Semi-automatic underwater welder with local dryness

A local dry and underwater welding technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as arc instability, poor mechanical properties of welded joints, and poor weld formation, achieving low cost, Strong adaptability to operation and high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

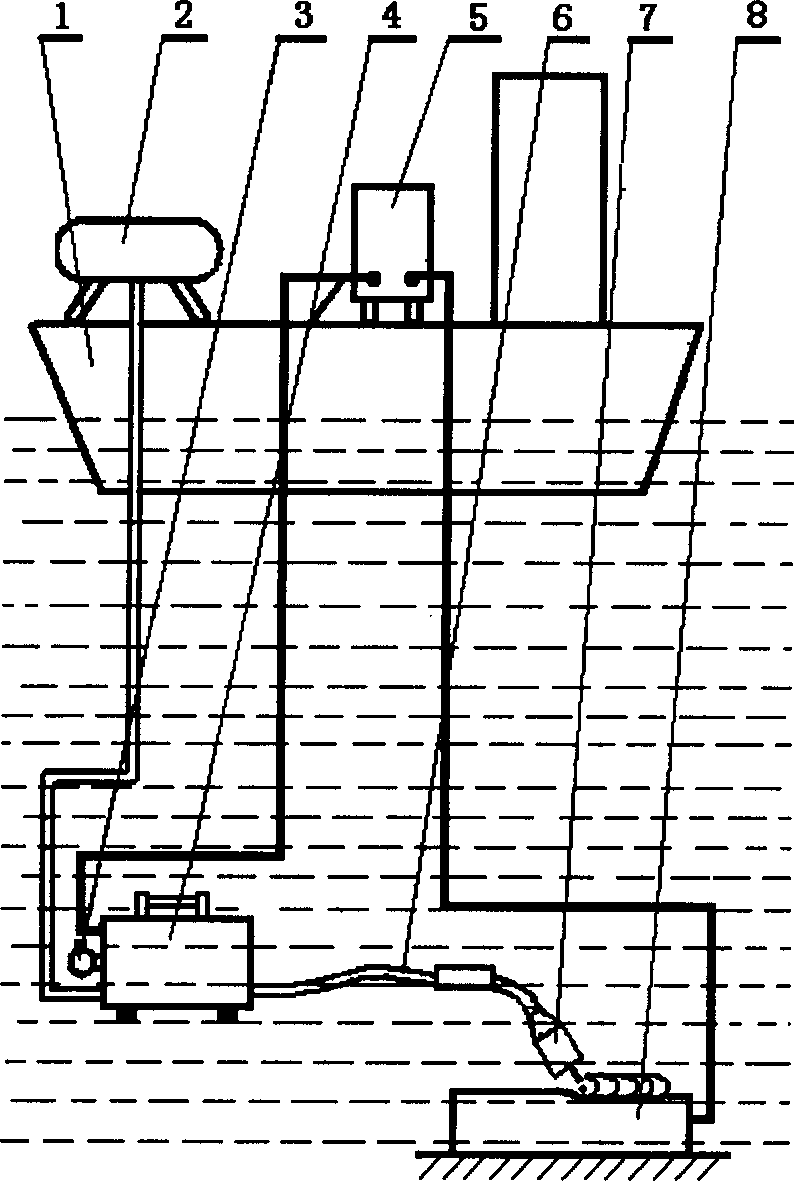

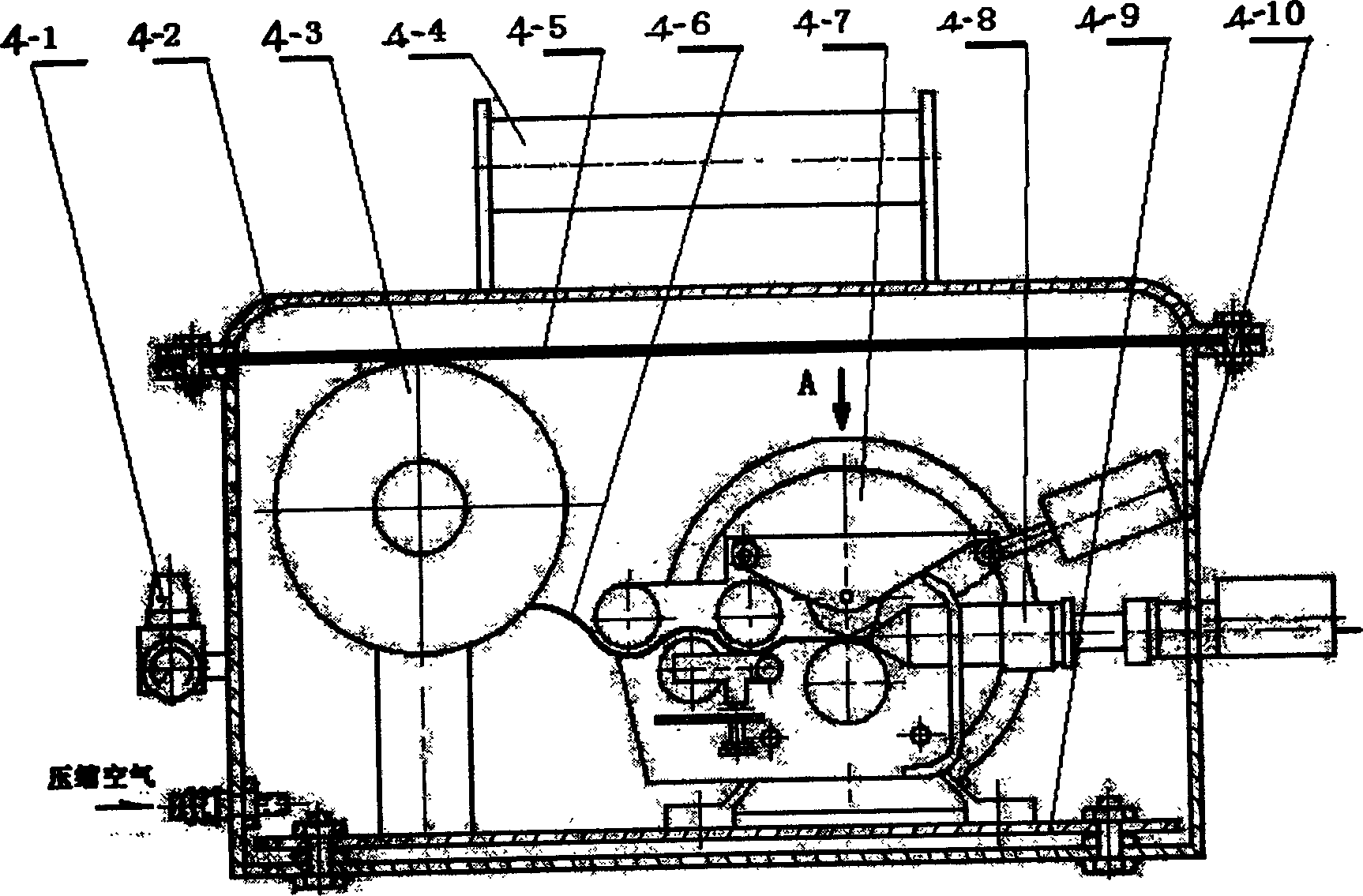

[0017] Depend on figure 1 It can be seen that in the semi-automatic partial dry underwater welding device of the present invention, the compressed air produced by the air compressor 2 communicates with the underwater wire feed box 4 through the pipeline; the special welding power supply 5 is connected with the underwater wire feed box 4 through cables; The lower wire feeding box 4 is connected with the welding torch 6 through the wire guide tube, and the miniature drainage cover 7 is installed at the end of the welding torch.

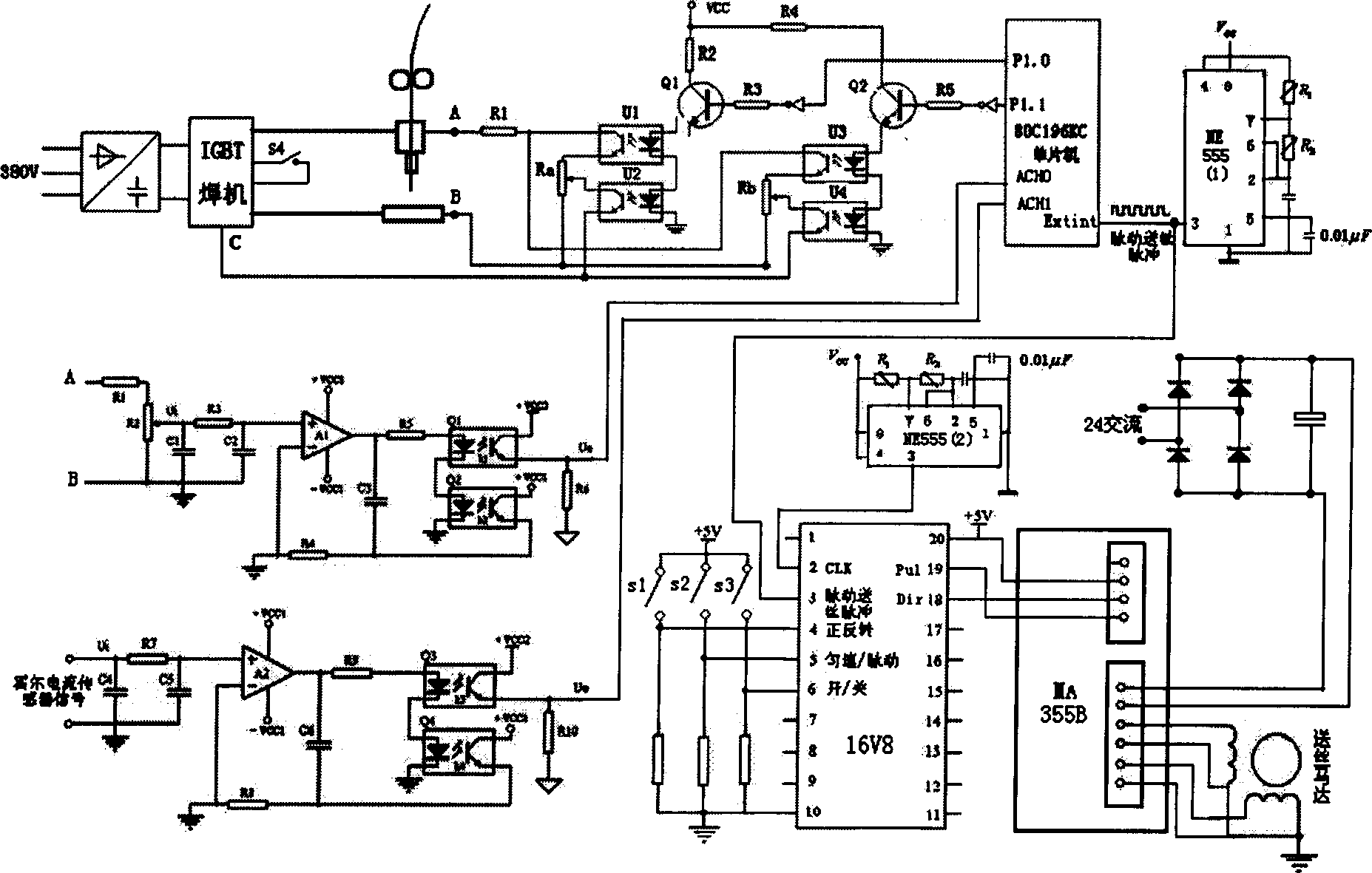

[0018] figure 2 It is a circuit diagram of a special welding power supply (including a pulsating wire feeding system) of the new semi-automatic partial dry underwater welding device of the present invention. After the system is powered on, figure 2 The NE555(2) in it generates a clock pulse with a frequency of about 10 kHz, which is used to drive the stepper motor to rotate, and the NE555(1) generates a pulsating wire-feeding pulse with a frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com