Automatic transmission

A technology of automatic transmission and gearbox, applied in the direction of vehicle gearbox, transmission element, transmission device, etc., can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

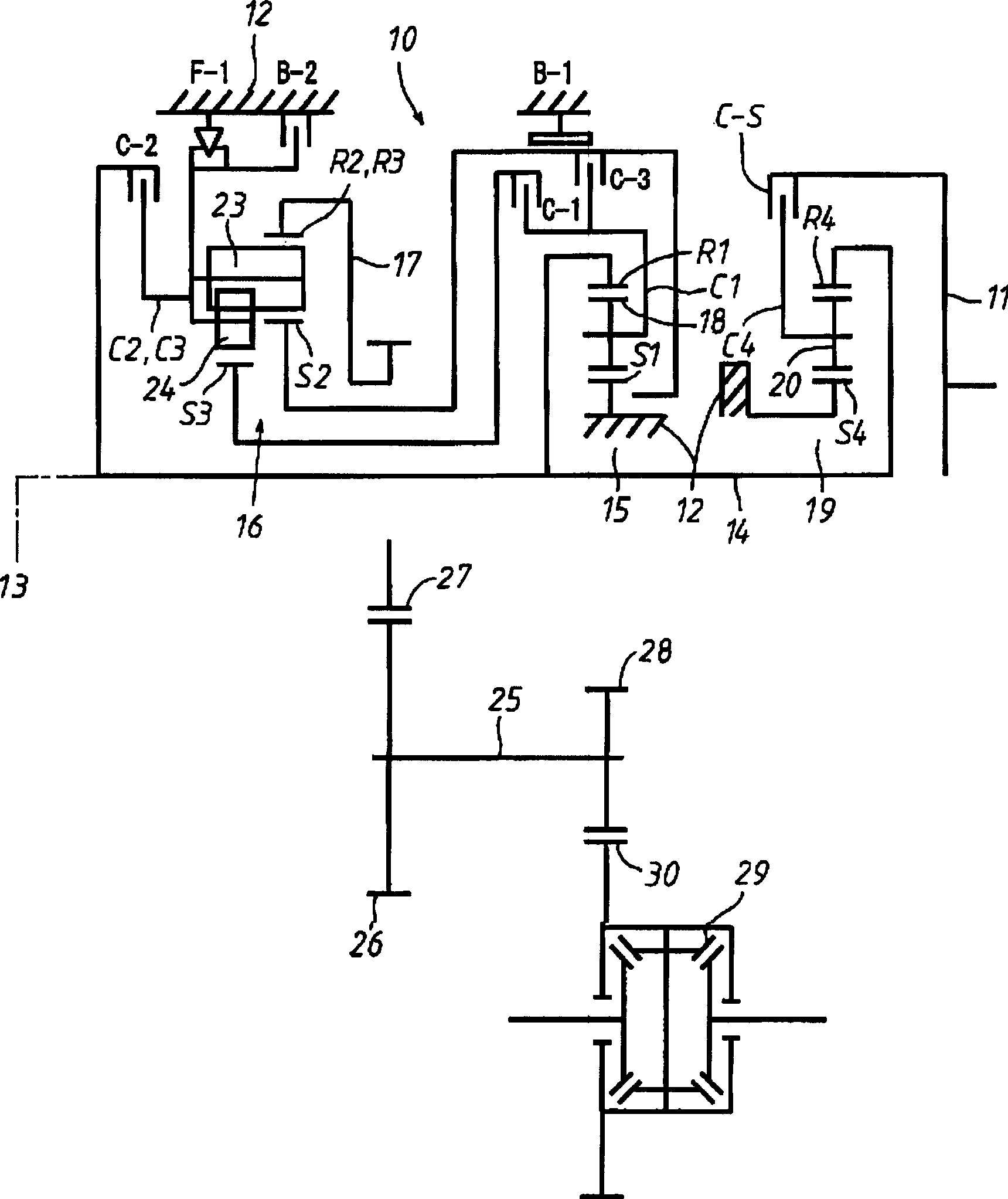

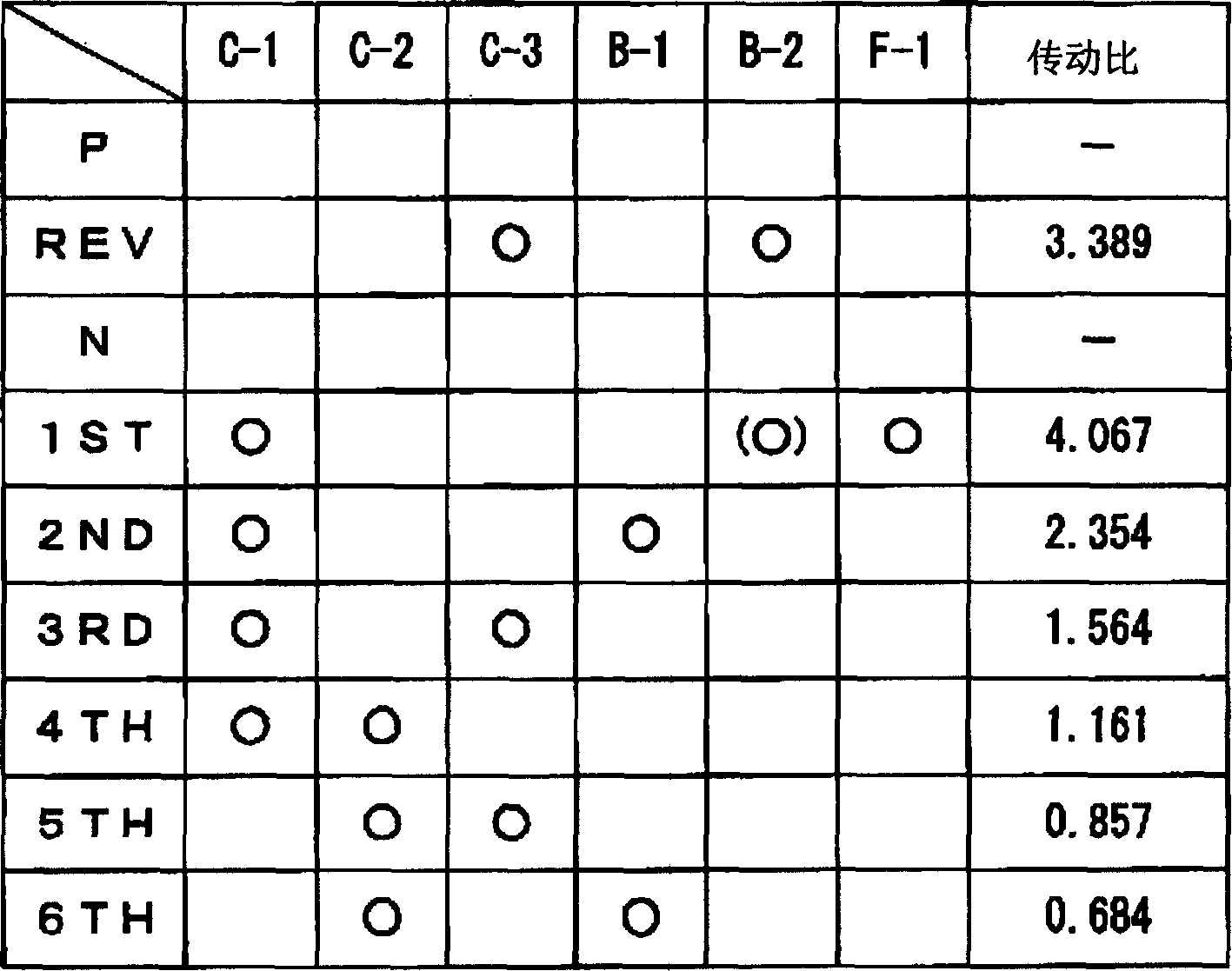

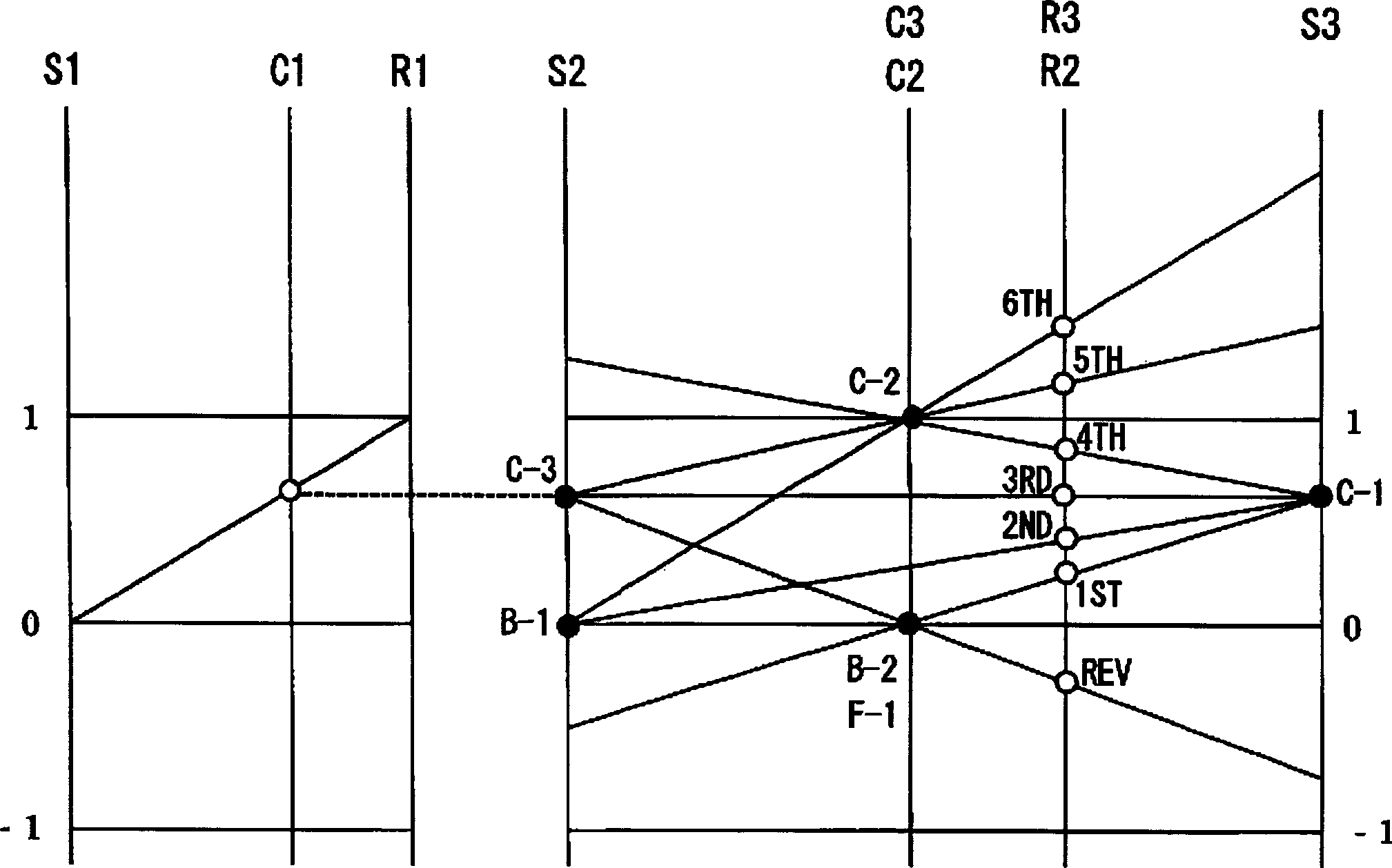

[0043] Hereinafter, embodiments of the automatic transmission according to the present invention will be described based on the drawings. In FIG. 1 , 10 is an automatic transmission according to the present invention, for example, for changing the speed of the rotation of a drive member 11 to which the output rotation of a diesel engine of an automobile is transmitted and transmitting it to drive wheels. The automatic transmission 10 is composed of the following parts: in the gearbox 12 installed in the vehicle body, the drive member 11 supported on the common axis 13, the planetary gear 19 for speed-up, the single planetary gear 15, the compound planetary gear 16, the output Shaft 17, starting clutch C-S, clutches C-1 through C-3, and brakes B-1, B-2.

[0044] The planetary gear 19 for speed-up is composed of the following components: the sun gear S4 fixed on the gearbox 12, the planetary gear carrier C4 that can be connected to the driving part 11 through the starting clutch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com