Exhaust gas after-treatment unit with countercurrent housing and corresponding process for exhaust gas after-treatment

A technology of exhaust gas post-treatment and equipment, applied in exhaust gas treatment, mechanical equipment, gas passages, etc., can solve problems such as limited space and large heat load of catalytic converters, and achieve the purpose of improving service life, avoiding thermal gradients, and uniform heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

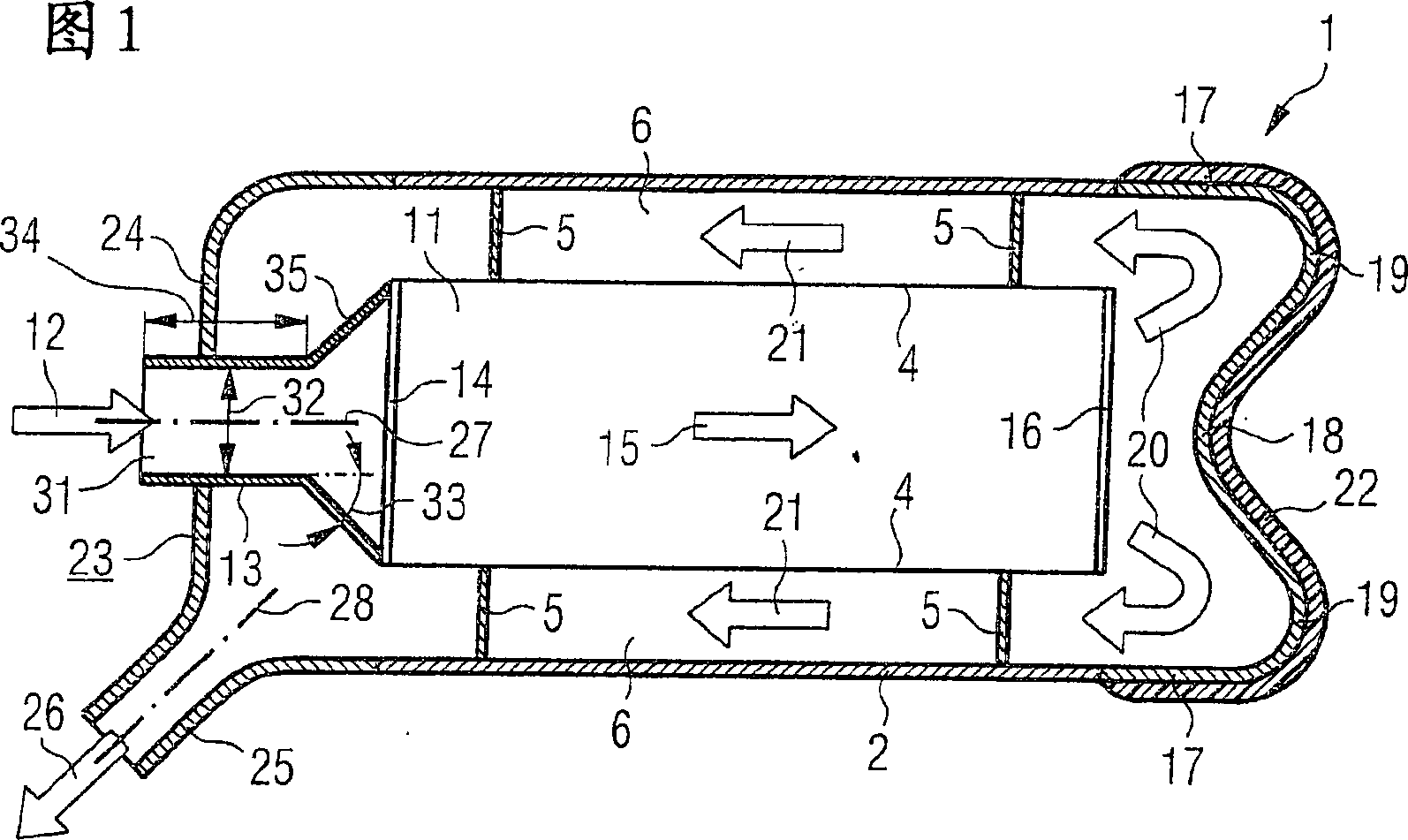

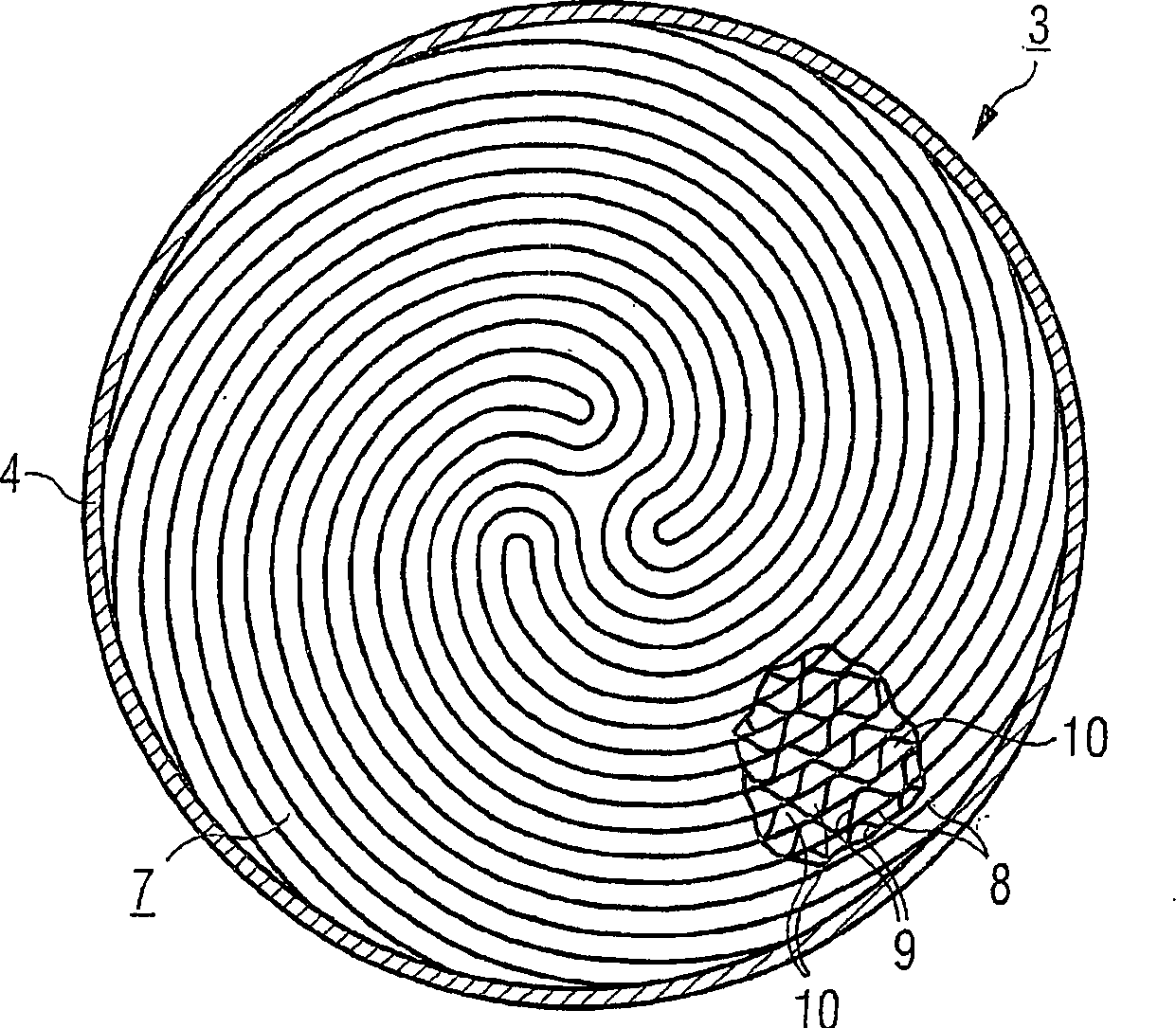

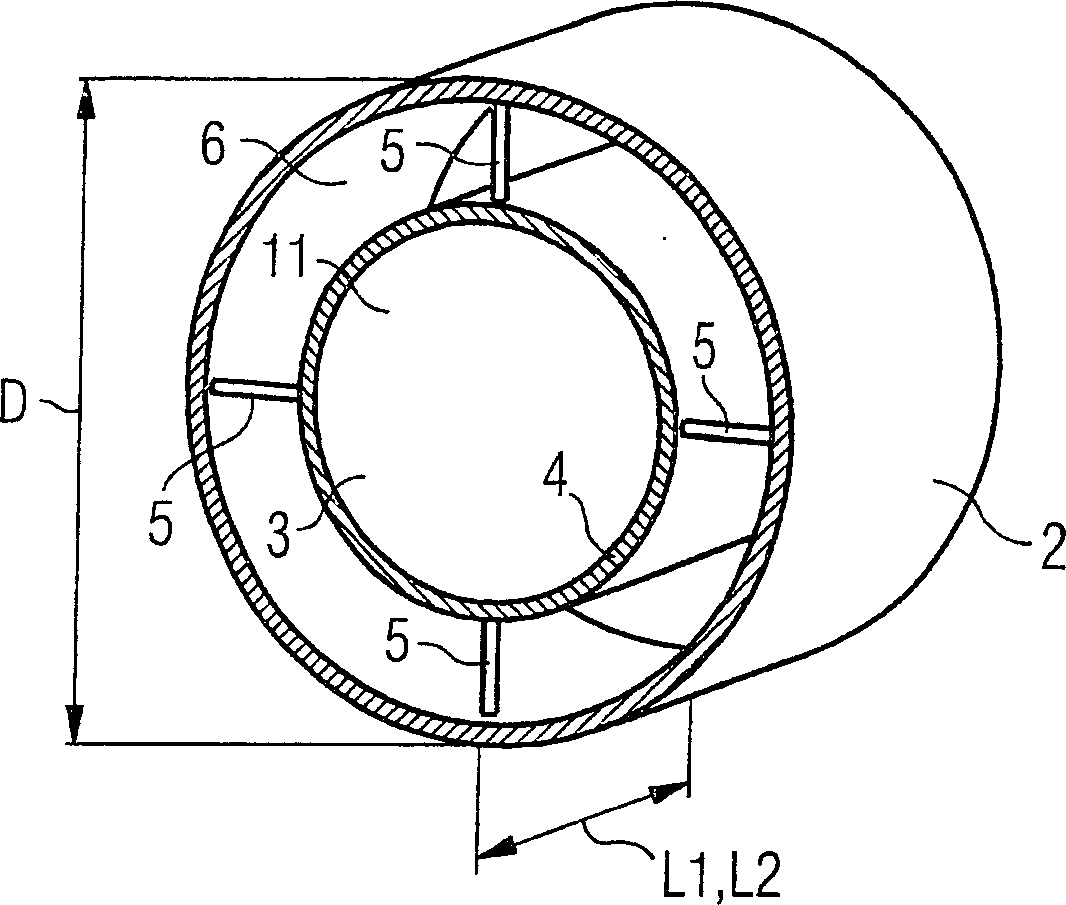

[0039] FIG. 1 schematically shows a longitudinal section through a first exemplary embodiment of an exhaust gas aftertreatment device 1 according to the invention. The exhaust gas aftertreatment device 1 has a housing 2 with a honeycomb body 3 which serves as a catalytic converter. The honeycomb body 3 is surrounded by a sleeve 4 and fastened in the housing 2 by fastening means 5 . The fastening device 5 is preferably designed as a web which does not significantly reduce the freely permeable cross-section of the recirculation zone 6 . A free-flowing cross-section means in particular that no honeycomb structures are formed in the recirculation zone. The honeycomb body 3 can be designed both as a ceramic and as a metallic honeycomb body 3 . figure 2 An example of a metal honeycomb is shown. The inlet pipe 13 is provided with a conical section 35 which directs the exhaust gas directly to the first end side 14 of the honeycomb body 3 . The cone 35 has an opening angle of at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com