Detachable supercharger of single-cylinder internal combustion engine

A technology of supercharging device and internal combustion engine, which is applied to combustion engines, mechanical equipment, engine components, etc., can solve problems such as unreasonable belt transmission mode, inability to adapt to the supercharging requirements of internal combustion engines, and insignificant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

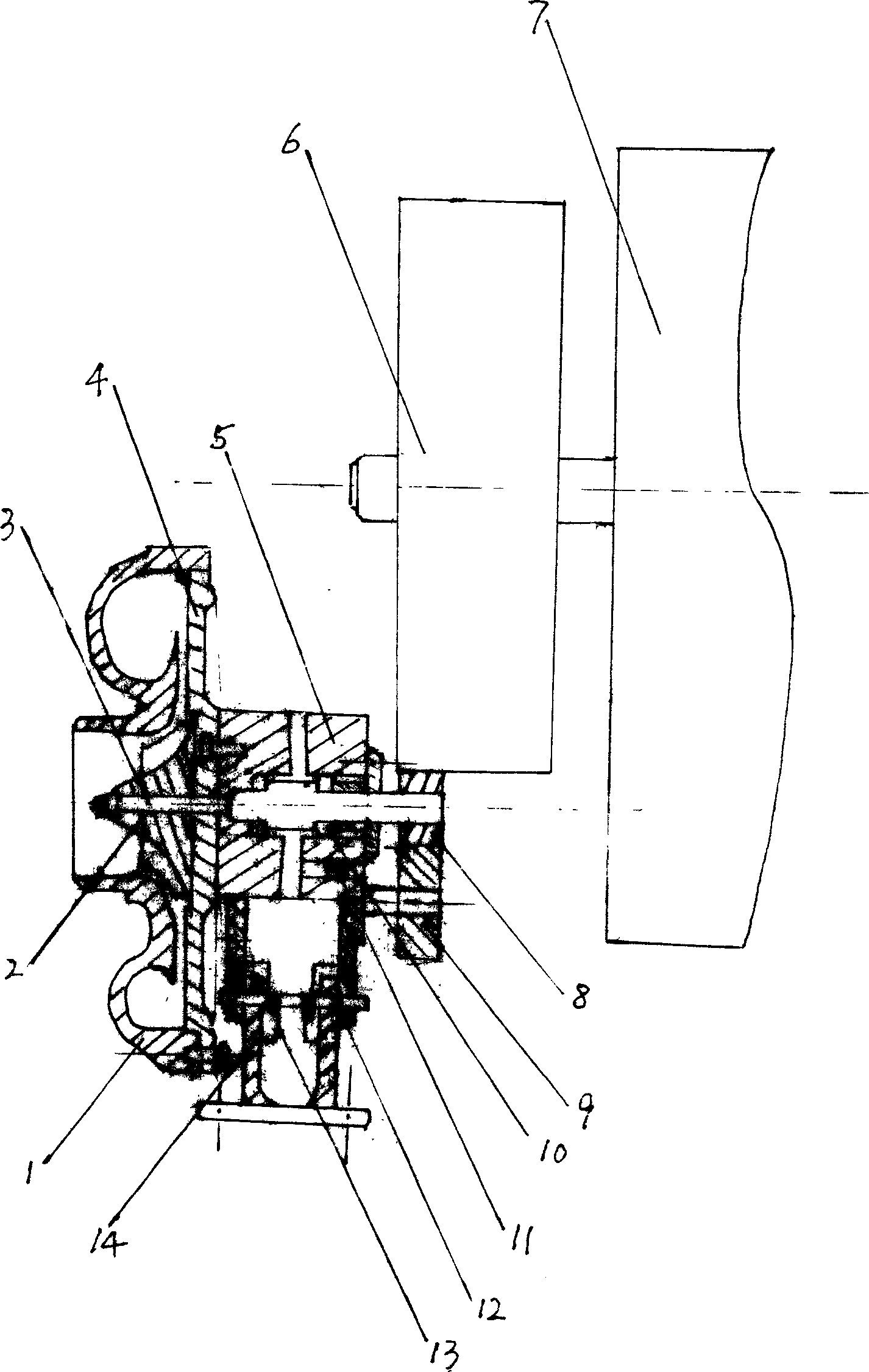

[0005] attached figure 1 It is a schematic diagram of the structure of the present invention.

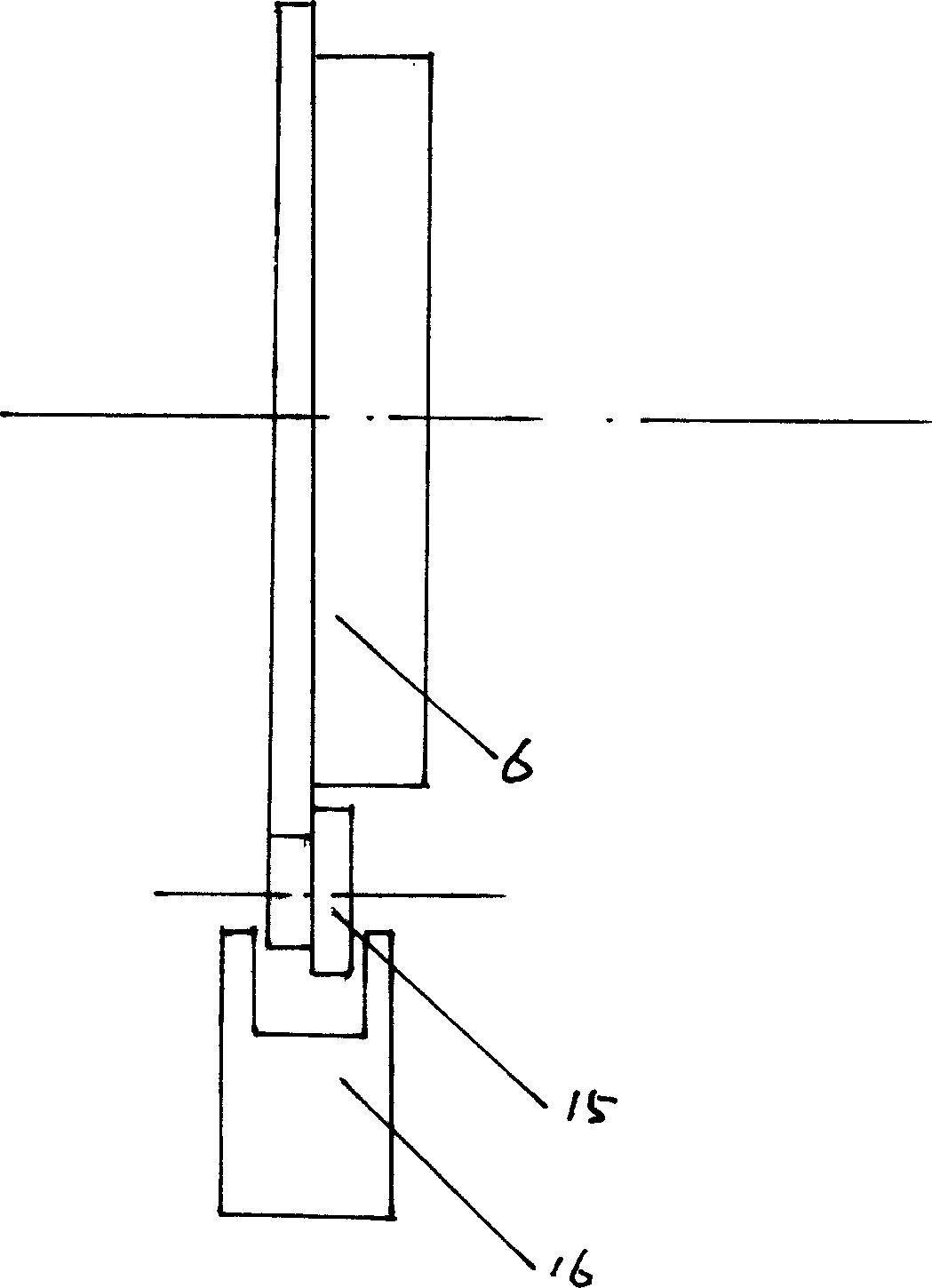

[0006] attached figure 2 It is a structural schematic diagram of Embodiment 2 of the present invention.

[0007] In the figure, 1 compressor casing, 2 compressor impeller, 3 compressor impeller shaft, 4 diffuser plate, 5 support body, 6 internal combustion engine flywheel, 7 internal combustion engine body, 8 friction wheel, 9 roller, 10 bearing, 11 tie rod, 12 Support shaft, 13 springs, 14 supports, 15 tower wheels, 16 shift forks.

[0008] In the figure, the compressor impeller 2, the friction wheel 8 and the compressor impeller shaft 3 are fixedly assembled into one structure, the friction wheel 8 is connected with the flywheel 6 of the internal combustion engine in a friction transmission mode, and the bracket 14 and the support body 5 in the compressor are flexibly connected by the bracket shaft 12 A spring 13 is installed between the bracket 14 and the support body 5, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com