Adhesive sheet, dicing tape intergrated type adhesive sheet, and semiconductor device producing method

A technology for cutting tapes and adhesive sheets, which is applied in semiconductor/solid-state device manufacturing, bonding methods, semiconductor devices, etc., and can solve problems such as cracking, reduced bonding reliability, and difficulty in cutting at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

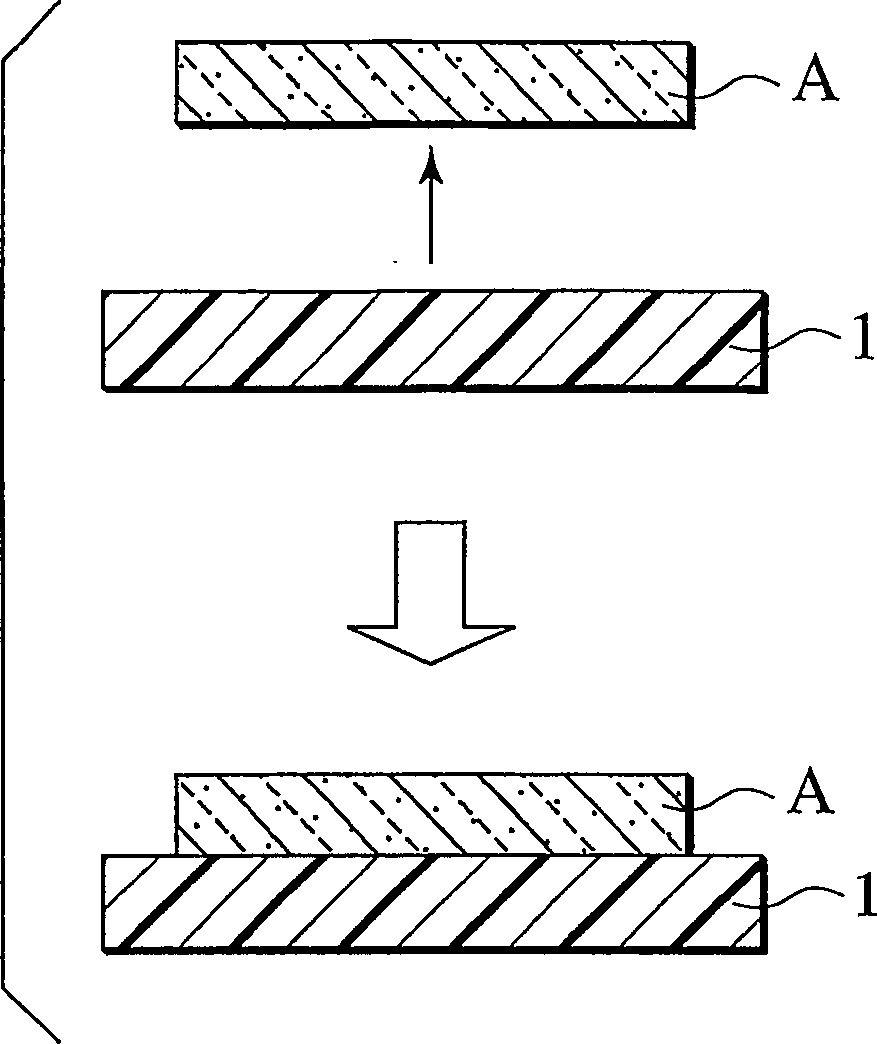

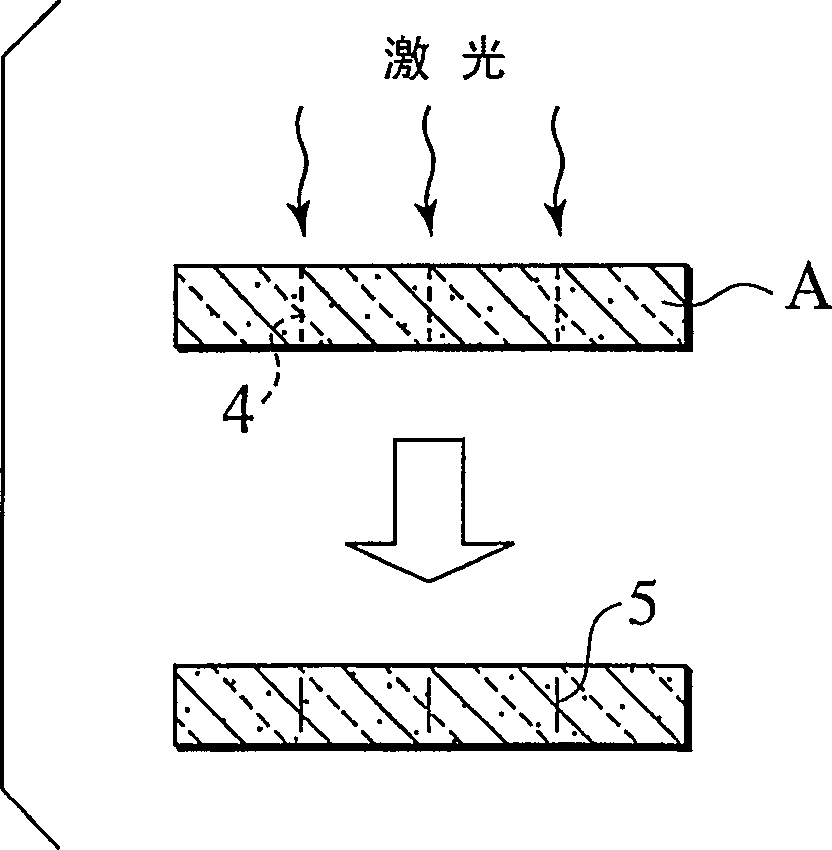

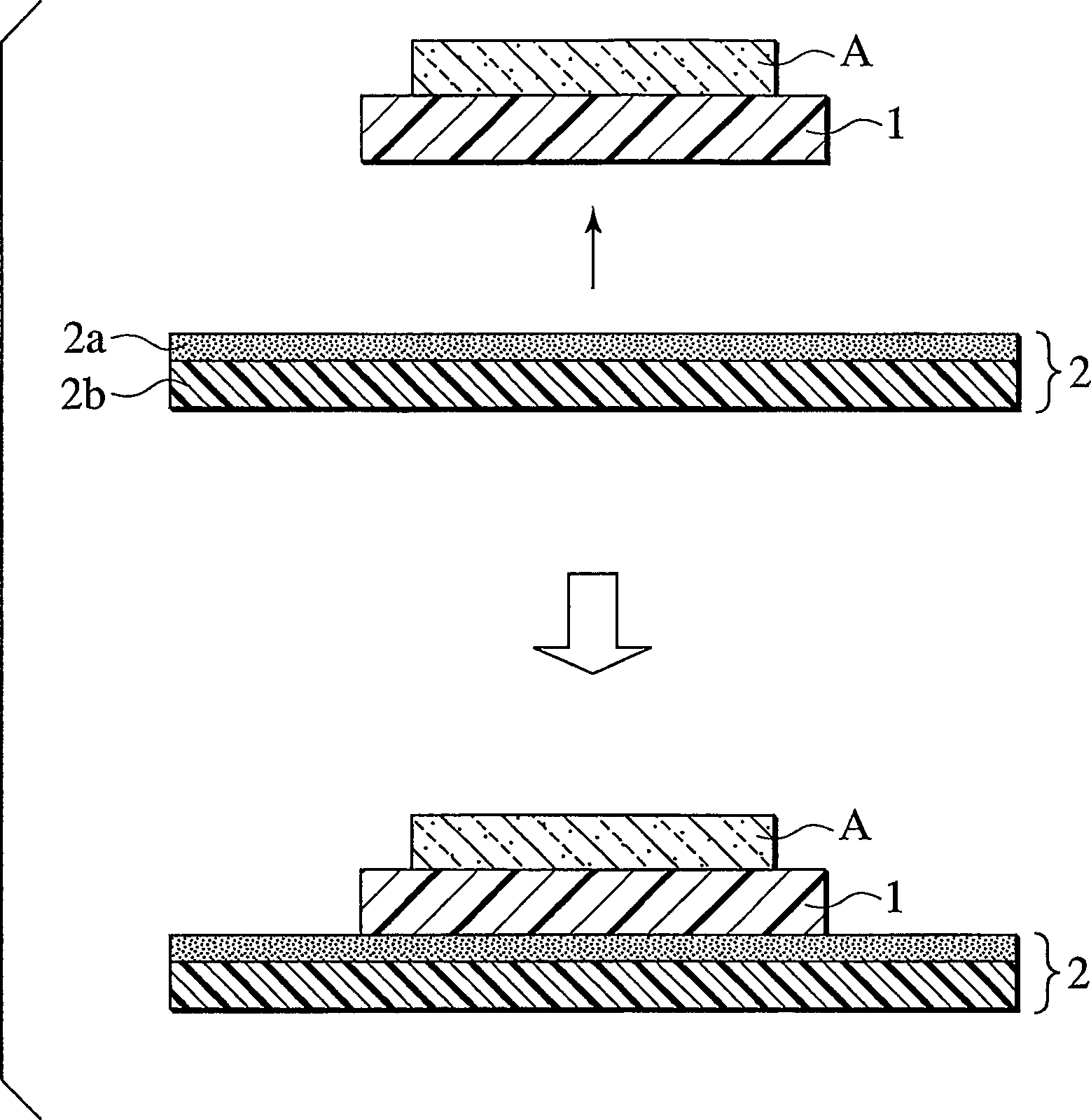

Method used

Image

Examples

Embodiment 1

[0113] Epoxy resin uses bisphenol F type epoxy resin (epoxy group equivalent is 160, and East Capital Chemical Co., Ltd. manufactures, trade name is YD-8170C) 30 weight parts; The block type epoxy resin of cresol (epoxy group The equivalent is 210, manufactured by Tohto Chemical Co., Ltd., trade name YDCN-703) 10 parts by weight: the hardener of epoxy resin uses the block resin of phenol (manufactured by Dainippon Inki Chemical Industry Co., Ltd., trade name is プテイオ- フエンLF2882) 27 parts by weight; The acrylic rubber containing epoxy group (the weight average molecular weight that gel permeation chromatography method records as the acrylic system copolymer containing epoxy group is 800,000, glycidyl methacrylate 3 weight parts %, Tg is-7 DEG C, manufactured by Nagase Chemtex, trade name is HTR-860P-3DR) 28 parts by weight; as hardening accelerator imidazole series hardening accelerator (Shikoku Chemical Industry Co., Ltd. manufactures キエアゾル 2PZ-CN) 0.1 Parts by weight; Silica fi...

Embodiment 2~6

[0116] Using the compositions shown in Table 1, an adhesive sheet was prepared in the same manner as in Example 1. The PSA sheet of Example 6 is a PSA sheet obtained in Example 1, which was heat-treated at 40° C. for 24 hours to reduce the elongation at break.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap