Composite packaging paper special for gravure, its production process and production equipment

A composite packaging and production equipment technology, applied in the direction of wrapping paper, wrapping paper, packaging, etc., can solve the problems of low flatness, uneven coating, high water absorption, etc., to improve product grade, simple production process, and increased flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

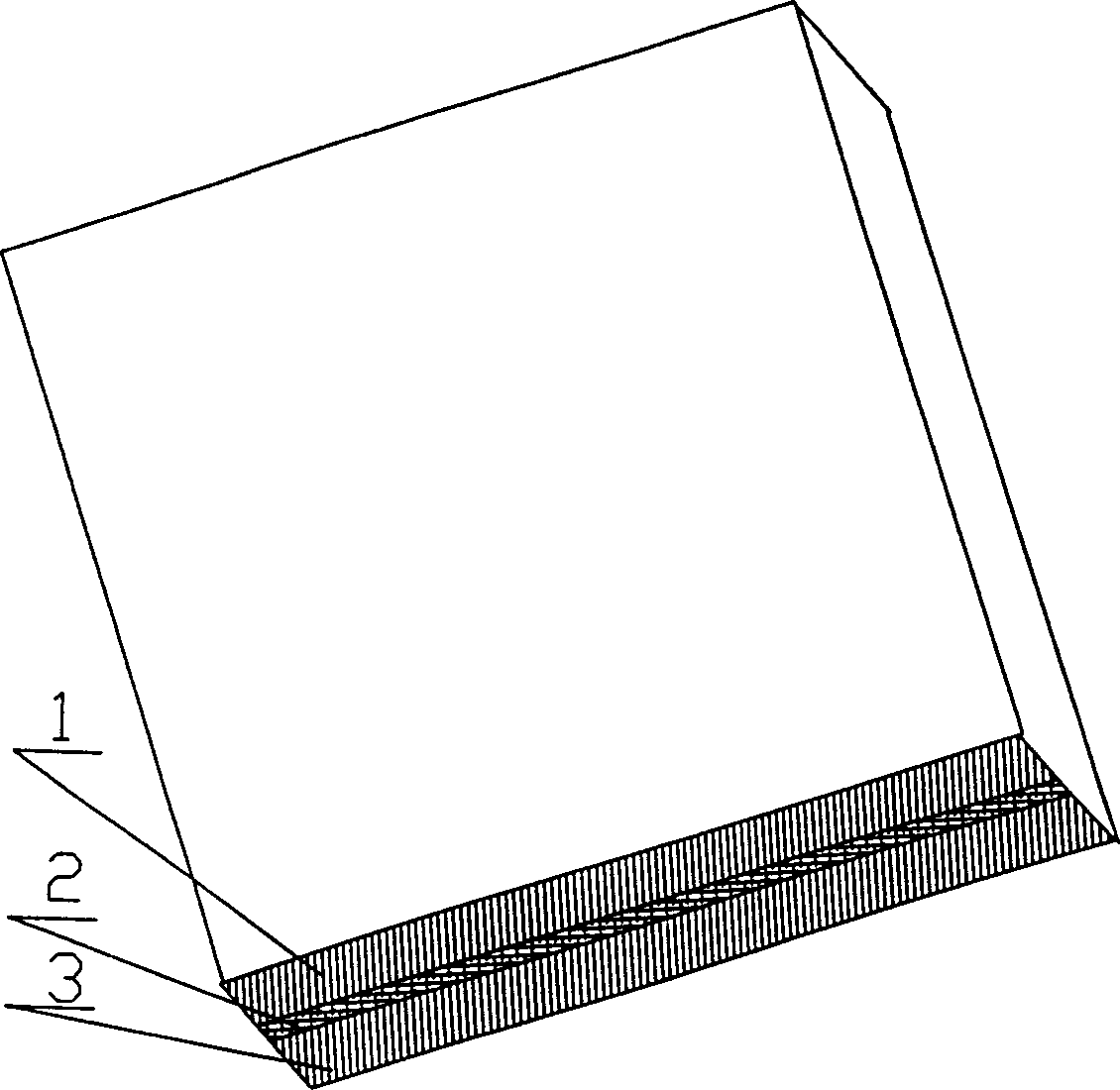

[0017] Embodiment 1, special composite wrapping paper for gravure printing, is formed by bonding the upper layer paper 1 and the lower layer lining paper 3 through the adhesive layer 2, the upper layer paper 1 is 50-100 grams of coated paper, and the lower layer lining paper 3 is 110-350 grams of gray board paper. The adhesive is latex, the dosage is 5-30g / m 2 .

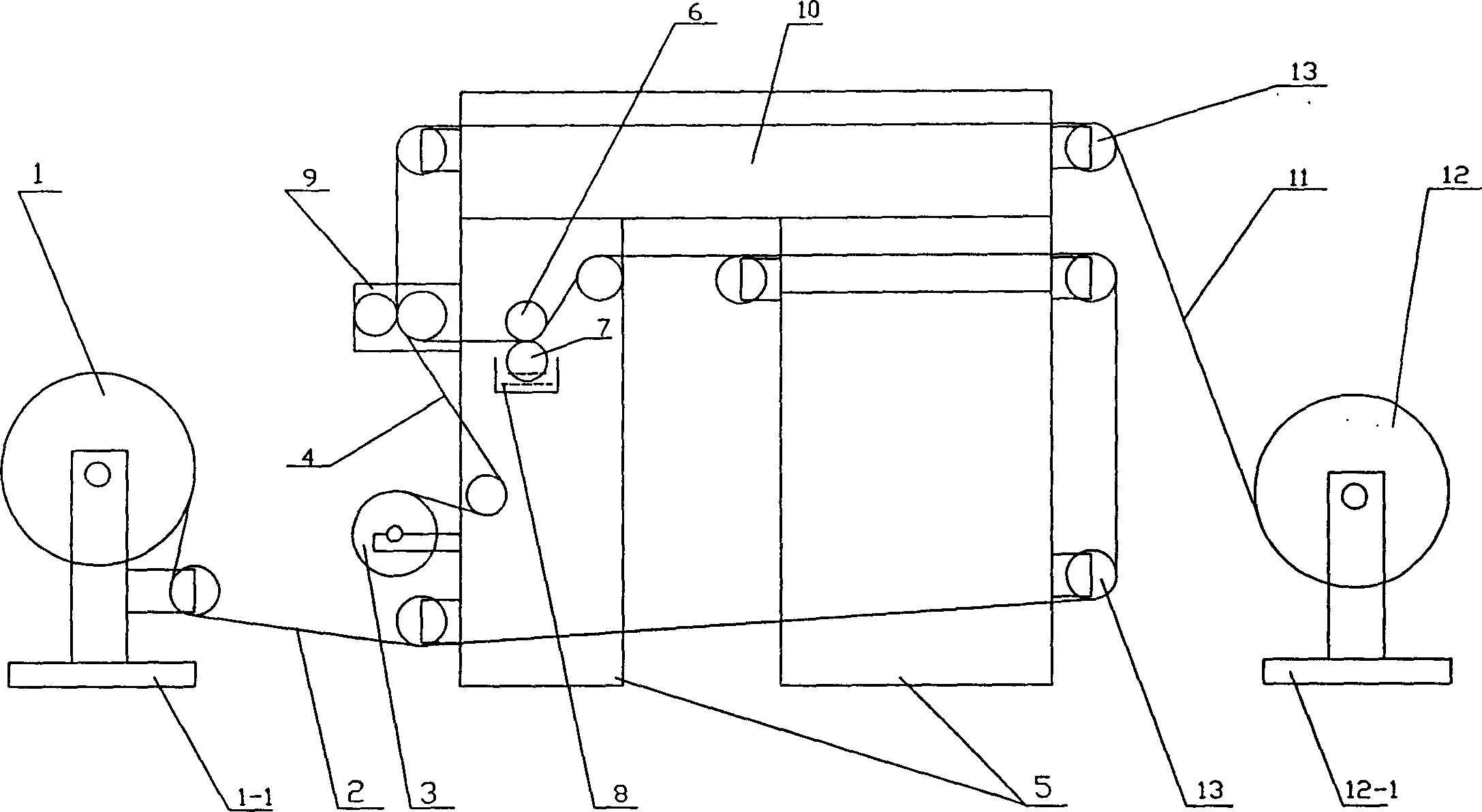

[0018] The production process of the wrapping paper is as follows: the gray board paper is coated with glue and pressed with the printed coated paper of 50-110 grams, and then dried in 3 ovens. The feeding tension of inner paper is 50-100MPa, the feeding tension of face paper is 30-100MPa, and the amount of glue applied to mesh roller is 5-30g / m 2 , the pressure of the glue roller is 4MPa, the temperature of the three ovens is > room temperature -120°C (such as 60°C), > room temperature -130°C (such as 70°C), > room temperature -150°C (such as 60°C), and the receiving tension is 20- 50MPa, paper feeding speed 100-...

Embodiment 2

[0020] Embodiment 2. In this embodiment, wood pulp paper is selected as the inner paper, and red pigment is added to the adhesive. Consumers can judge the authenticity of the product accordingly. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com