Apparatus for monitoring fluid sample produced under low temperature and method thereof

A monitoring device and a technology for preparing fluids are used in the preparation of test samples, measuring devices, and material analysis by optical means, to achieve the effect of safely and reliably adjusting the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

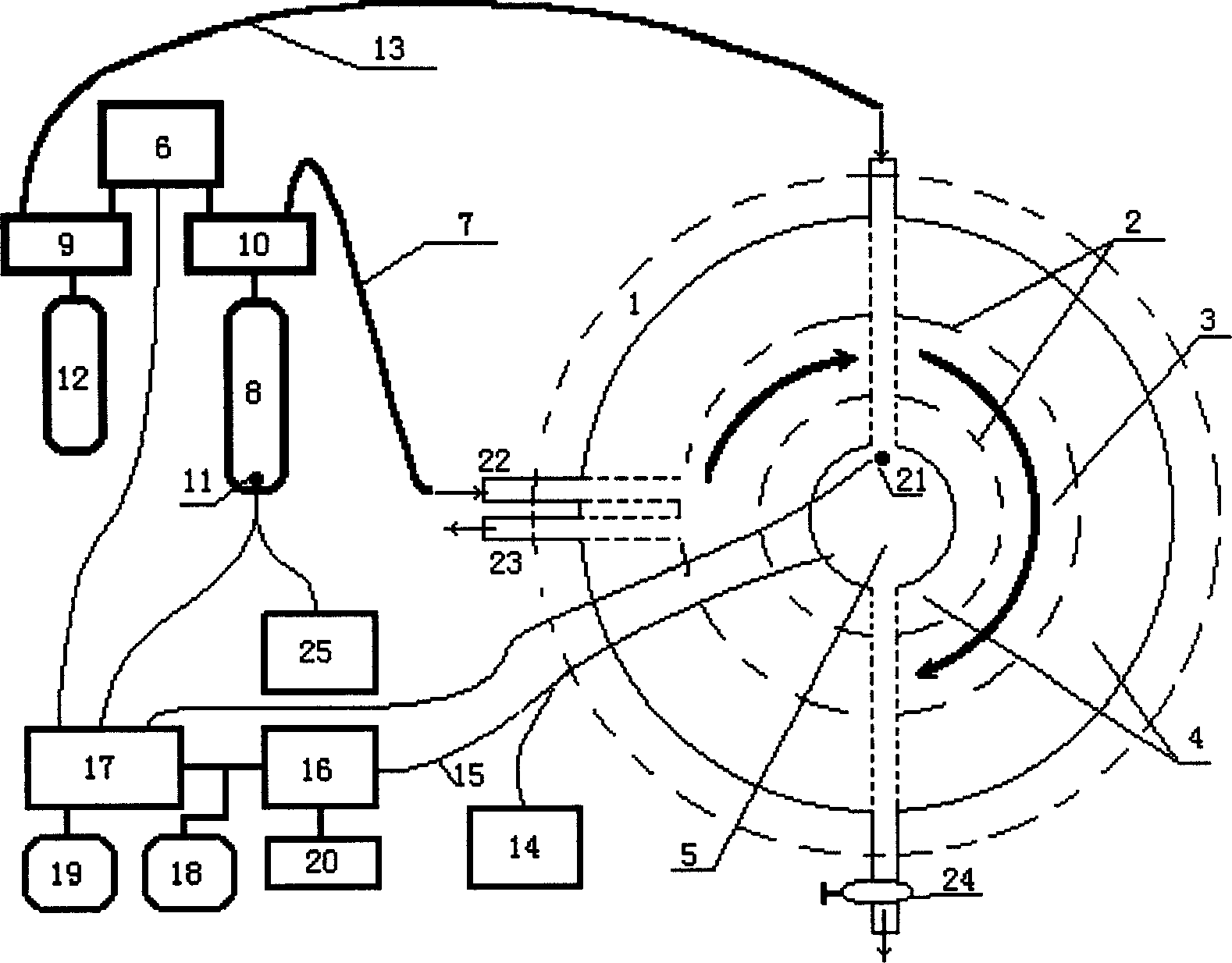

[0044] The CO high-purity liquid sample is prepared by using the monitoring device of the present invention. according to figure 1 Connect the components in the middle structure, check the conduction status of the entire device, and detect the leakage of the low-temperature pipeline. Avoid leakage and operate in a well-ventilated environment. Fill 20 liters of liquid nitrogen in the liquid nitrogen container 8, the light source 14 used is an incandescent lamp, and the first temperature sensor 21 uses a copper-constantan thermocouple. The specific operation steps are:

[0045] 1. Open flushing valve 24, use 2kg / cm 2 The sample chamber 5 is purged with CO sample gas to ensure that the residual gas sample does not affect the purity of the sample preparation;

[0046] 2. Utilize the first temperature sensor 21 to control the heater 11 to heat the liquid nitrogen in the liquid nitrogen container 8, so that the liquid nitrogen in the liquid nitrogen container is not greater than ...

Embodiment 2

[0051] Use the monitoring device of the present invention to prepare CO+N 2 High-purity mixed liquid samples. The experimental equipment and experimental environment used are the same as those in the first embodiment, but the process is slightly different. The second temperature sensor 26 also uses a copper-constantan thermocouple.

[0052] Wherein step 1-3 is identical with embodiment one, guarantees to mix sample CO+N in liquefaction 2 In order to ensure the safe operation of the system and the accuracy of cooling control during the process, perform the following operations:

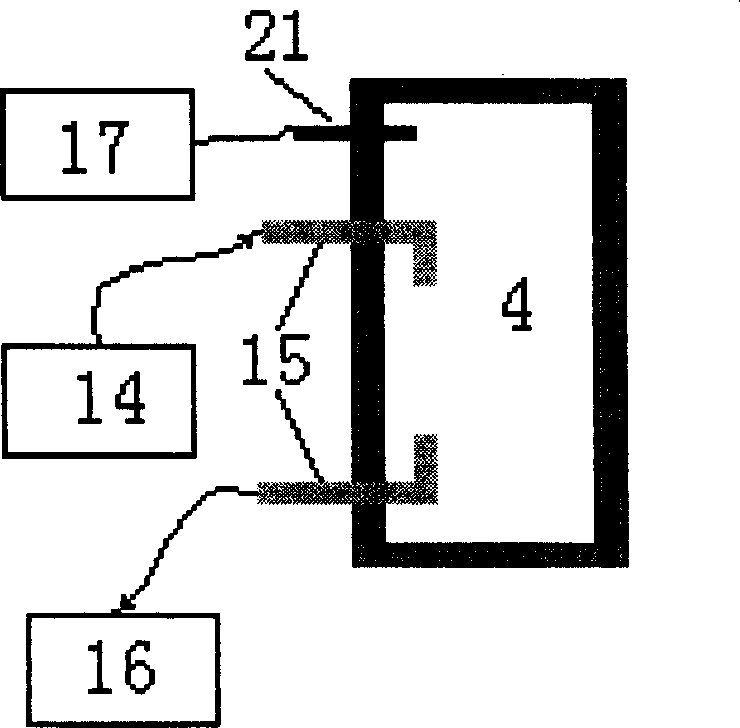

[0053] a. First use 1.4×10 5 N of Pa 2 Fill the cryogenic sample chamber 5, when the liquefied N 2 When the indication value of the second temperature sensor 26 placed on the radius height of the front panel of the optical fiber sensor changes suddenly, it indicates that the sample liquid nitrogen has filled 1 / 2 of the sample chamber volume, and at this time, the CO gas sample tank 12 is replaced w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com