Online resistance-capacitance type method and apparatus for analyzing water content in high temperature smoke

A high-temperature flue gas and moisture meter technology, applied in the direction of material impedance, sampling device, material resistance, etc., can solve the problems of flue gas dust wear and blockage, and achieve the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

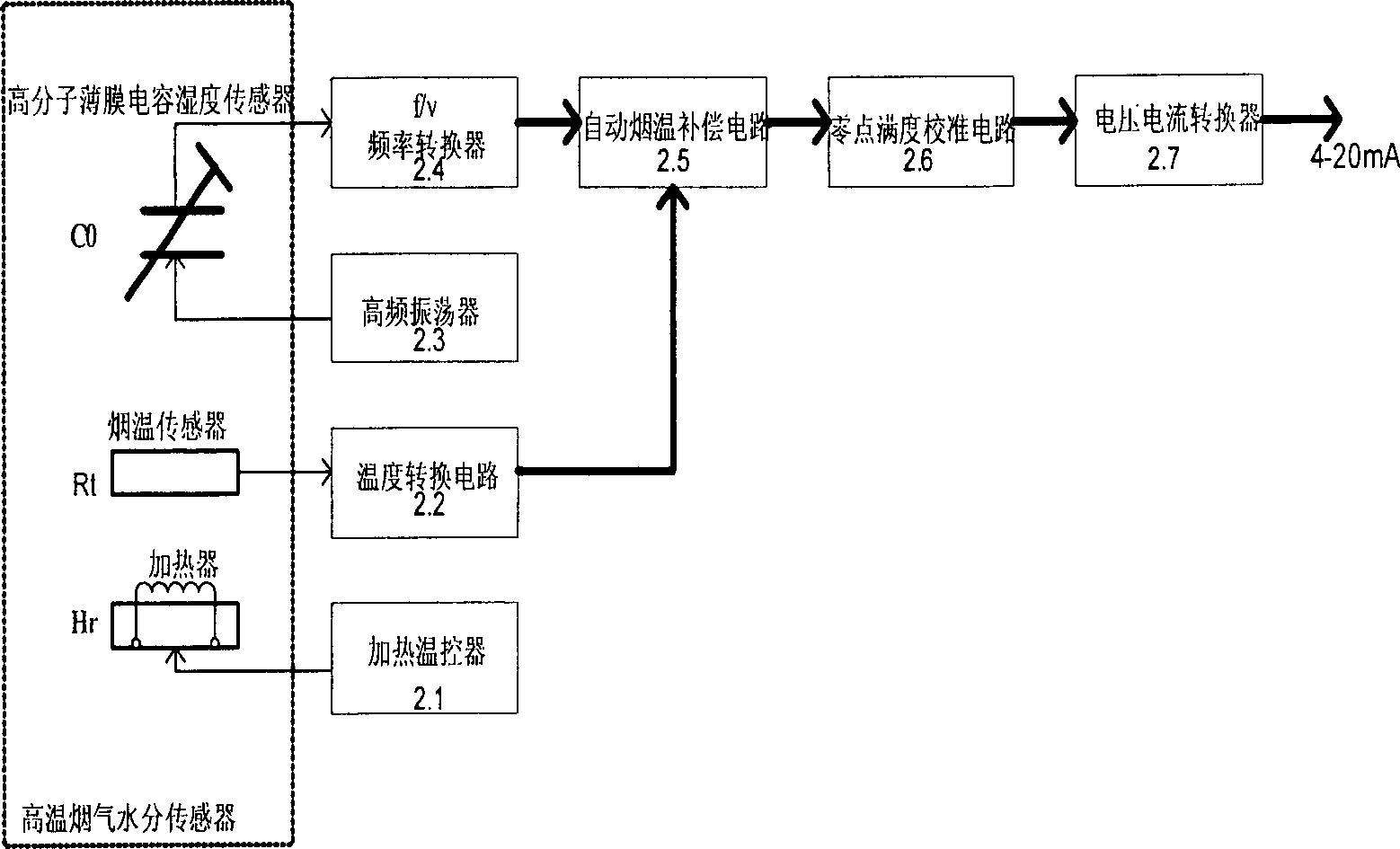

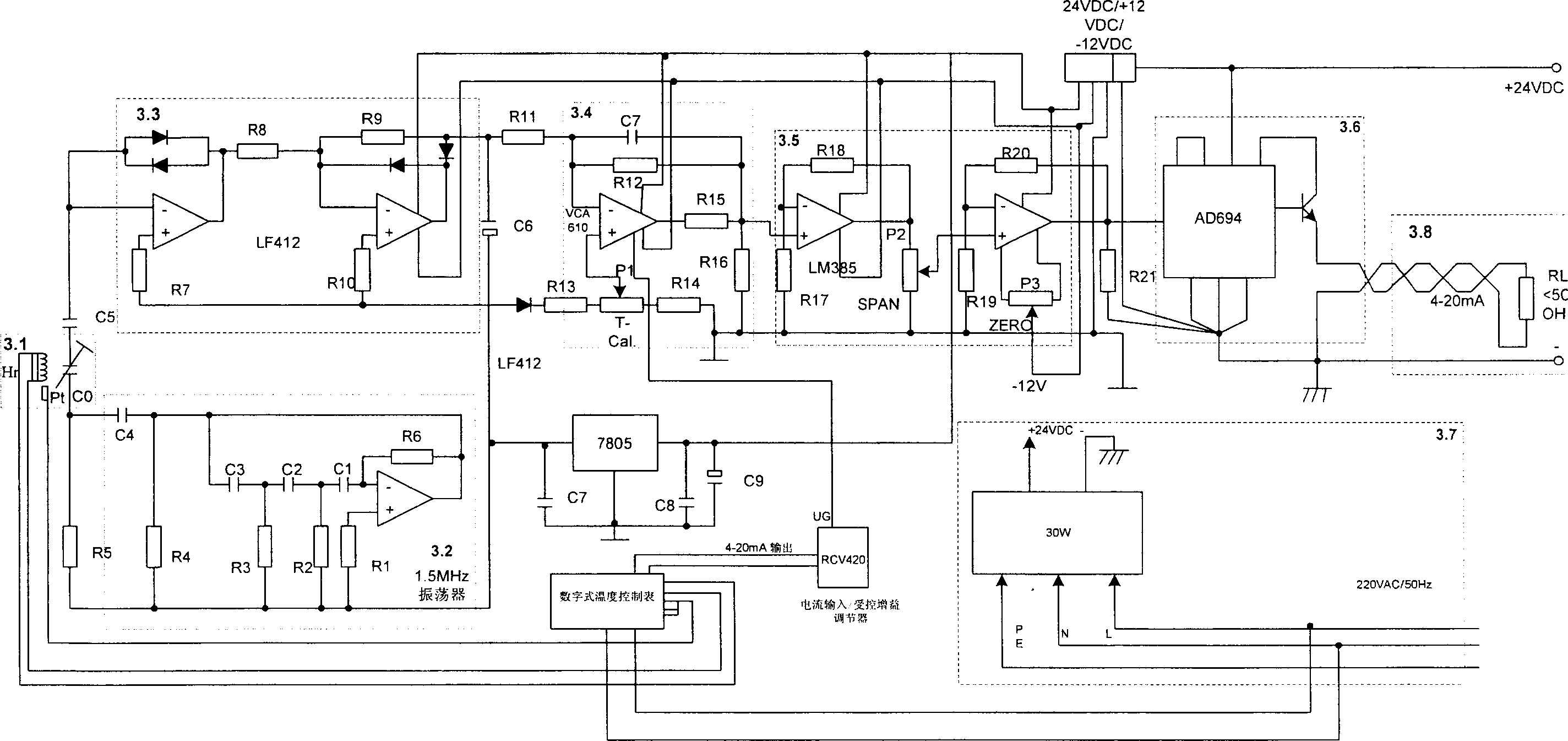

[0030] The principle and implementation method of the online resistance-capacitance high-temperature flue gas moisture meter will be described in detail below in conjunction with the attached drawings:

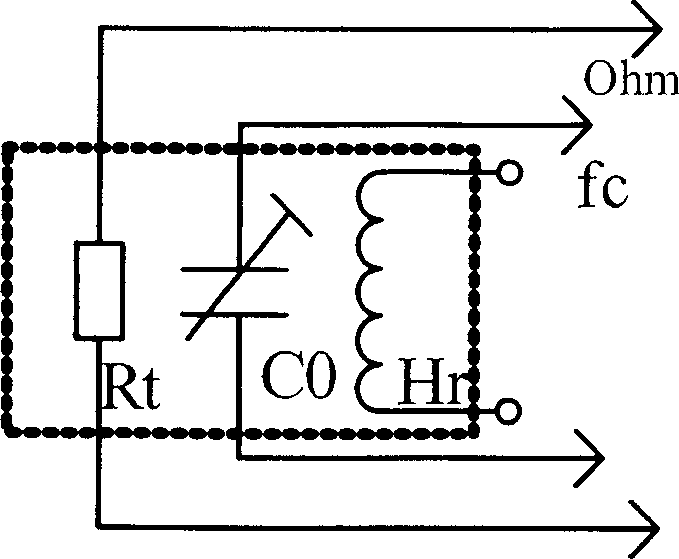

[0031] 1) The resistance-capacitance sensor includes a polymer film capacitive humidity sensitive element ( figure 1 C0 in), used to measure the moisture change in the high temperature flue gas;

[0032] 2) Pt100 platinum resistance smoke temperature sensor ( figure 1 Rt in ) is used to measure flue gas temperature change of high-temperature flue gas, and is used for temperature compensation of flue gas moisture measurement;

[0033] 3) Heater ( figure 1 Hr in), used to heat the polymer film capacitance humidity sensitive element ( figure 1 C0) in the flue gas to prevent moisture condensation in the flue gas from corroding and damaging the humidity sensitive element of the polymer film capacitor ( figure 1 C0 in ),

[0034] 4) The above three together constitute the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com