Membrane adsorption natural gas desulfur method

A technology for natural gas and membrane absorption, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high investment cost, large equipment, bubbling, etc., to reduce investment costs, reduce operating costs, and reduce contact area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

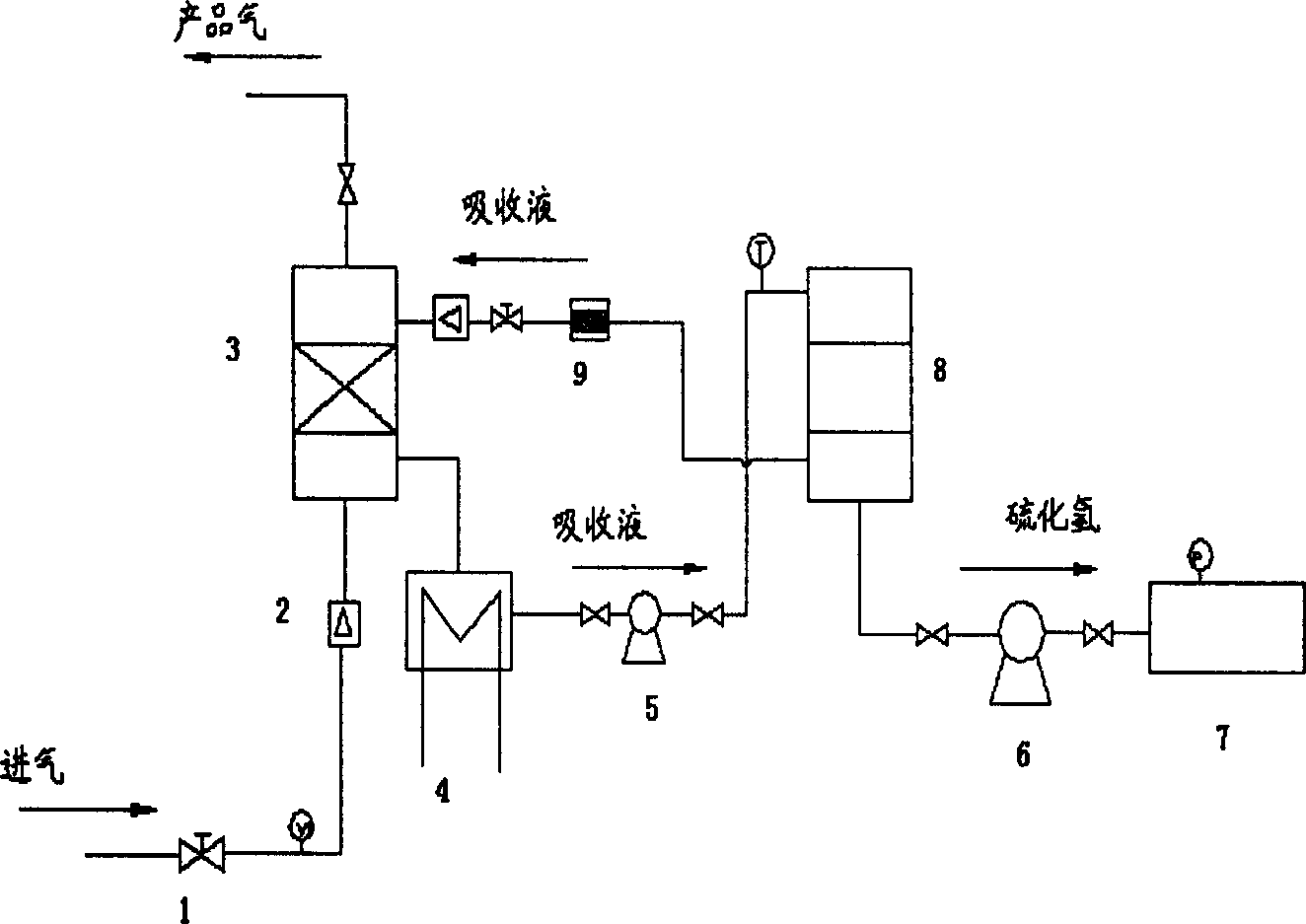

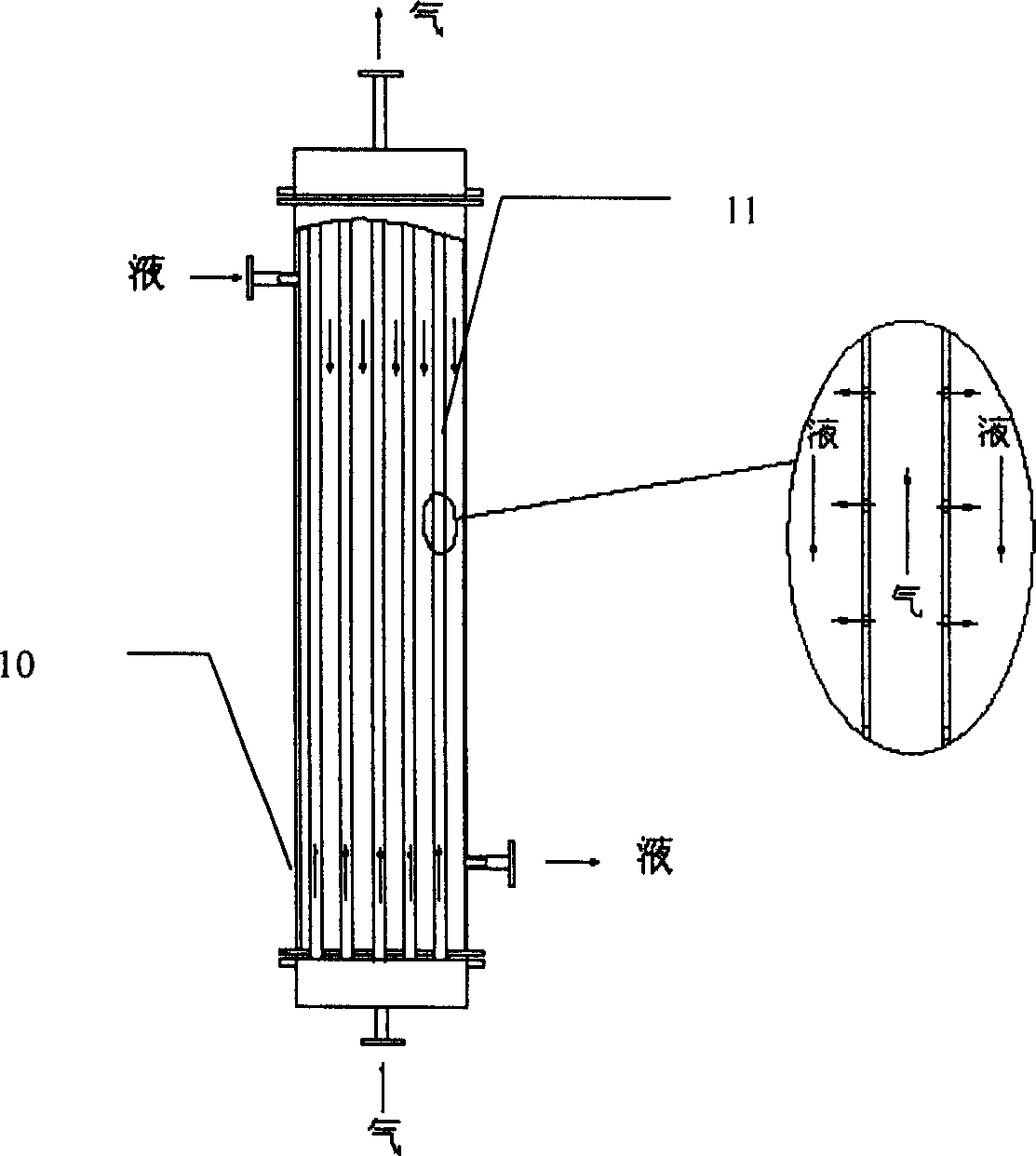

[0013] like figure 1 , 2 As shown, the raw natural gas enters the lumen of the membrane separator (3) using the microporous hollow fiber membrane tube (11) through the pressure reducing valve (1), and the hydrogen sulfide gas infiltrates into the outside of the lumen of the membrane module and is passed through The absorption liquid on the shell side of the membrane separator is carried away. The purified natural gas flows out of the membrane separator (3).

[0014] The absorption liquid passes through the filter (7) to remove impurities, enters the shell side of the membrane separator, absorbs the hydrogen sulfide gas seeping from the inside of the membrane cavity, flows out of the membrane separator (3) and enters the heat exchanger (4) is heated to a predetermined temperature, and then flows into the shell side of the membrane regenerator (8), and the hydrogen sulfide gas therein can seep into the membrane tube cavity, and is sucked away by the vacuum pump (6), and enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com