Anti-pollution fiber structure and its processing method

A technology of fiber structure and processing agent, applied in the field of anti-fouling fiber structures, it can solve the problems of yellowing, odor, yellowing, etc., and achieve the effect of preventing soaking, good absorption, and good feeling comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

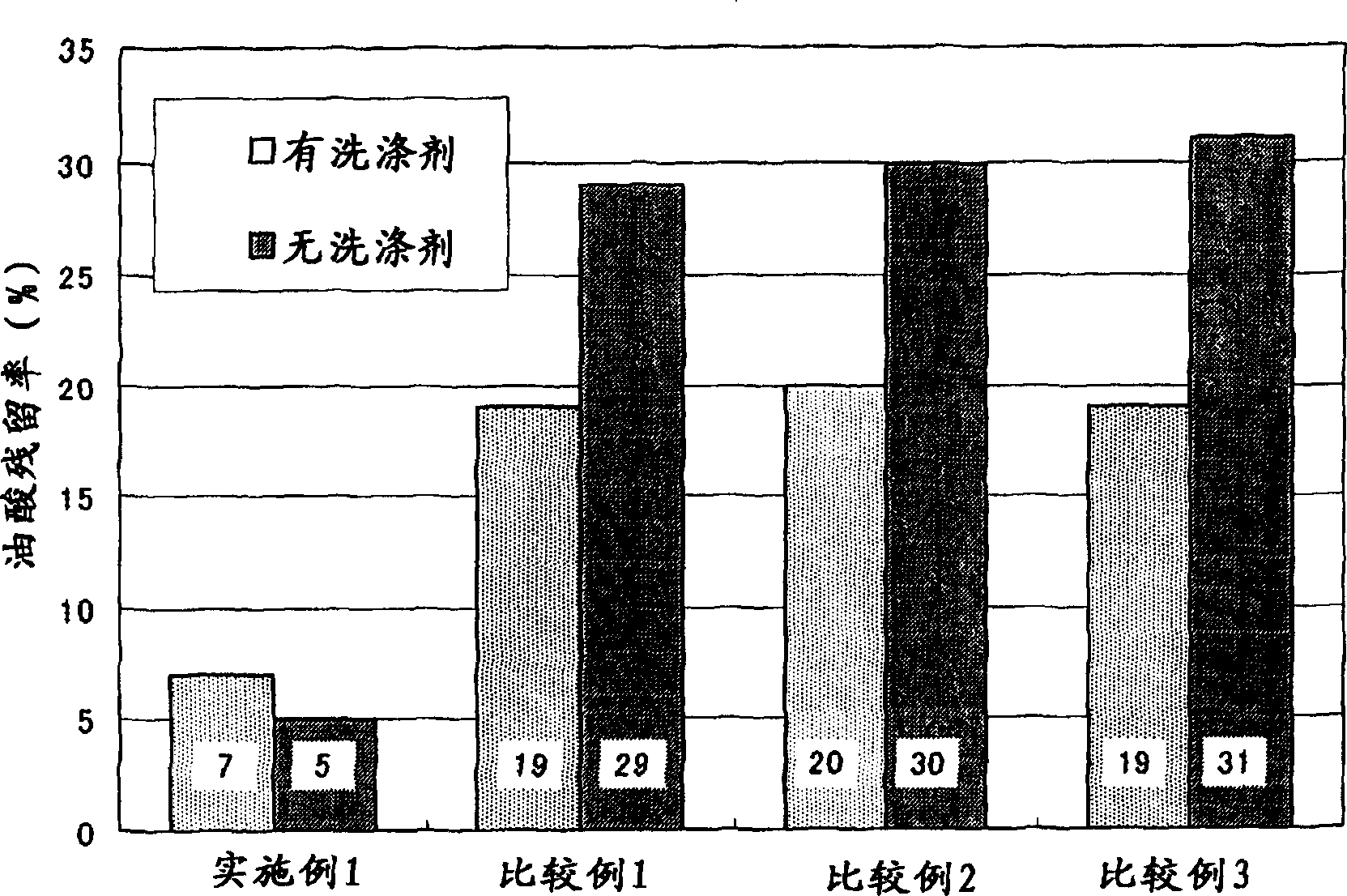

Examples

Embodiment 1

[0055] The gray cloth of cotton / polyester blended wide width (warp 50 count × weft count 50 count / entering warp 142 × weft 76) is desized, scoured, bleached, and mercerized by the usual method. Immerse the gray cloth in the following formula In the treatment solution, the padding treatment was carried out with a 70% scrap rate, dried at 120°C for 1 minute, and then baked at 160°C for 2 minutes to make the treatment solution adhere to the gray cloth.

[0056] (Anti-wrinkle + Hydrophilic, oil-repellent and anti-fouling processing agent treatment liquid formula)

[0057] Ingredients Mixing Ratio

[0058] パラレヂ NC-3 (manufactured by Ohara Paraヂウム Chemical Co., Ltd.) 5% by mass

[0059] ベツカミン LF-55Pconque (manufactured by Dainippon Ink Chemicals Co., Ltd.) 15% by mass

[0060] Catalyst GT-3 (manufactured by Dainippon Ink Chemicals Co., Ltd.) 3% by mass

[0061] Softtex N-491 (manufactured by Kitahiro Chemical Co., Ltd.) 1% by mass

[0062] パ-Marin MR 100 (manufactured by Sanyo C...

Embodiment 2

[0119] 100% cotton wide-width (warp 50 count x weft count 40 count / punched warp 148 x weft 70) gray cloth is subjected to reaction dyeing after desizing, scouring, bleaching, and mercerizing by the usual method, and then dipping In the treatment solution with the fixative of the following formula (1), the padding treatment was carried out at a pass rate of 70%, and dried at 120° C. for 1 minute.

[0120] In addition, dip in the following formula (2) of the hydrophilic, oil-repellent and anti-fouling processing agent treatment liquid, carry out the padding treatment according to the pass rate of 70%, dry at 120°C for 1 minute, and then bake at 160°C for 2 minutes , so that the gray cloth adheres to the treatment liquid.

[0121] (1)

[0122] Ingredients Mixing Ratio

[0123] Danfits 5000 (manufactured by Nittobo) 2% by mass

[0124] (2)

[0125] Ingredients Mixing Ratio

[0126] パラレヂンNC-3 (manufactured by Ohara Paraヂウム Chemical Co., Ltd.) 5% by mass

[0127] ベツカミン LF-55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com