Polychloroethylene processing modifier and its preparation process and application thereof

A technology for processing modifiers and polyvinyl chloride, which is applied in the field of modifying additives for polyvinyl chloride processing, can solve the problems of inability to obtain processing modifiers and polymerization reactions, etc., and achieve improved smoothness, improved processing performance, Effect of improving plasticizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

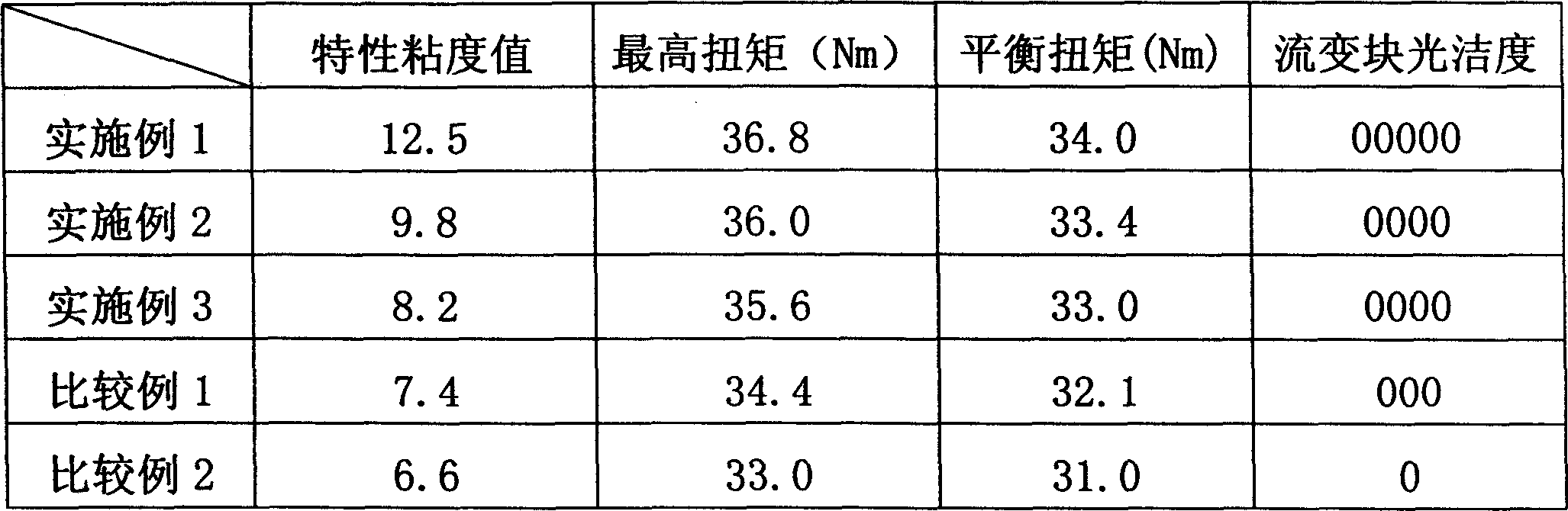

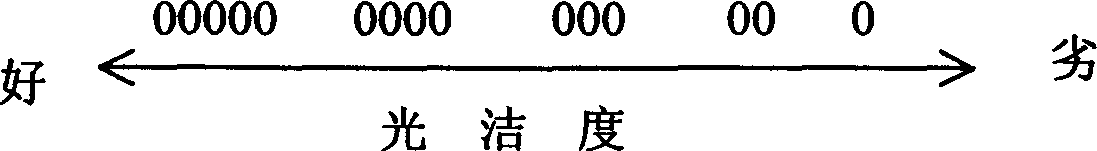

Embodiment 1

[0029] Example 1 Put 120 parts by weight of water, 75 parts by weight of styrene, 25 parts by weight of acrylonitrile, 1.1 parts by weight of sodium lauryl sulfate, and 0.01 parts by weight of potassium persulfate into the reactor at one time, Raise the temperature to 50°C at a stirring speed of 200 rpm, and keep the temperature below 55°C for 20 hours to obtain an emulsion of styrene and acrylonitrile copolymer, and obtain styrene and acrylonitrile with an intrinsic viscosity of 12.5 after drying class of copolymers.

Embodiment 2

[0030] Example 2 Put 120 parts by weight of water into the reactor at one time, then add 75 parts by weight of styrene, 25 parts by weight of acrylonitrile, 1.1 parts by weight of sodium lauryl sulfate, and 0.01 parts by weight of persulfuric acid Potassium is put into the reactor twice, and the order of addition is that the first monomer is reacted and then the second monomer is added, and the temperature is raised to 50°C at a stirring speed of 200 rpm, and the temperature Keep the reaction temperature below 55°C for 20 hours to obtain a styrene-acrylonitrile copolymer emulsion, and obtain a styrene-acrylonitrile copolymer with an intrinsic viscosity of 9.8 after drying.

Embodiment 3

[0031] Example 3 Same as Example 2, except that the reaction mixture was added into the reactor three times to obtain a styrene-acrylonitrile copolymer with an intrinsic viscosity of 8.2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap