Detecting instrument for concrete gas seepage coefficient under single-shaft-pressure stress and detecting method

A uniaxial compressive stress and gas permeation technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of cumbersome test experiments, complicated test procedures, and laborious loading and unloading, and achieve reliable test results, easy operation, and portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

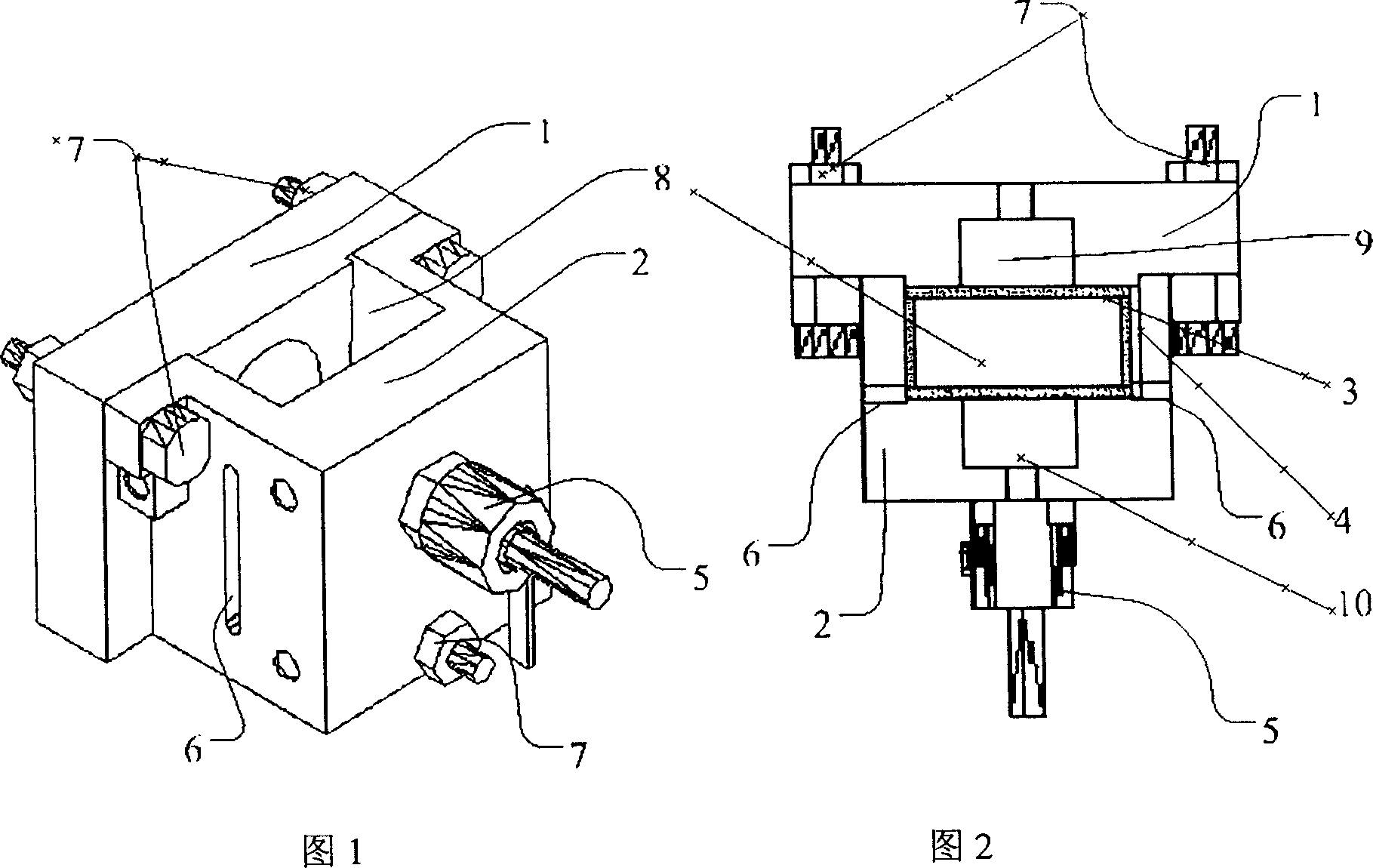

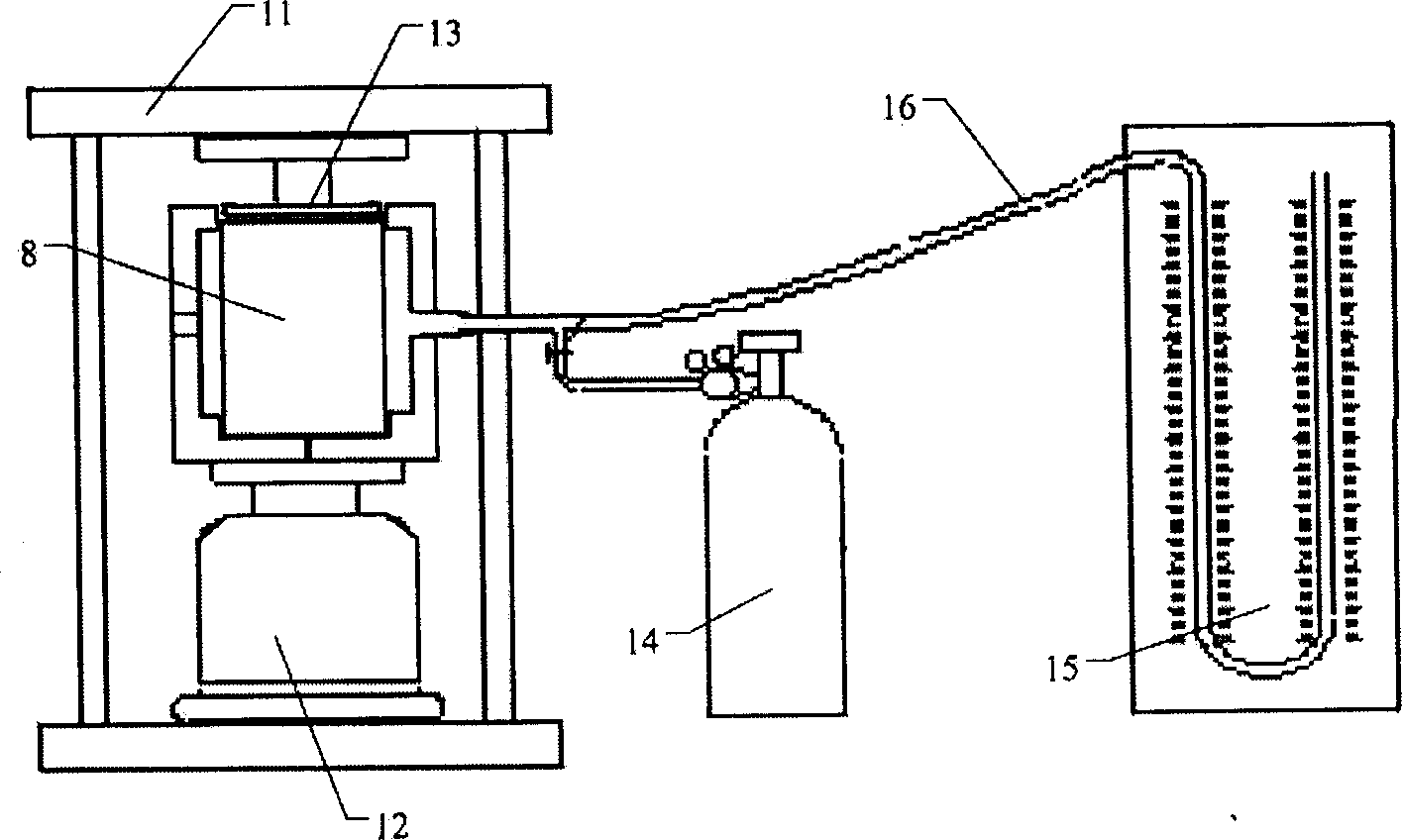

[0038] Embodiment 1: The following components are connected in the manner shown in Figures 1 and 2, and those skilled in the art can implement it smoothly. The mold cover plate 1 is made of A3 steel material, and its size is 130 mm in length, 90 mm in width, and 30 mm in thickness; the diameter of the air outlet chamber 9 is 50 mm, and its depth is 18 mm; The thickness is 75mm; the diameter of the air inlet chamber 10 is 50mm, and the depth is 18mm; the width of the sealing inspection groove 6 is 4mm, and the length is 70mm; the size of the concrete sample to be tested is 70.7mm×70.7mm×40mm; the model of the air inlet valve 5 is DN10; The compressed gas tank 14 is an industrial nitrogen cylinder; the hose 16 is a vacuum rubber tube; the manometer 15 is a mercury U-shaped manometer; the jack 12 is an oil pressure 20t; the gasket 3 adopts a 3mm thick vacuum rubber gasket.

Embodiment 2

[0039] Embodiment 2: test method

[0040] Form the sample according to the mix ratio in Table 1. The size of the concrete sample is 70.7mm×70.7mm×40mm, and the test gas medium is nitrogen.

[0041] Dry the above-mentioned concrete samples that have reached the age of 28 days at 55±2°C, paste vacuum rubber gaskets with a thickness of 2mm on four sides along the thickness direction, and paste vacuum rubber gaskets with a thickness of 3mm on the two sides in the air-permeable direction , the adhesive can be made of silicone rubber, and all the corners of the concrete sample are sealed with thick white paint or silicone glue, and the treated sample is placed in a drying dish and allowed to stand at room temperature for 48 hours. The treated concrete sample is placed in the mold, pressed into the side pressure sealing wedge, tightened the connecting nut on the mold, and then placed the mold on the jack in the bracket, closely attached to the top plate and bottom of the bracket, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com