Method for ingelligent optimizing procedure of semiconductor packing producing line

An intelligent optimization and production line technology, applied in semiconductor/solid-state device manufacturing, instruments, adaptive control, etc., can solve the problems of few simulation studies on semiconductor packaging production lines, complex and variable production systems, etc., and achieve a reasonable average occupancy rate of machines, Fast convergence speed and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

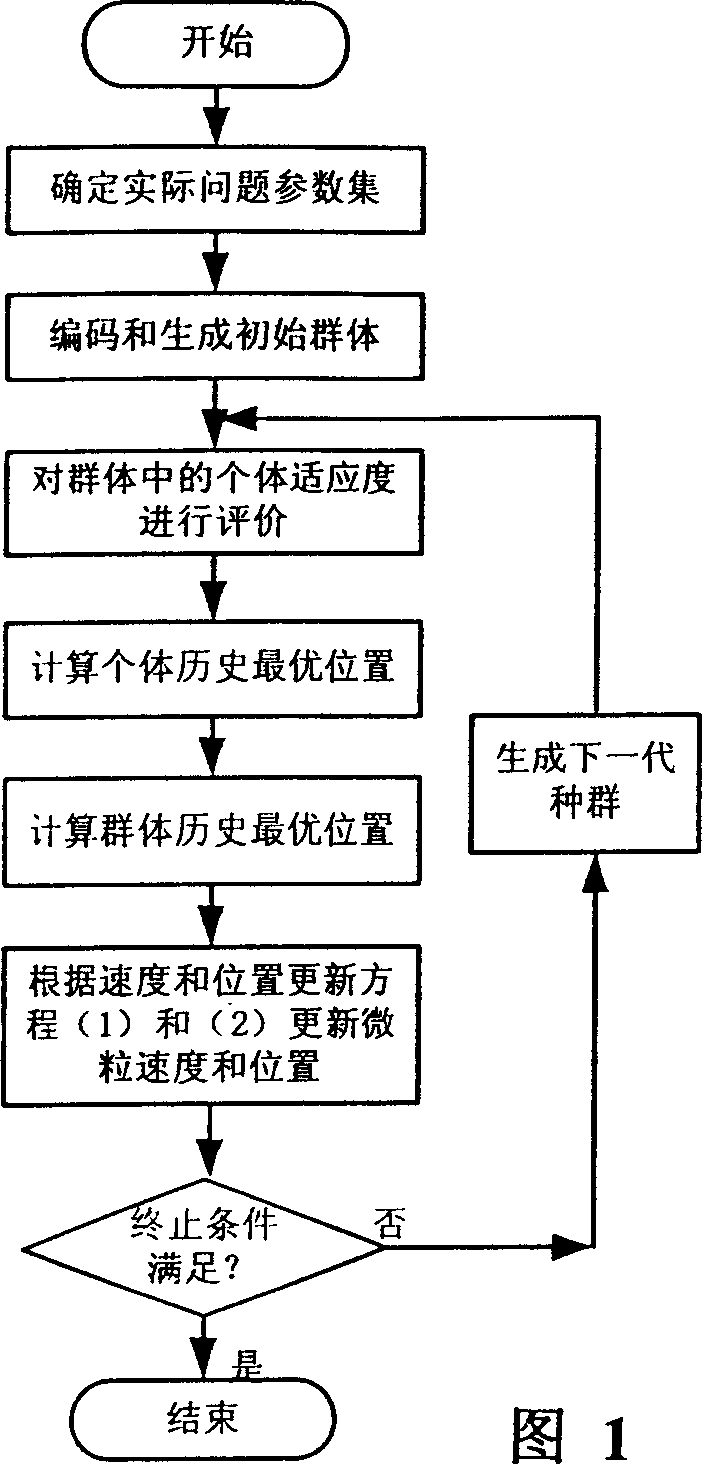

[0042] The principle of the particle swarm optimization algorithm used in the sub-problem optimization solution of the present invention is (see Figure 1):

[0043] The initial population consists of randomly generated solutions. The individuals in the population are called particles. The particles fly in the search space at a certain speed, which can be dynamically adjusted based on the flight experience of themselves and their companions. Suppose the size of the particle group is N, the particle i (i=1-N) is in D, and the coordinate position in the dimensional space can be expressed as x i =(xi1 , X i2 , K, x id , Kx iD ), the velocity of particle i is defined as the distance that the particle moves in each iteration, using v i =(v i1 , V i2 , K, v id , Kv iD ) Means. The flying speed v of the particle i in the d-th (d=1-D)-dimensional subspace id And the position update of the particles is adjusted according to the following two equations:

[0044] v id (t+1)=ωv id (t)+c 1 rand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com