welds, Rich in functionality and good quality of weld seam formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033]

[0034] The preparation method of copper-free solid welding wire of the present invention comprises the steps:

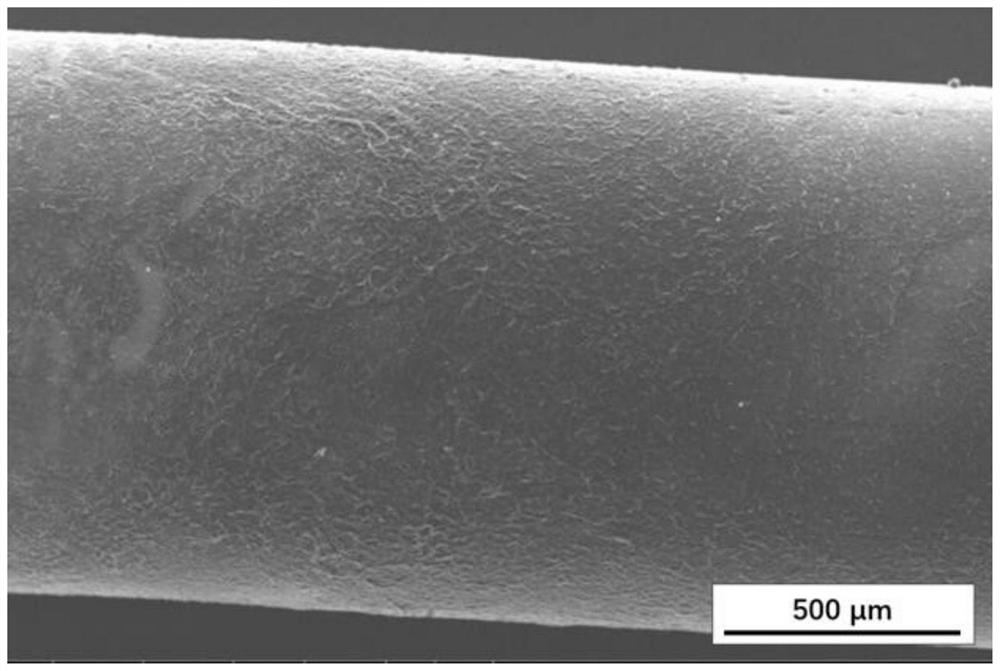

[0035] (1) After the wire is mechanically peeled and polished with an abrasive belt, it is drawn to the specified wire diameter according to the conventional method to obtain a solid welding wire;

[0036] (2) Perform high-pressure water washing, ultrasonic cleaning, initial drying, soaking, and then drying on the surface of the solid welding wire, and layer winding to obtain a copper-free solid welding wire.

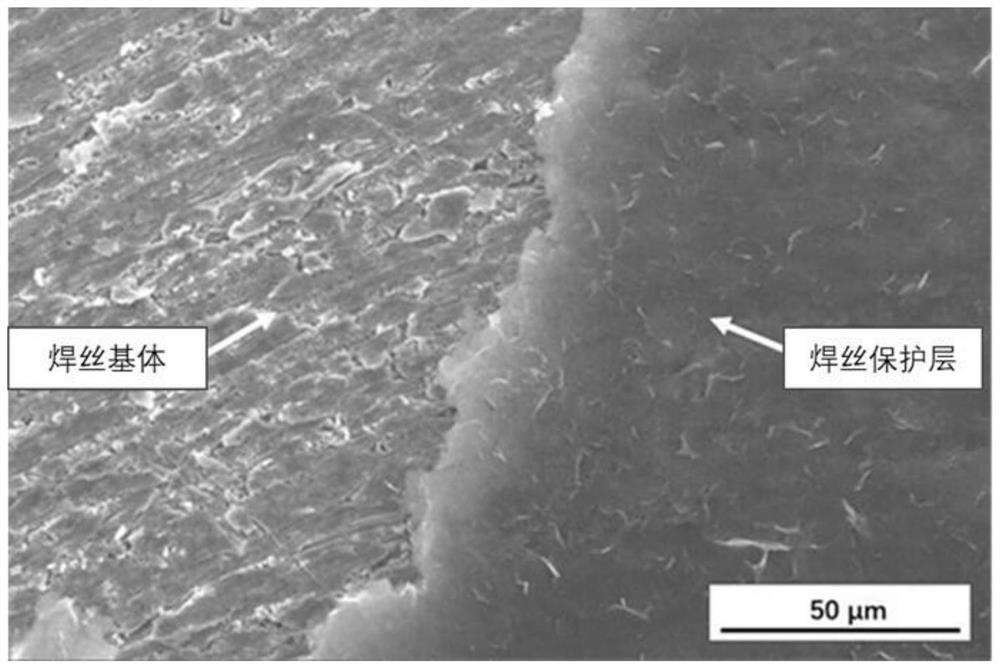

[0037] Wherein, when soaking, the soaking solution includes the following components: 2-5wt% sorbitan monooleate, 3-5wt% sodium petroleum sulfonate, 0.15-0.25wt% benzotriazole (granular or powdery), 0.5-2.5wt% lanolin magnesium soap, 0.25-0.65wt% sodium dodecylsulfonate, 0.1-0.2wt% titanium dioxide, 3-5wt% graphene and / or fullerene, 2-6wt% molybdenum disulfide (the mesh number of molybdenum disulfide ≥ 800 mesh), 0.1-0.2wt% cerium oxide, mineral he...

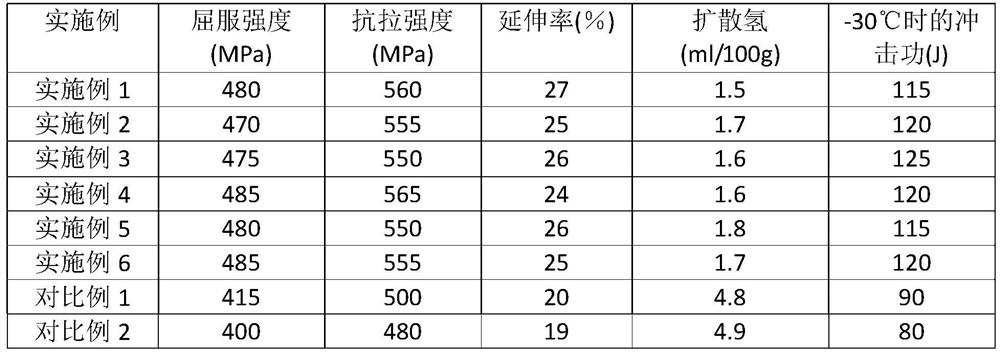

Embodiment 1

[0054] The preparation method of the copper-free solid welding wire of the present embodiment comprises the steps:

[0055] (1) After mechanical peeling and abrasive belt polishing, the wire is drawn to a solid welding wire with a diameter of 0.8 mm in a conventional manner, and the protective layer of the solid welding wire is processed.

[0056] (2) High-pressure water washing: Put the solid welding wire with a diameter of 0.8 mm into a high-pressure water washing machine for cleaning. The cleaning time is 10 seconds, and the pressure of high-pressure water is 1.5 MPa.

[0057] (3) Ultrasonic cleaning: Put the solid welding wire with a diameter of 0.8mm into the ultrasonic cleaning machine for cleaning; wherein, the ultrasonic cleaning solution is prepared with Rockaway RA-6031 cleaning agent, the temperature of ultrasonic cleaning is 42°C, and the cleaning time is 3min.

[0058] (4) Initial drying: the solid welding wire that has completed the washing process is put into t...

Embodiment 2

[0062] The preparation method of the copper-free solid welding wire of the present embodiment comprises the steps:

[0063] (1) After mechanical shelling and abrasive belt polishing, the wire is drawn to a solid welding wire with a diameter of 1.2 mm in a conventional manner, and the protective layer of the solid welding wire is processed.

[0064] (2) High-pressure water washing: Put the solid welding wire with a diameter of 1.2 mm into a high-pressure water washing machine for cleaning. The cleaning time is 5 seconds, and the pressure of high-pressure water is 2.0 MPa.

[0065] (3) Ultrasonic cleaning: Put the solid welding wire with a diameter of 1.2 mm into the ultrasonic cleaning machine for cleaning; wherein, the ultrasonic cleaning solution is prepared with Rockaway RA-6031 cleaning agent, the temperature of ultrasonic cleaning is 47 ° C, and the cleaning time is 4min.

[0066] (4) Initial drying: the solid welding wire that has completed the water washing process ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com