Tech. for drying rubber assistant

A drying process and technology of rubber additives, applied in dryer combination, drying solid materials, heating to dry solid materials, etc., can solve the problems of insufficient drying of materials, low drying rate of materials, small particle size of products, etc., and achieve drying efficiency. High, low process investment, enhanced disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

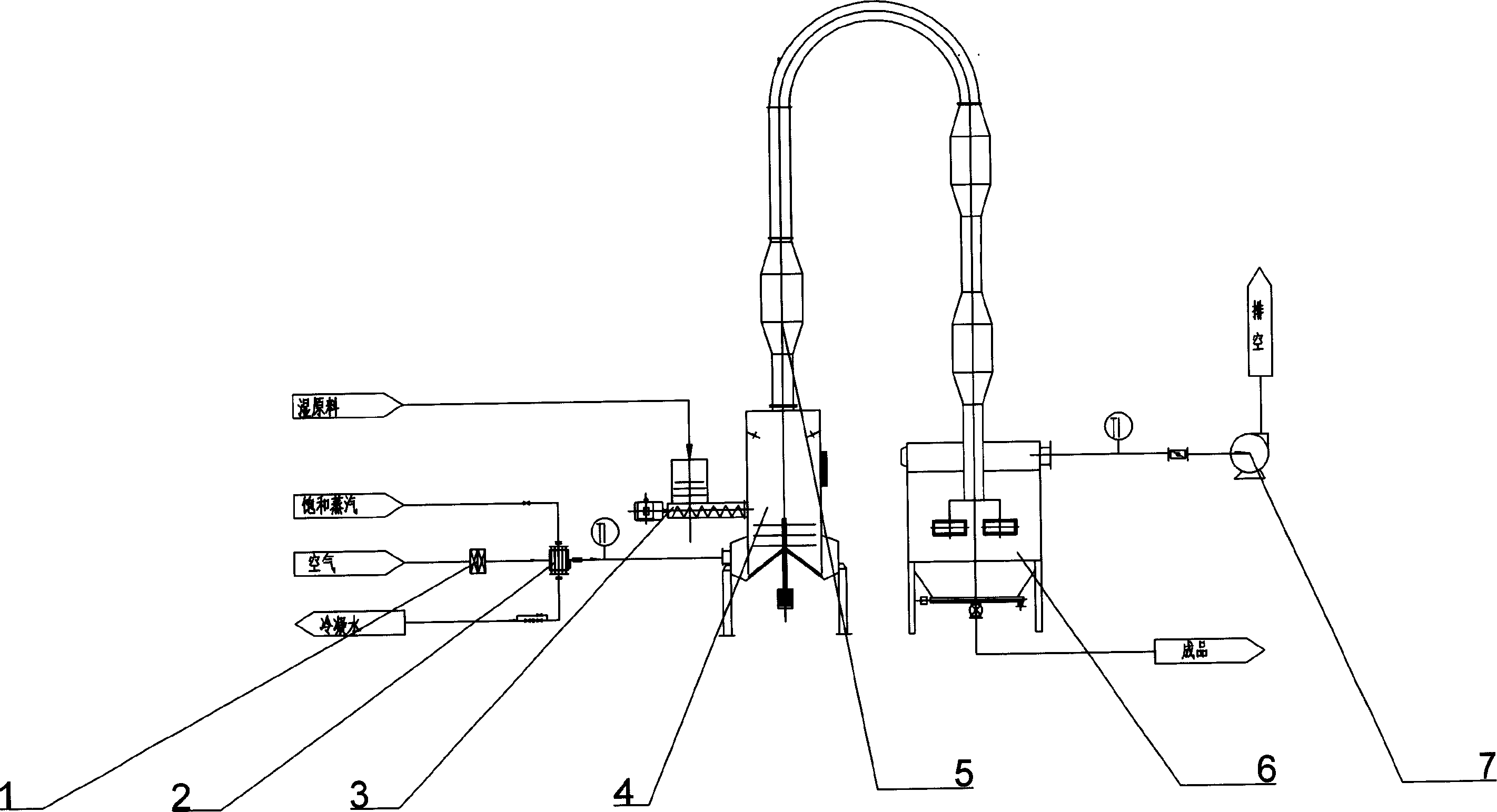

[0011] figure 1 In the process, the wet material enters the flash dryer 4 through the feeder 3, and the process air composed of air, condensed water and saturated steam is also sent into the flash dryer 4 after passing through the filter 1 and the heat exchanger 2. The flash dryer 4 breaks up the material and mixes it with high-temperature process air for drying, then the material is sent to the airflow dryer 5 for the second drying, and the dried material is sent to the bag filter 6 for dust collection, and the bag filter 6 and The fan 7 is connected, the process air after bag dust removal enters the fan 7 to be emptied, and the finished product can be sent out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com