Process for preparing iron base non crystal state alloy by bar material plasma spraying

An amorphous alloy, iron-based amorphous technology, applied in metal material coating process, coating, fusion spraying, etc., can solve the problem that only amorphous alloy powder can be used for amorphous alloy, and achieve excellent The effects of magnetic properties, high amorphous content, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

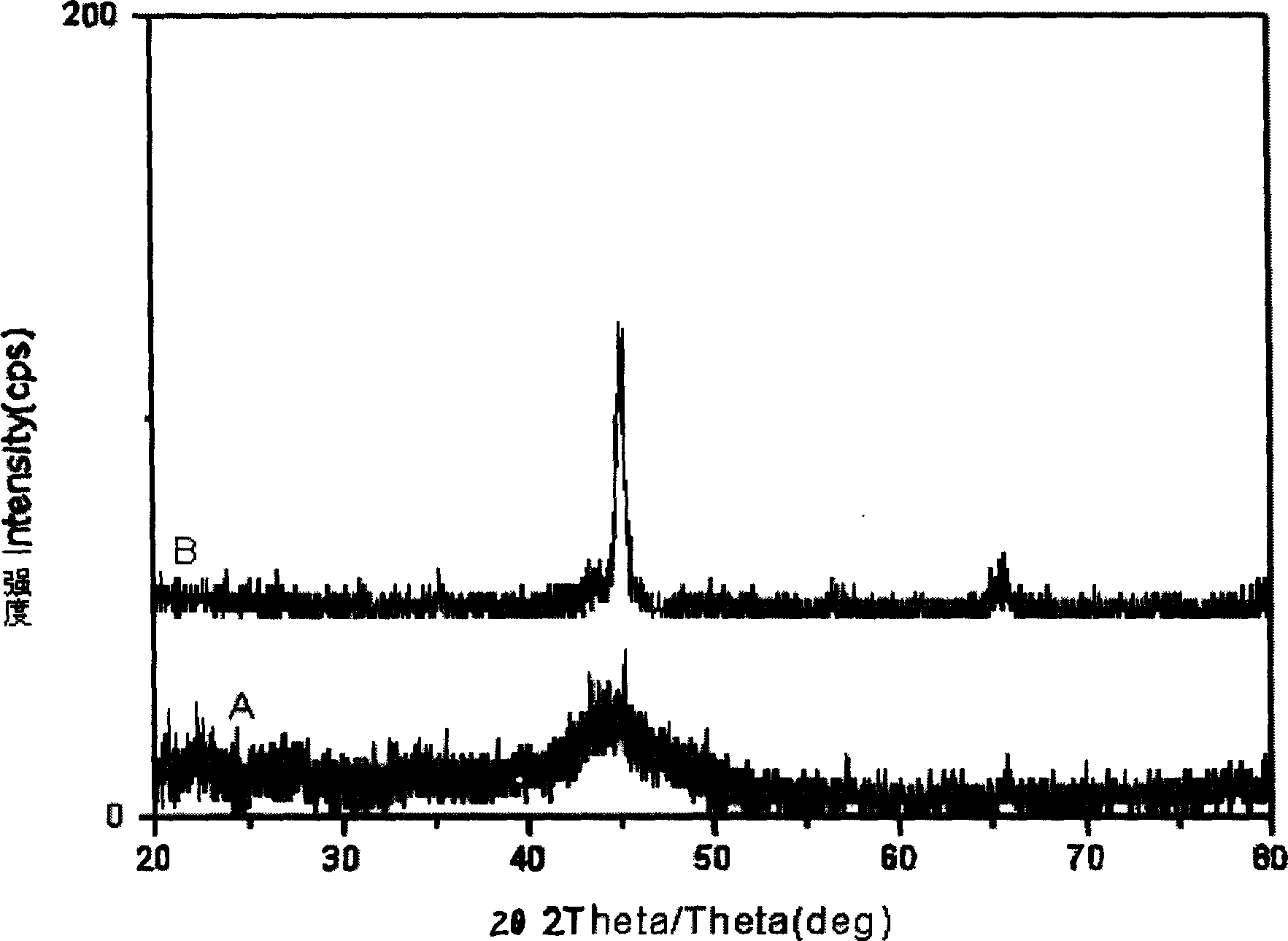

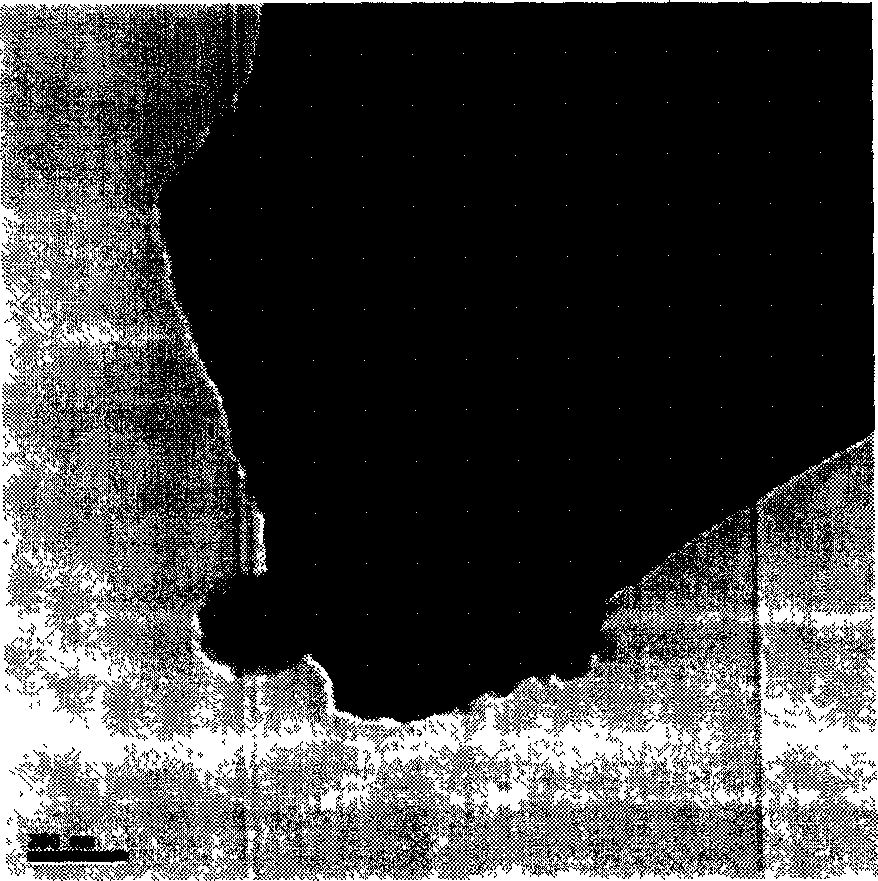

Embodiment 1

[0023] Select industrial pure iron: Si0.025, Mn0.15, P0.01, S0.026, C0.002, industrial ferroboron: B18.24, Si0.82, C0.4, Al0.27, industrial ferrosilicon: Si75 .25, S0.018, C0.09, P0.03, Mn0.36, Cr0.27, according to Fe 79 Si 10 B 11 Ratio Melting into a master alloy in an intermediate frequency vacuum induction furnace, and then preparing a rod with a diameter of 3 mm; the rod is continuously conveyed to the nozzle of the plasma spraying equipment through the rod feeding mechanism, and the rotation of the copper rod is controlled in the atmospheric environment The speed is 15r / s, the distance between the rod and the nozzle is 4mm, the rod feeding speed is 50mm / min, and the process parameters of the plasma spraying equipment are controlled at the same time: hydrogen pressure 0.25Mpa, argon pressure 0.85Mpa, voltage 55V, current 600A, spraying distance 100mm, the plasma spraying equipment is heated and atomized to spray on the rotating and cooled copper rod to obtain the iron-b...

Embodiment 2

[0025] Select industrial pure iron: Si0.025, Mn0.15, P0.01, S0.026, C0.002, industrial ferroboron: B18.24, Si0.82, C0.4, Al0.27, industrial ferrosilicon: Si75 .25, S0.018, C0.09, P0.03, Mn0.36, Cr0.27, according to Fe 80 Si 10 B 10 Ratio Melting into a master alloy in an intermediate frequency vacuum induction furnace, and then preparing a rod with a diameter of 4 mm; the rod is continuously conveyed to the nozzle of the plasma spraying equipment through the rod feeding mechanism, and the rotation of the copper rod is controlled in the atmospheric environment The speed is 20r / s, the distance between the rod and the nozzle is 3mm, the rod feeding speed is 40mm / min, and the process parameters of the plasma spraying equipment are controlled at the same time: hydrogen pressure 0.30Mpa, argon pressure 0.85Mpa, voltage 70V, current 650A, spraying distance 120mm, the plasma spraying equipment is heated and atomized to spray on the rotating and cooled copper rod to obtain the iron-b...

Embodiment 3

[0027] Select industrial pure iron: Si0.025, Mn0.15, P0.01, S0.026, C0.002, industrial ferrophosphorus: P0.24, Si0.02, C0.08, S0.004, Mn0.015, nodular graphite Cast iron: C0.036, Si0.021, Mn0.0052, P0.0005, according to Fe 80 P 13 C 7 Ratio Melting into a master alloy in an intermediate frequency vacuum induction furnace, and then preparing a rod with a diameter of 2 mm; the rod is continuously conveyed to the nozzle of the plasma spraying equipment through the rod feeding mechanism, and the rotation of the copper rod is controlled in the atmospheric environment The speed is 15r / s, the distance between the rod and the nozzle is 5mm, the rod feeding speed is 80mm / min, and the process parameters of the plasma spraying equipment are controlled at the same time: hydrogen pressure 0.30Mpa, argon pressure 0.70Mpa, voltage 50V, current 600A, spraying distance 80mm, the plasma spraying equipment is heated and atomized instantaneously and sprayed onto the rotating and cooled copper r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com