Method for preparing pseudoboehmite

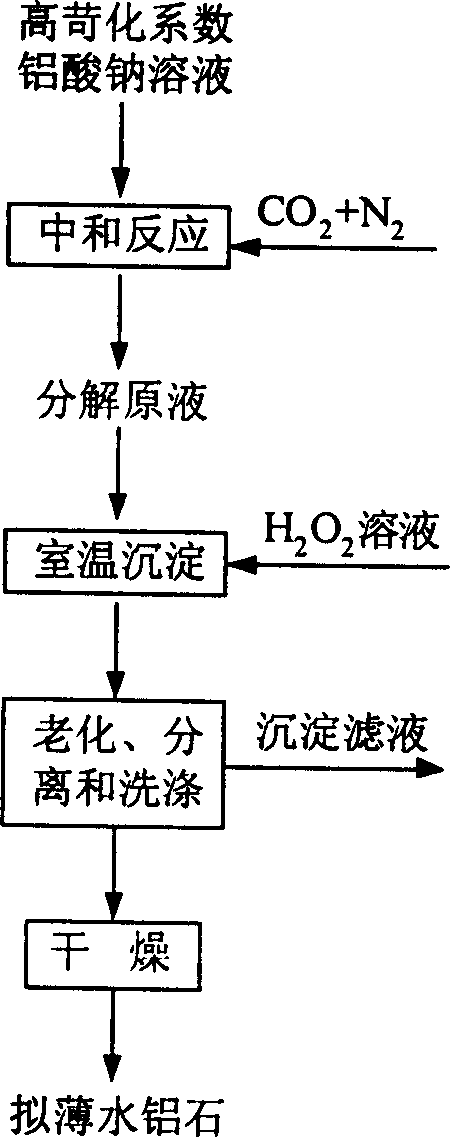

A technology of pseudo-boehmite and sodium aluminate, which is applied in the production process of chemical alumina, can solve the problems of low precipitation rate and high causticization coefficient, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

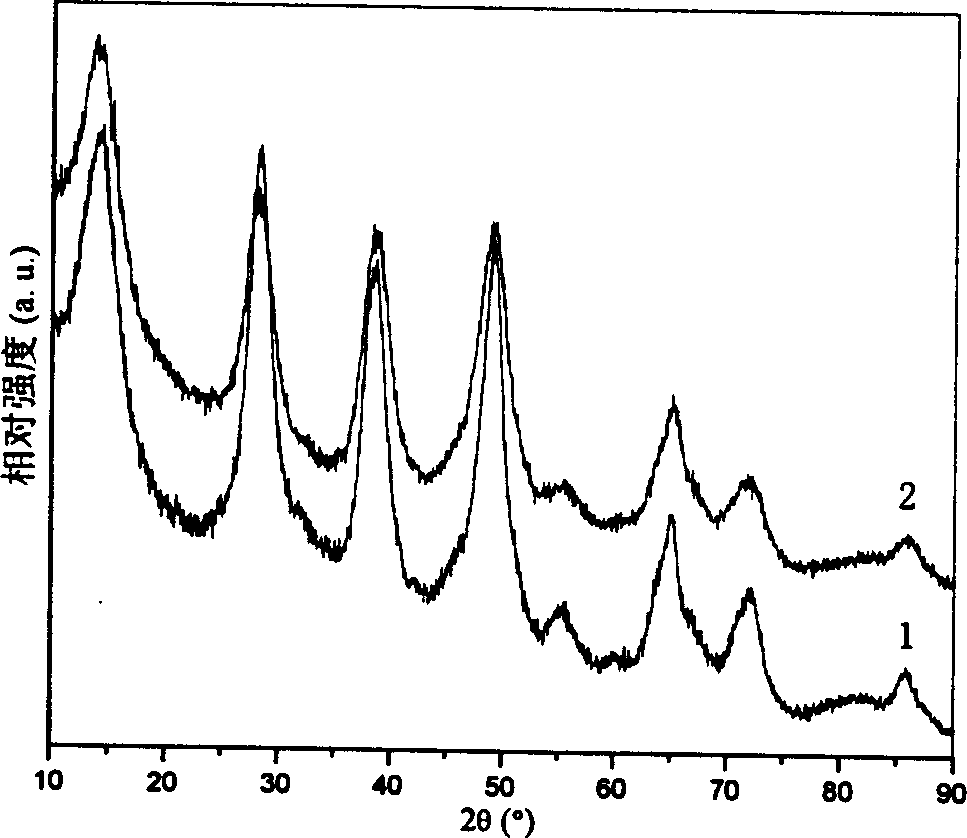

Embodiment 1

[0019] At 0°C, the mechanical stirring speed is 380r·min -1 Downward volume is 160ml, Al 2 o 3 The content is 50.00g·L -1 , The causticization coefficient is 3.5 (106.37g L -1 -Na 2 O) Slowly introduce CO into the sodium aluminate solution 2 35.0v% CO 2 and N 2 The mixed gas, the mixed gas flow rate is 30L·L -1 溶液 h -1 , after ventilation for 76min, the concentration of sodium hydroxide in the solution decreased to 39.51g·L - 1-Na 2 O, sodium carbonate concentration 66.86g L -1 -Na 2 O, the causticization coefficient dropped to 1.3. Subsequently, 56mL, 30.0wt% H 2 o 2 solution, H 2 o 2 / Al 2 o3 =7.0:1.0 (molar ratio), the feeding rate is 1.80ml / min. The filtrate was analyzed by ICP-AES and the precipitate Al was precipitated from the sodium aluminate solution 2 o 3 The precipitation rate is 99.3%. After aging the precipitate for 30 minutes, vacuum filter it, wash it with 30°C water until the filtrate is neutral, and dry the filter cake at 80°C to obtain th...

Embodiment 2

[0023] At 18°C, the mechanical stirring speed is 380r·min -1 Down, to a volume of 160ml, Al 2 o 3 The content is 100.00g·L -1 , The causticization coefficient is 3.0 (182.35g L -1 -Na 2 O) Slowly introduce CO into the sodium aluminate solution 2 37.0v% CO 2 and N 2 The mixed gas, the mixed gas flow rate is 45L·L -1 溶液 h -1 , after aeration for 104min, the concentration of sodium hydroxide in the solution decreased to 97.25g·L -1 -Na 2 O, the concentration of sodium carbonate is 85.10g L -1 -Na 2 O, the causticization coefficient decreased to 1.6. Subsequently, inject 257.9mL, 10.0wt% H 2 o 2 solution, H 2 o 2 / Al 2 o 3 =5.0:1.0 (molar ratio), the feed rate is 8.28ml min -1 . Analyze the filtrate with a single-channel scanning inductively coupled plasma emission spectrometer (ICP-AES, the same below), and precipitate Al from the sodium aluminate solution 2 o 3 The precipitation rate was 95.4%. After aging the precipitation for 30 minutes, it was vacuum fi...

Embodiment 3

[0027] At 30°C, mechanical stirring speed 380r·min -1 Downward volume is 160ml, Al 2 o 3 The content is 250.00g·L -1 , The causticization coefficient is 2.0 (303.92g L -1 -Na 2 O) Slowly introduce CO into the sodium aluminate solution 2 40.0% CO content 2 and N 2 The mixed gas, the mixed gas flow rate is 60L·L -1 溶液 h -1 , after ventilation for 37.4min, the concentration of sodium hydroxide in the solution decreased to 227.94g·L -1 -Na 2 O, sodium carbonate concentration 75.98g L -1 -Na 2 O, the causticization coefficient is reduced to 1.5. Subsequently, inject 253.3mL, 15.0wt% H 2 o 2 solution, H 2 o 2 / Al 2 o 3 =3.0:1.0 (molar ratio), the feed rate is 8.15ml min -1 . Analyze the filtrate with a single-channel scanning inductively coupled plasma emission spectrometer (ICP-AES, the same below), and precipitate Al from the sodium aluminate solution 2 o 3 The precipitation rate of the precipitate was 71.0%. After aging the precipitate for 30 minutes, it wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com