Nanometer structure micro mechanical biochemical sensor

A technology of biochemical sensors and nanostructures, applied in instruments, analytical materials, fuel oil testing, etc., can solve the problems of low sensitivity, slow adsorption rate, poor accuracy, etc., and achieve the effect of improving sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

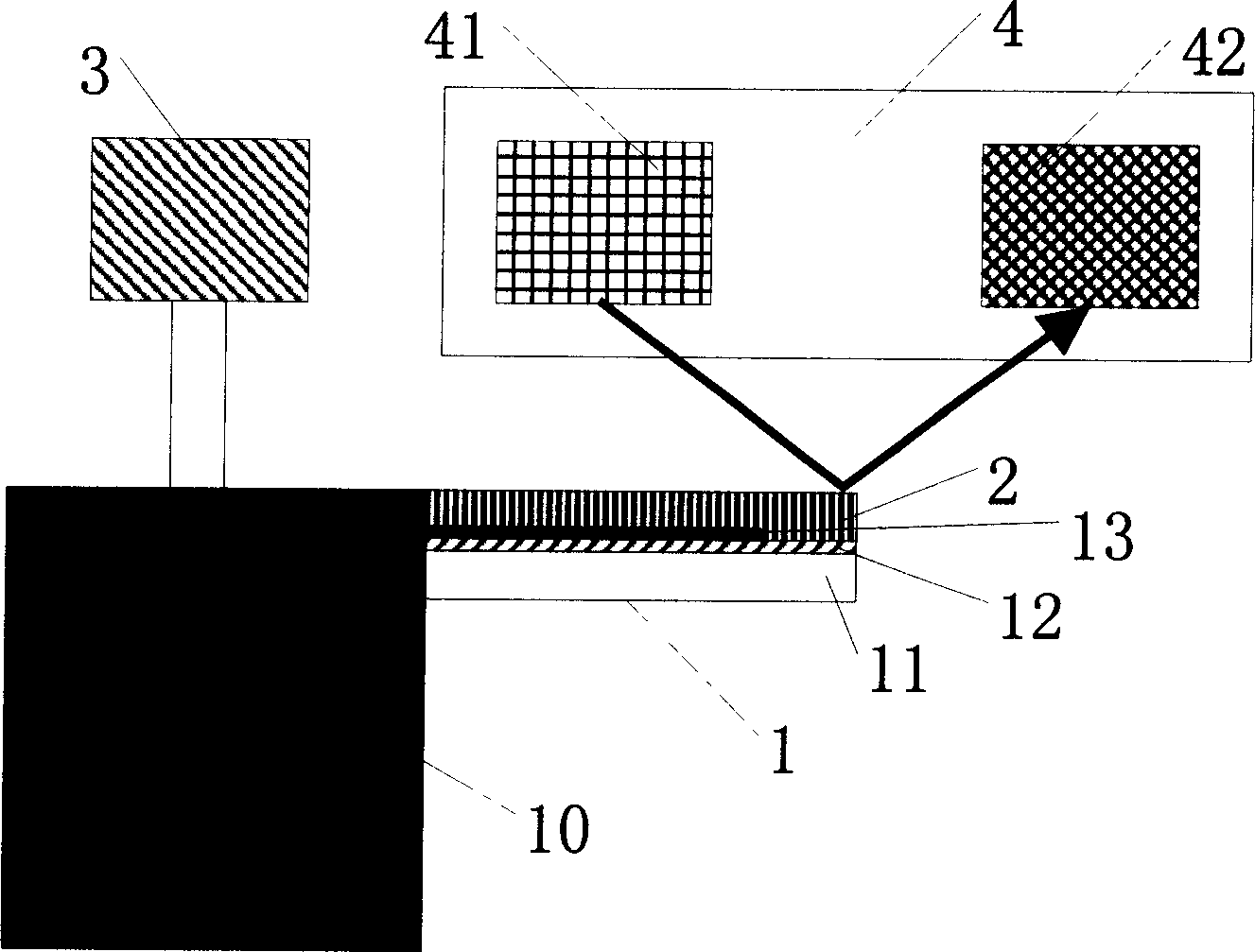

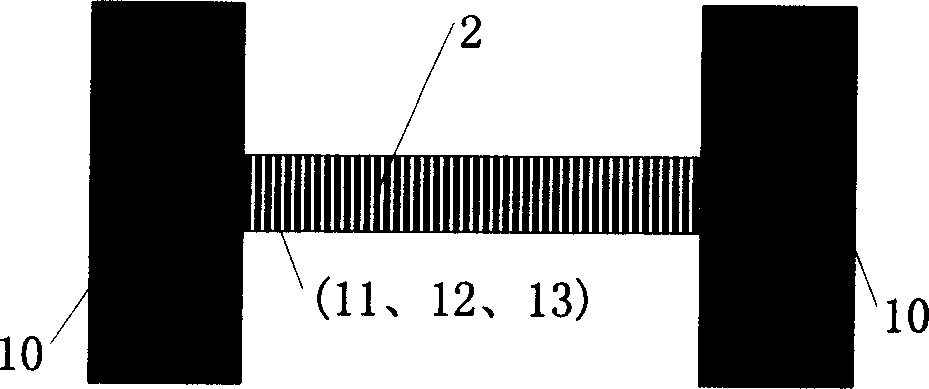

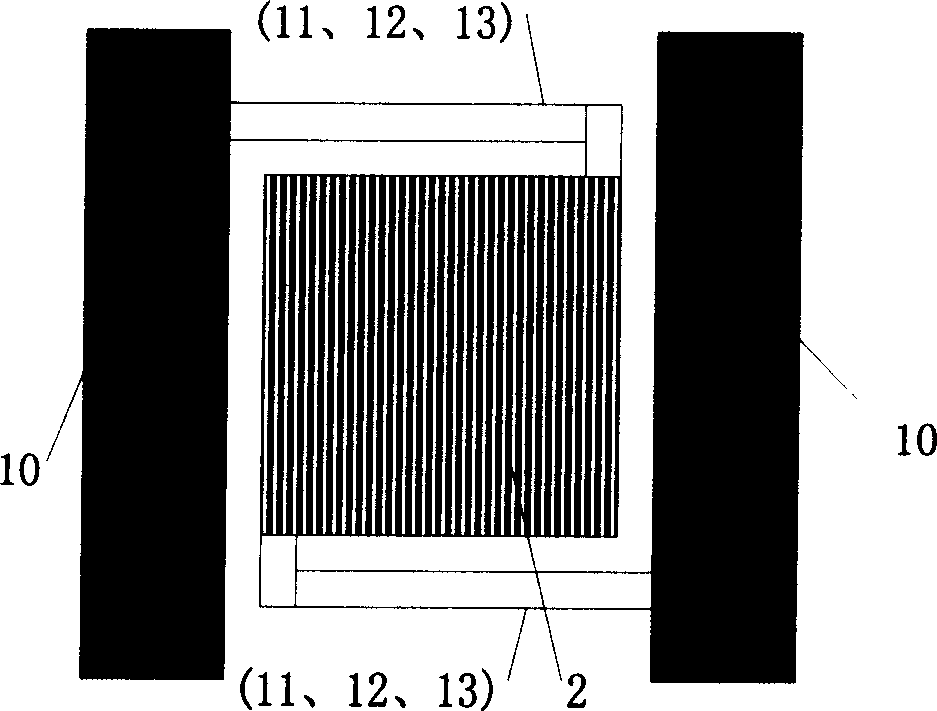

[0015] The invention provides a nanostructure micromechanical biochemical sensor with high sensitivity and simple structure for detecting various gases including explosive gas. The design mechanism of the present invention is: the nano-material grown on the micro-mechanical structure absorbs explosive gas, and the applied pulse voltage rapidly heats the nano-material adsorbed explosive gas through the heating resistance, so that the temperature exceeds the explosion of molecules such as explosives. Points, detonate explosive molecules and other gases, the explosion causes deformation of the micro-mechanical structure, use optical methods, capacitance, piezoelectric or piezoresistive methods to detect the deformation to obtain the output signal of the sensor, and realize the detection of explosive gas. The micromechanical structure can be prepared using SOI silicon wafers, and the resistance for heating nanomaterials and the piezoresistor for detecting sensor deformation are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com