Process for producing slow releasing silicon potassium compound fertilizer by potassium feldspar

A technology for compound fertilizer and potassium feldspar, which is applied in the production field of producing silicon-potassium compound fertilizer, can solve problems such as not being developed, and achieve the effects of solving the shortage of potash fertilizer, lowering the roasting temperature and cheap reserves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

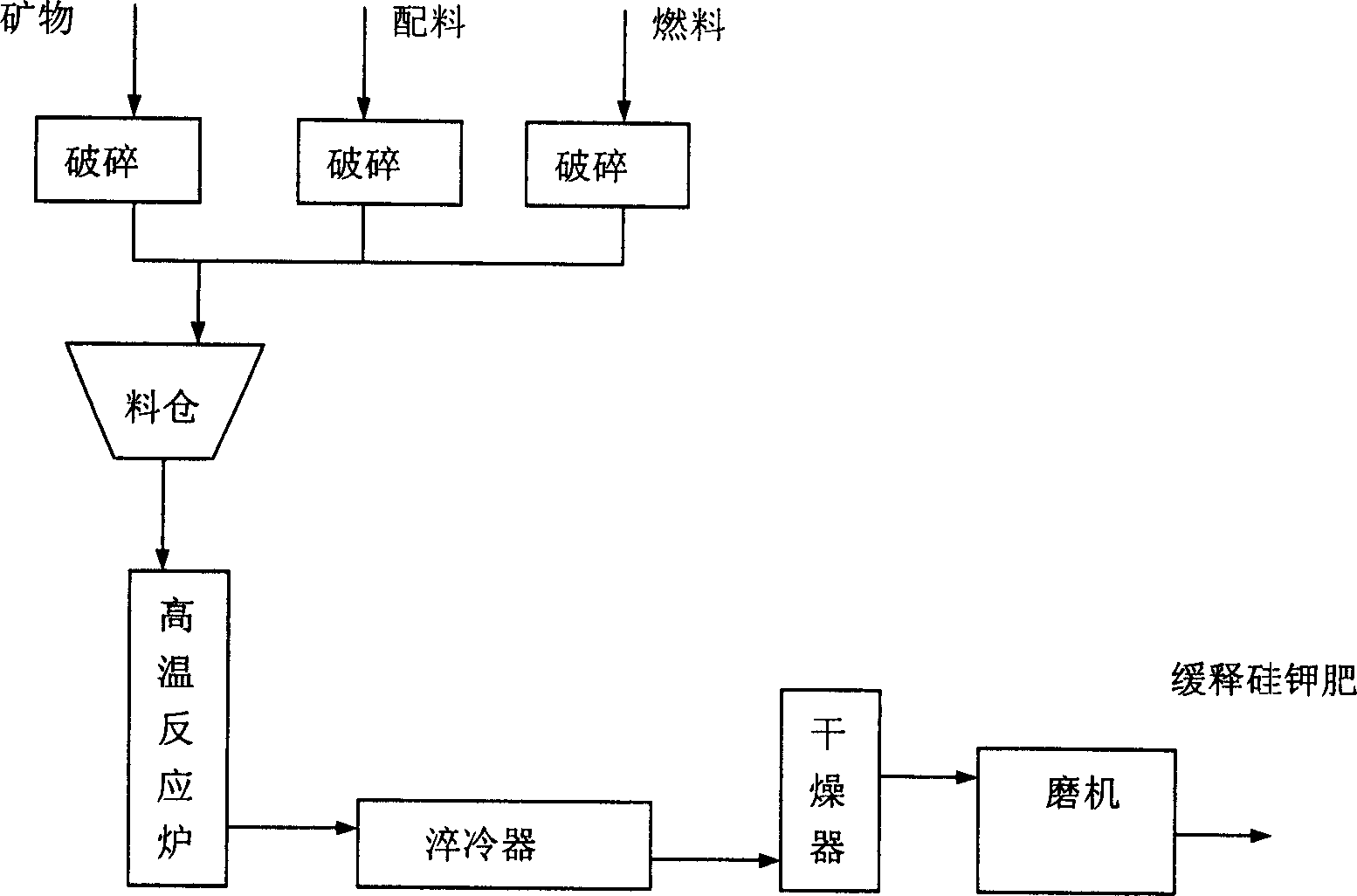

[0031] The method for producing slow-release composite silicon-potassium fertilizer with potassium feldspar, the technological process of the present embodiment is as attached figure 1 shown. Potassium feldspar and dolomite ore are crushed to a size of 15 to 30mm, and coke is crushed to a size of 30 to 60mm, and then placed in the feed bin according to the weight ratio of potassium feldspar: dolomite: coke = 1:1.2:2.4 Proceed to the ingredients. In this embodiment, the proportions by weight of potassium feldspar, dolomite and coke can be in the range of 1:0.6-2.0:2.0-2.8. The prepared raw materials are put into a high-temperature reaction furnace for roasting, the roasting temperature is controlled at about 1300°C (range of 1250-1450°C), and the roasting time is about 1 hour. After the roasting is completed, the molten slurry is quenched by impacting with water, cooled to ambient temperature to form a sand-like semi-finished product, and after drying, it is crushed into a po...

Embodiment 2

[0033] The method for producing slow-release compound silicon-potassium fertilizer with potassium feldspar, the process flow of this embodiment is basically as attached figure 1 As shown, only the drying section is missing. Potassium feldspar, dolomite, and serpentine ore are crushed to a size of 5-15 mm, coke is crushed to a size of 10-30 mm, and then potassium feldspar: dolomite: serpentine: coke = 1: 0.6: 0.8: The ratio of parts by weight of 2.5 is batched in the silo. In this embodiment, the proportions by weight of potassium feldspar, dolomite, serpentine and coke can be in the range of 1:0.4-1.2:0.6-1.0:2.2-3.0. The prepared raw materials are put into a high-temperature reaction furnace for roasting, the roasting temperature is controlled at about 1400°C (the range of 1250-1450°C), and the roasting time is about 1.5 hours. After the roasting is completed, the molten slurry is dispersed by air flow for quenching, cooled to ambient temperature to form a sand-like semi-fi...

Embodiment 3

[0035] The method for producing slow-release composite silicon-potassium fertilizer with potassium feldspar, the technological process of the present embodiment is as attached figure 1 As shown, it is basically the same as Example 1. Potassium feldspar, dolomite, serpentine, and gypsum ore are crushed to a size of 15-20mm, coke is crushed to a size of 30-50mm, and then potassium feldspar: dolomite: serpentine: gypsum: coke = 1: The ratio of parts by weight of 1.6:1.8:1.0:2.6 is batched in the silo. In this embodiment, the proportions by weight of potassium feldspar, dolomite, serpentine, gypsum and coke can be in the range of 1: 1.0-1.6: 1.6-2.2: 0.5-2.6: 2.0-2.6. The prepared raw materials are put into a high-temperature reaction furnace for roasting, the roasting temperature is controlled at about 1550°C (1350-1550°C range), and the roasting time is about 2.5 hours. After the roasting is completed, the molten slurry is dispersed with gas and water for quenching, cooled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com