Combustion-supporting dust remover for coal-fired boiler

A technology for coal-fired boilers and dust collectors, which is applied in the field of boiler dust removal, can solve problems such as incomplete combustion of coal, achieve significant energy-saving effects, improve fullness, and reduce eddy current areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

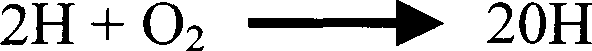

[0008] Well known; do not use mixed gas (H 2 O, O 2 ) combustion, the reaction of fixed carbon combustion is

[0009]

[0010]

[0011]

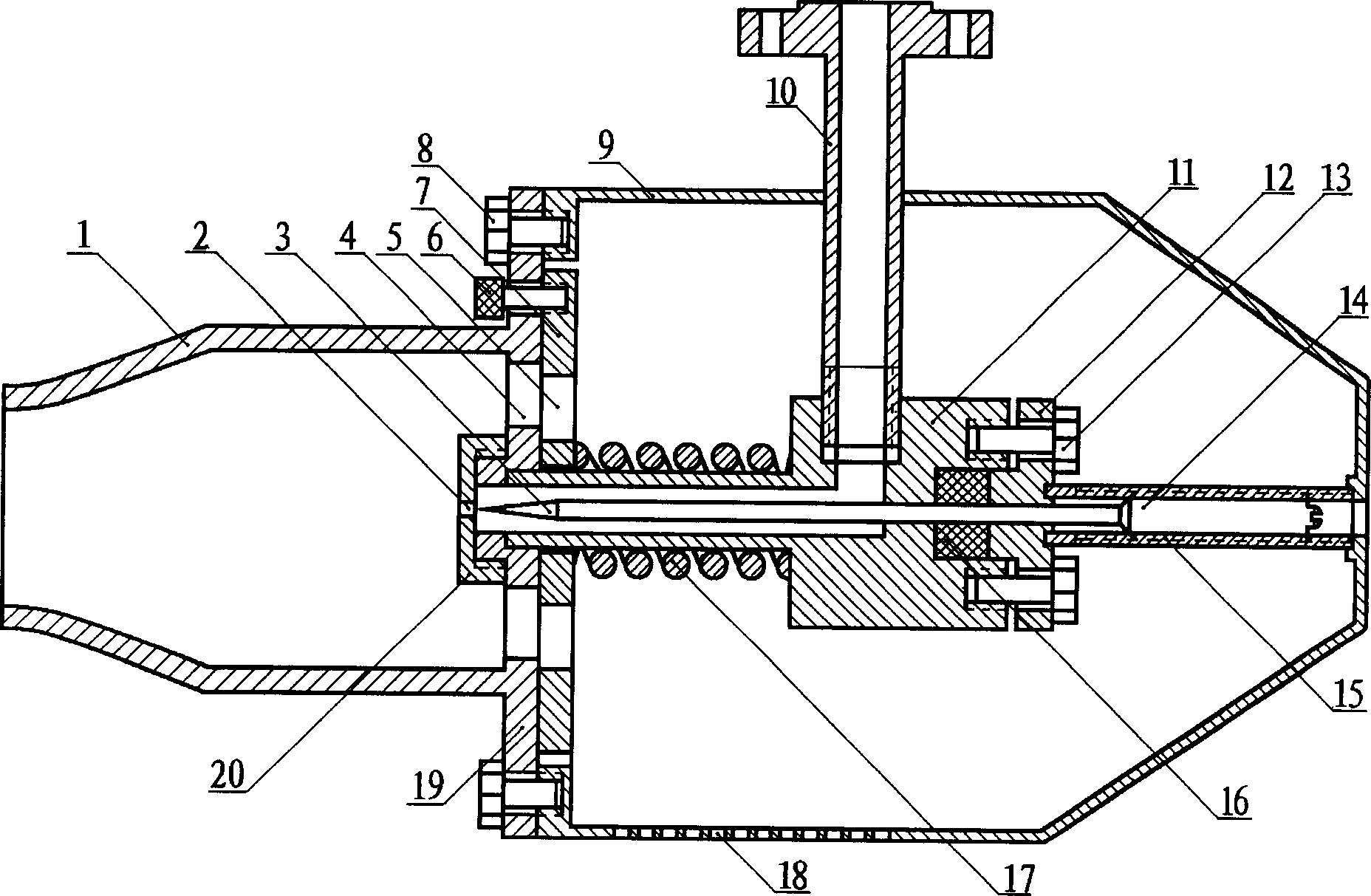

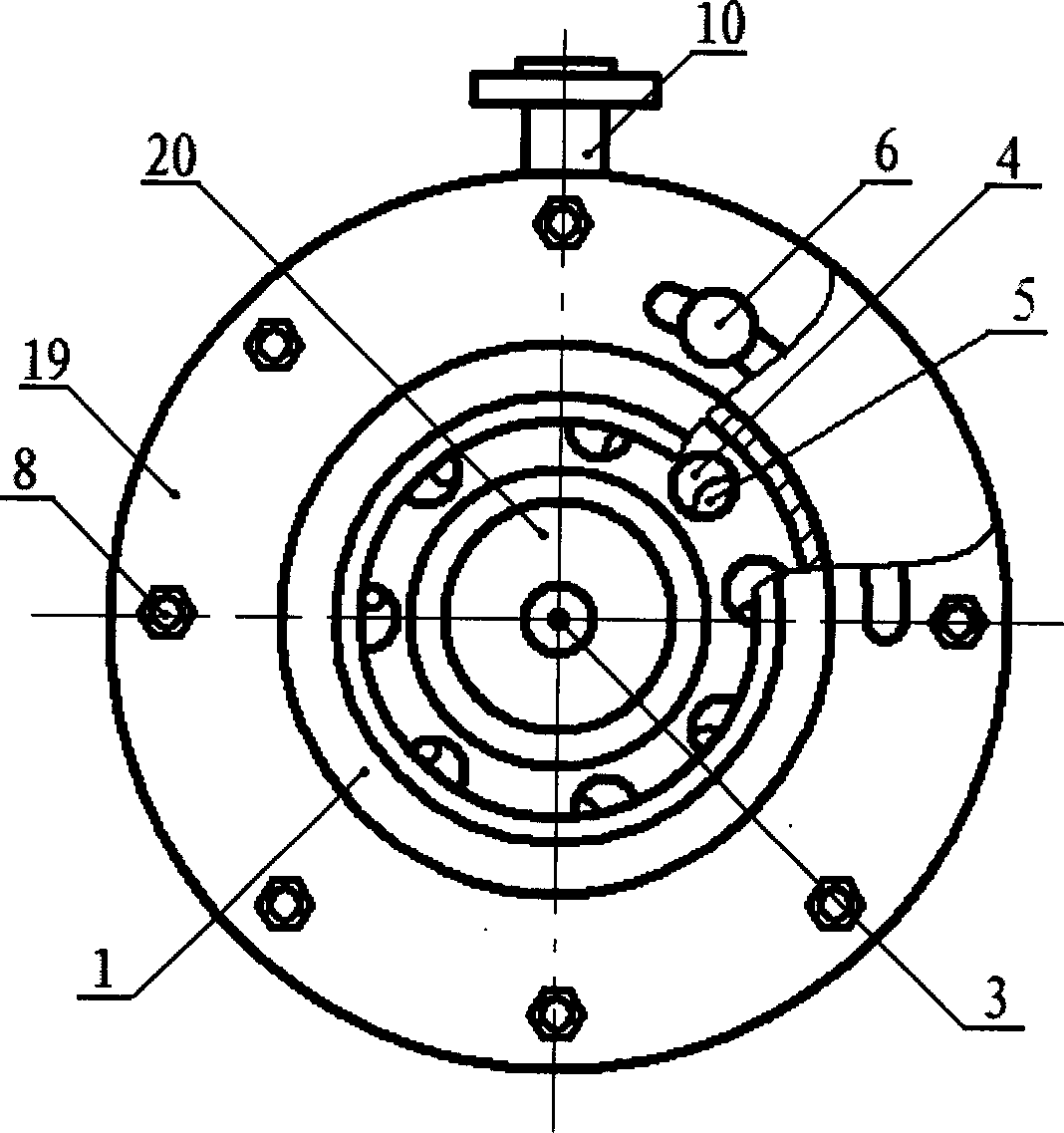

[0012] The invention is designed according to the principle of thermodynamic balance of coal combustion. Use a small amount of steam and air to convert it into a mixed gas with a certain temperature (H 2 O, O 2 ) is injected into the furnace, a negative pressure area is formed at the injection port, and the CO and C particles in the heat-absorbing area (130-400°C) and the flue gas (CO in the heat-generating area (600-700°C) 2 , CO, etc.) supplement this area to form a vortex flow, prolong the residence time in the main combustion area, and promote the C particles in the heat-absorbing area and the CO in the exothermic area to be further heated. At this time, the hot carbon captures oxygen, and then generates Activated Hydrogen (H)

[0013]

[0014] When the mixed gas is continuously injected into the furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com