Method for realizing high resolution degree three-dimensional imaging by projector producing translation surface fringe

A three-dimensional imaging, high-resolution technology, applied in the field of imaging, can solve the problems of computer identification difficulties, device manufacturing and processing difficulties, and complex solving operation processes, so as to achieve the improvement of three-dimensional space sampling accuracy and imaging efficiency, and to improve identification and differentiation. Ability, wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

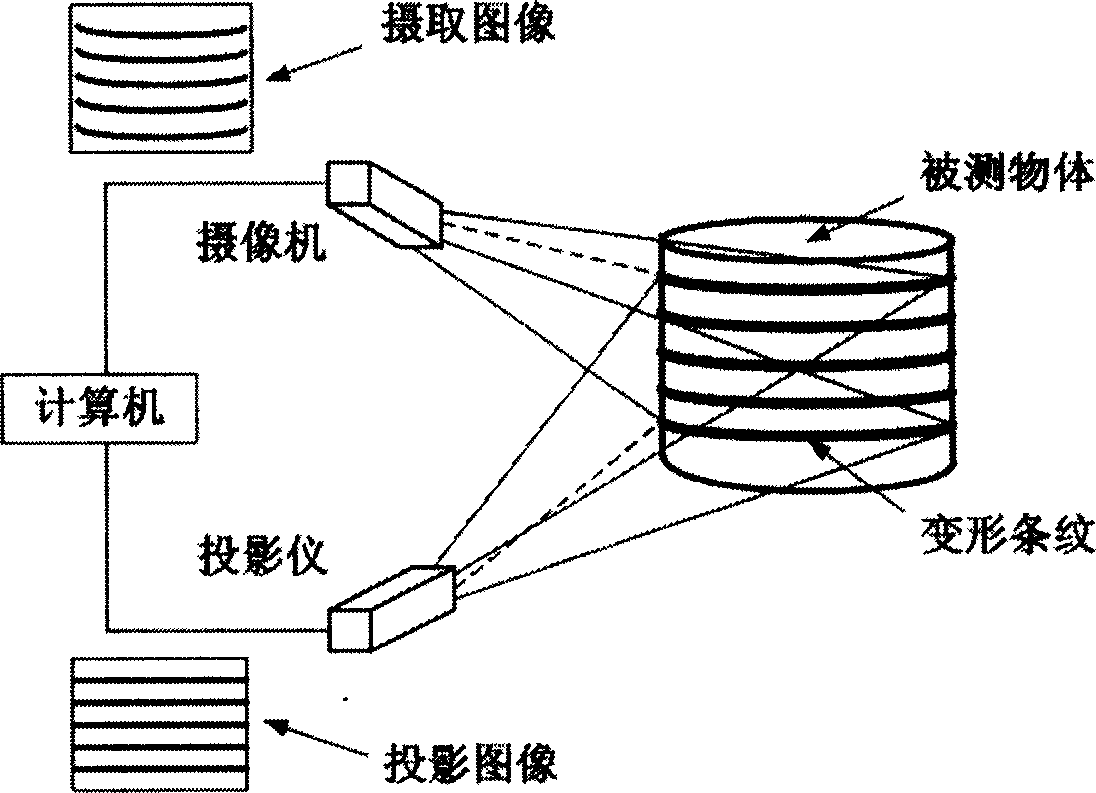

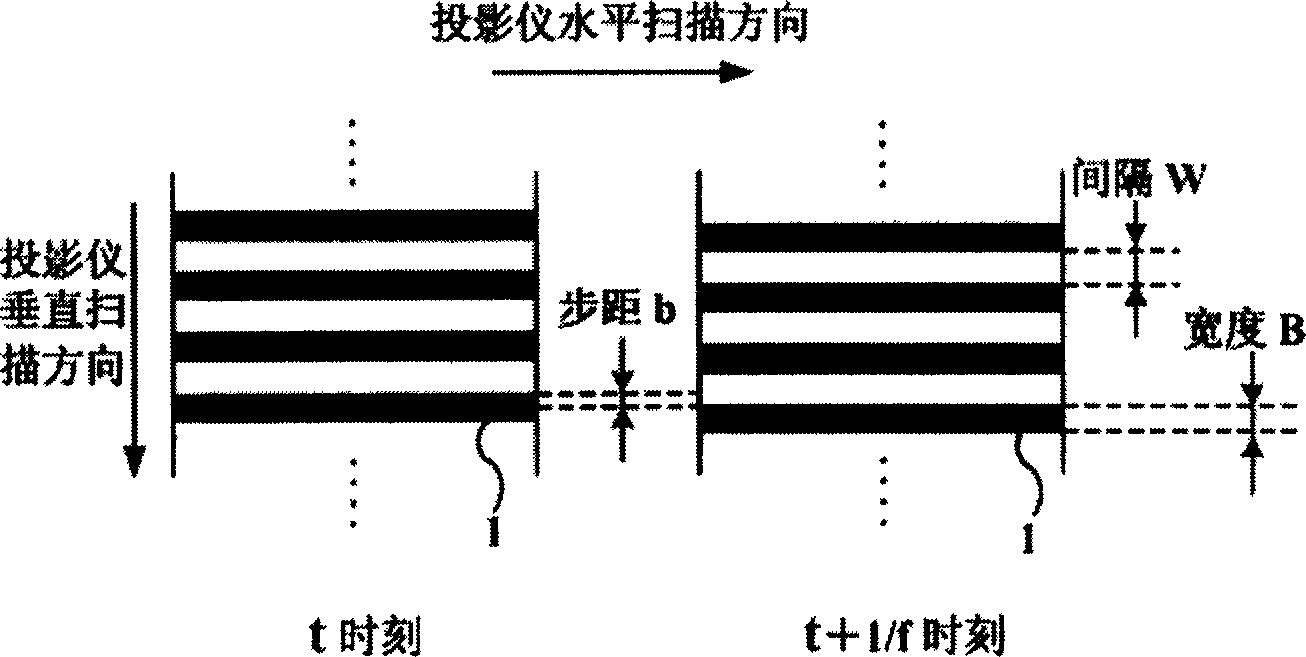

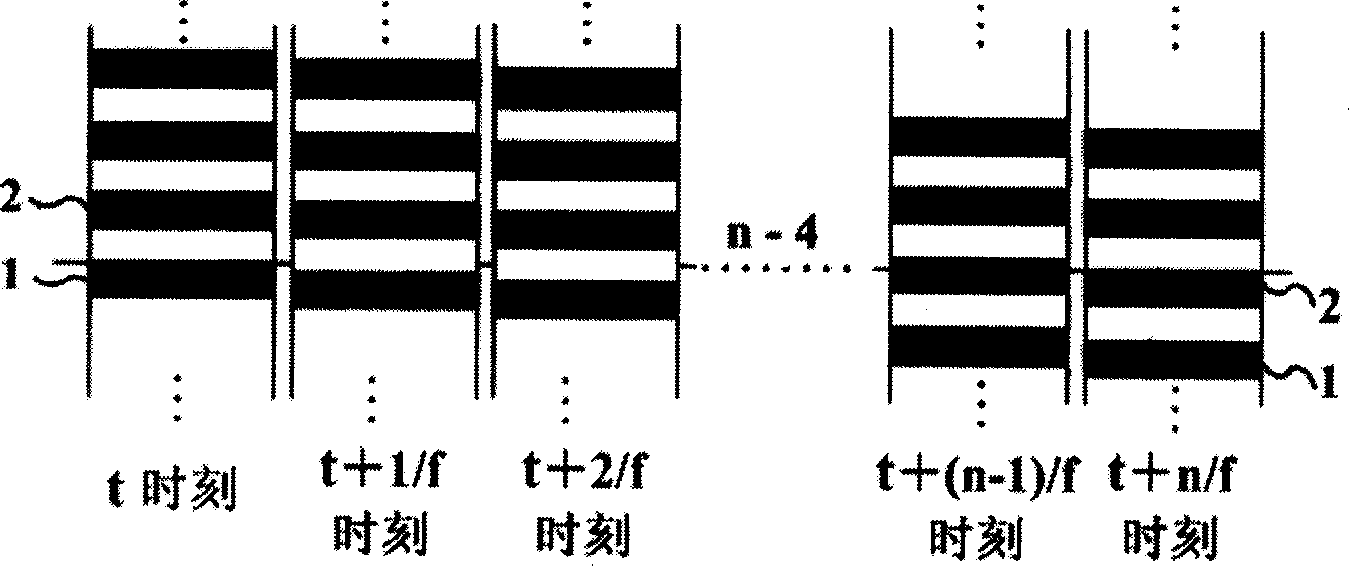

[0023] Such as figure 1 As shown, it is a schematic diagram of the basic principle of the present invention. The computer controls the projector and the camera. The projector emits a projected image and projects it onto the object to be measured. The area stripes in the projected image move in parallel according to the step frequency f. Deformation occurs when parallel area stripes are projected onto the object under test. The camera captures the image of the deformed area array fringe, and collects it into the computer through the image acquisition card. A common liquid crystal projector or the like may be used as the projector. The camera can be an ordinary CCD camera or a CMOS camera. The effective field of view of the three-dimensional imaging is the intersection area of the field of view of the projector an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com