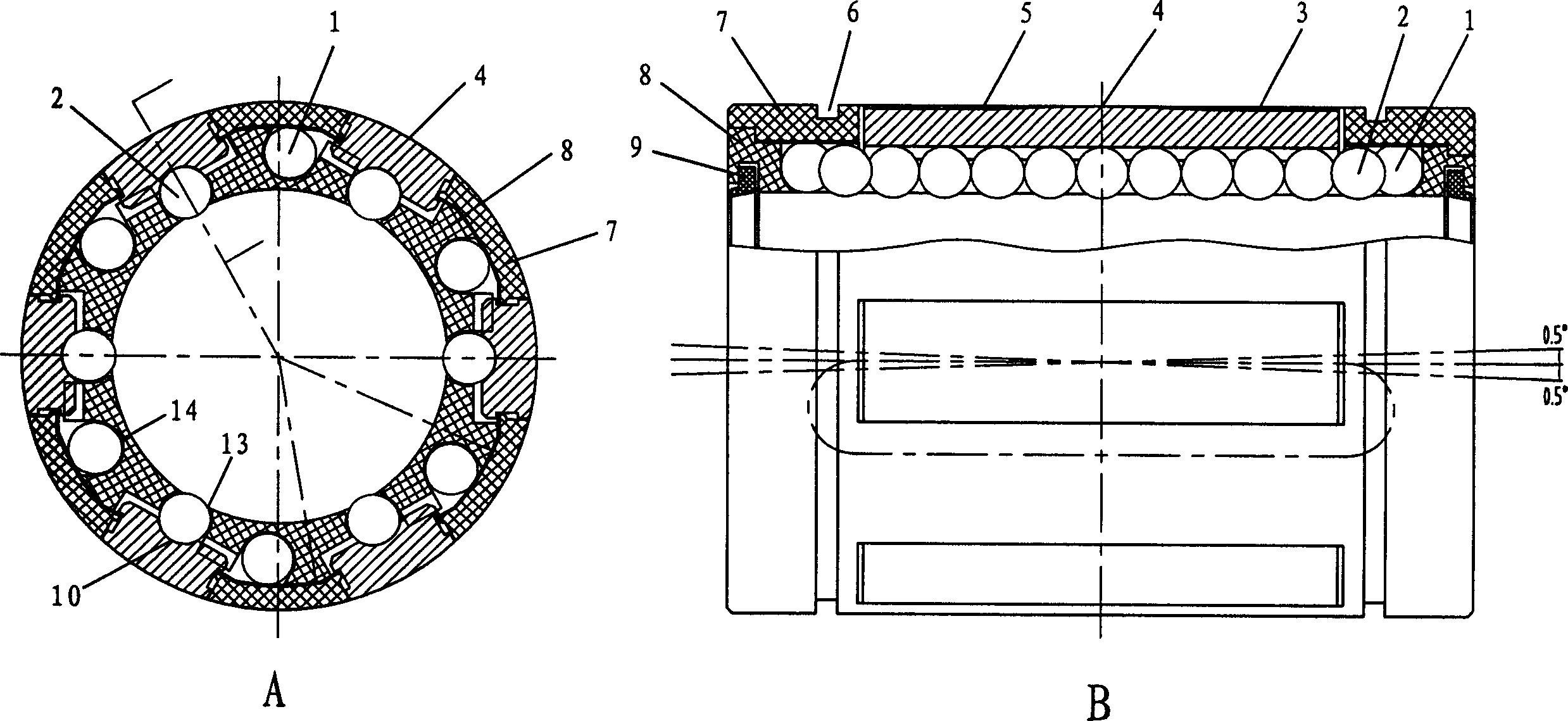

Self-regulating straight line bearing and machining method thereof

A technology of linear bearing and processing method, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems of difficult quality control of parts, large material consumption, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

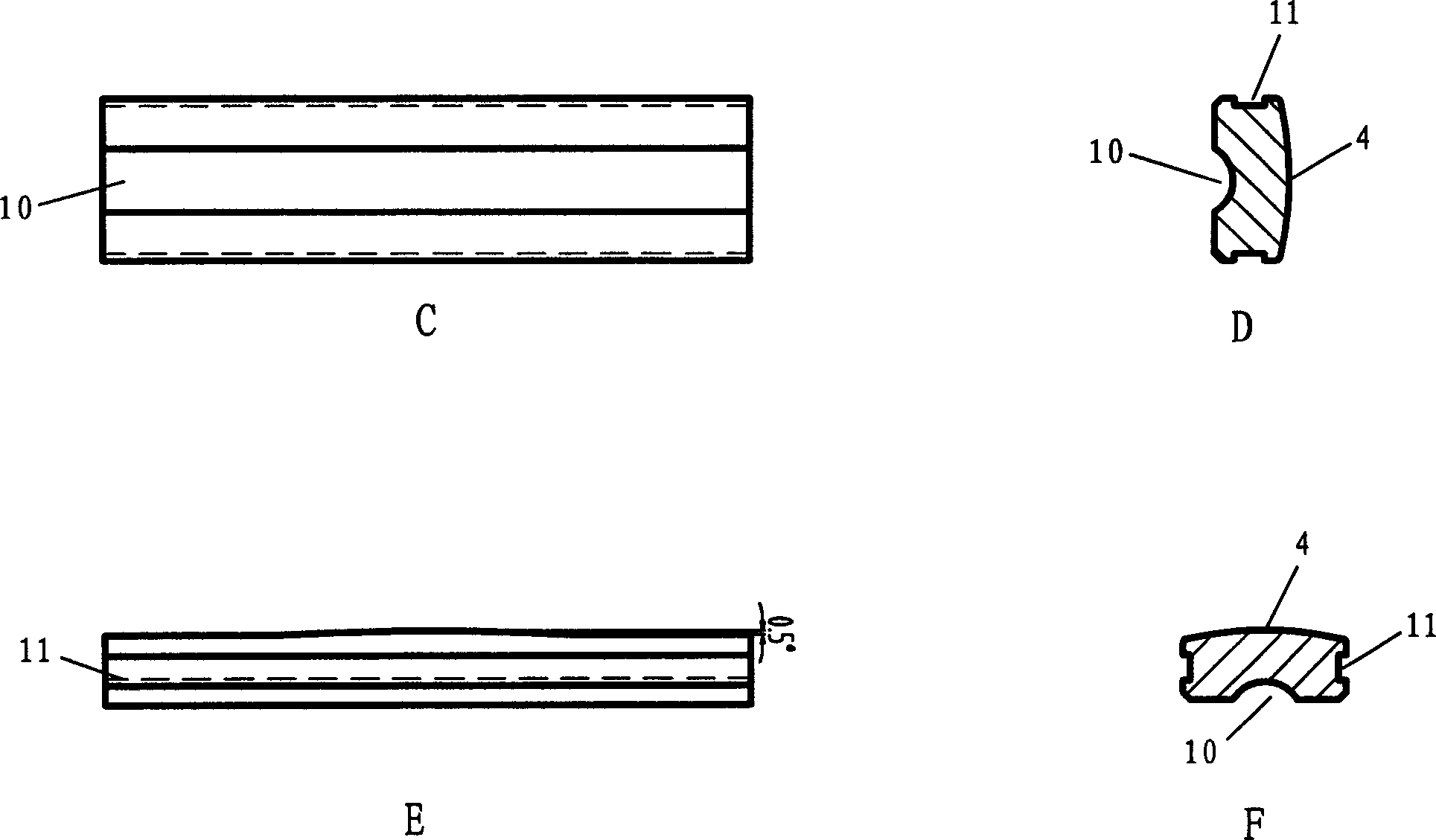

[0017] A manufacturing method of a plastic shell and a plastic cage.

[0018] High-quality polyoxymethylene resin is the first choice for the raw material of the plastic shell and plastic cage, because the hardness and strength of polyoxymethylene are higher than other engineering plastics, and the price is moderate. It has little shrinkage and deformation during injection molding and is easy to injection mold. After adding a small amount of additive and lubricant in the injection molding process, the wear resistance and lubrication performance are improved, and it is more suitable for making bearing plastic shells and cages.

[0019] The molds for making plastic shells and plastic cages, such as cavity and core materials, use 3Gr2W8V alloy mold steel with high strength, surface wear resistance, corrosion resistance, and small quenching deformation. After the cavity and the core are made, they are heat treated by quenching and tempering at medium temperature to make them have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com