Power tool housing

A technology for power tools and casings, applied in the field of transmission casings, can solve problems such as reducing battery life and reducing hammer drill efficiency, and achieve the effect of reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

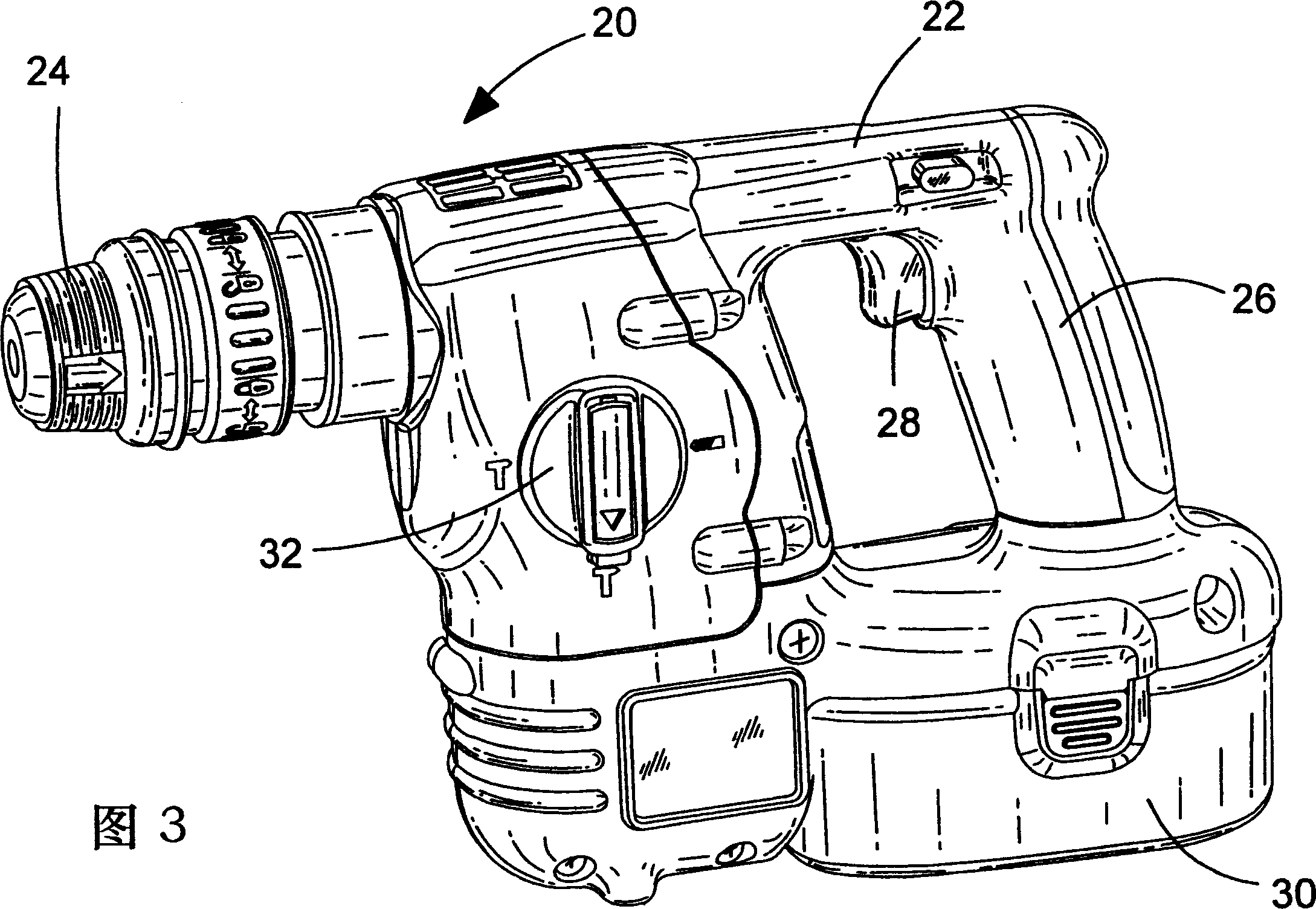

[0062]3, a battery-powered hammer drill includes a tool housing 22 and a chuck 24 for fixing a drill bit (not shown). The tool housing 22 is formed with a handle 26 having a trigger 28 for starting the hammer drill 20. The battery pack 30 is detachably connected to the bottom of the tool housing 22. The setting mode selection knob 32 is used to select between the hammer only mode, the rotation only mode and the hammer rotation combination mode of the drill operation.

[0063] Referring to FIG. 4, the motor 34 is provided in the tool housing 22 and has a rotating output shaft 36. A pinion gear 38 is formed at the end of the output shaft 36, and the pinion gear 38 meshes with the first drive gear 40 of the rotation drive mechanism and the second drive gear 42 of the hammer drive mechanism.

[0064] The rotation drive mechanism is described as follows. The first bevel gear 44 is driven by the first drive gear 40. The first bevel gear 44 meshes with the second bevel gear 46. The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com