Measuring device for heat-barrier coating heat-shock resisting performance

A technology of thermal barrier coating and testing device, which is applied in the direction of measuring device, mechanical device, and application of repeated force/pulsation force to test the strength of materials, etc., which can solve the problems of increasing process and cost, and inability to perform rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

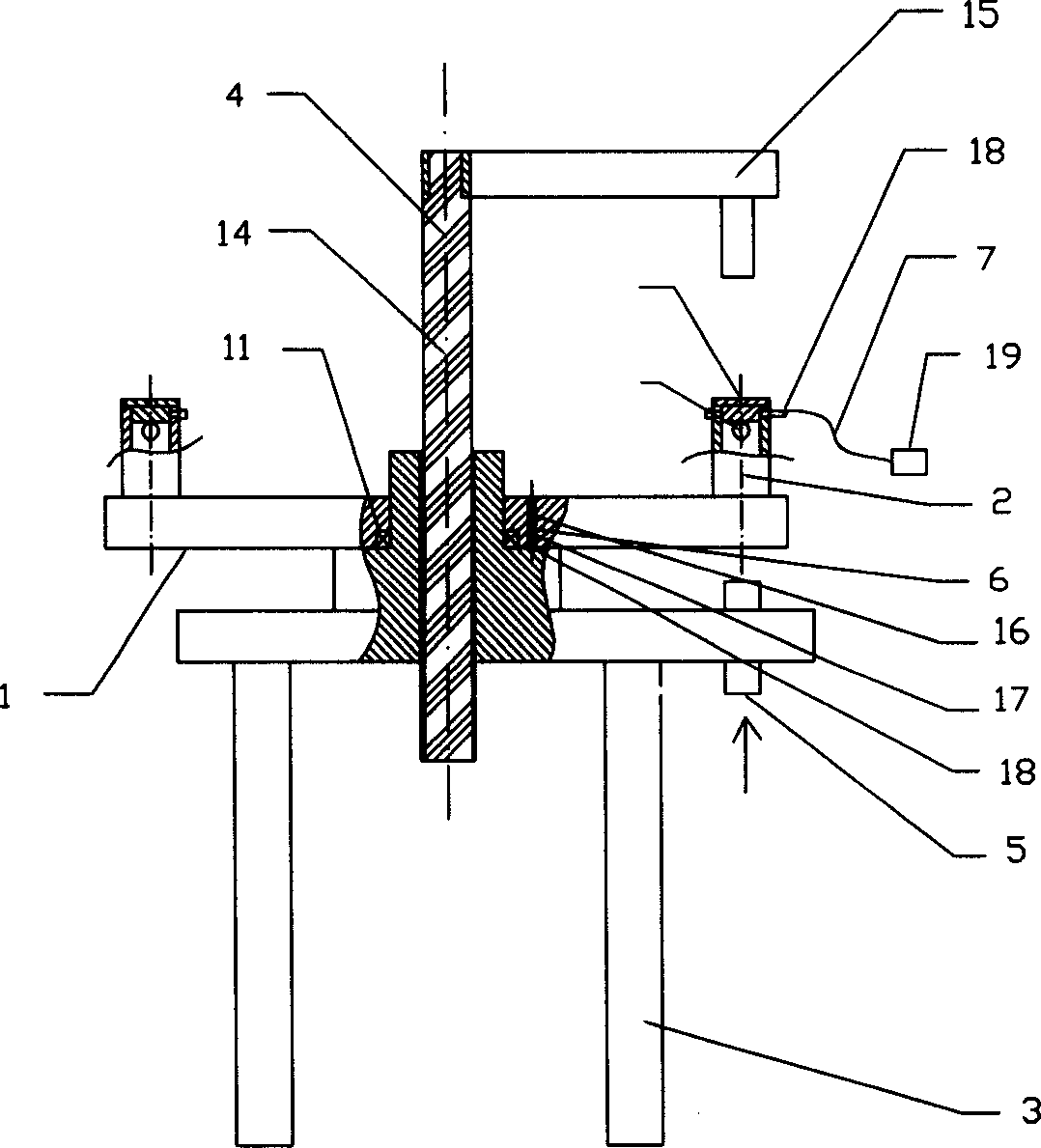

[0011] Such as figure 1 , figure 2 As shown, the present invention includes: a rotating circular platform 1 , a sample holder 2 , a workbench 3 , a heat source installation device 4 , a cooling medium input port 5 , a positioning device 6 , and a temperature measuring device 7 .

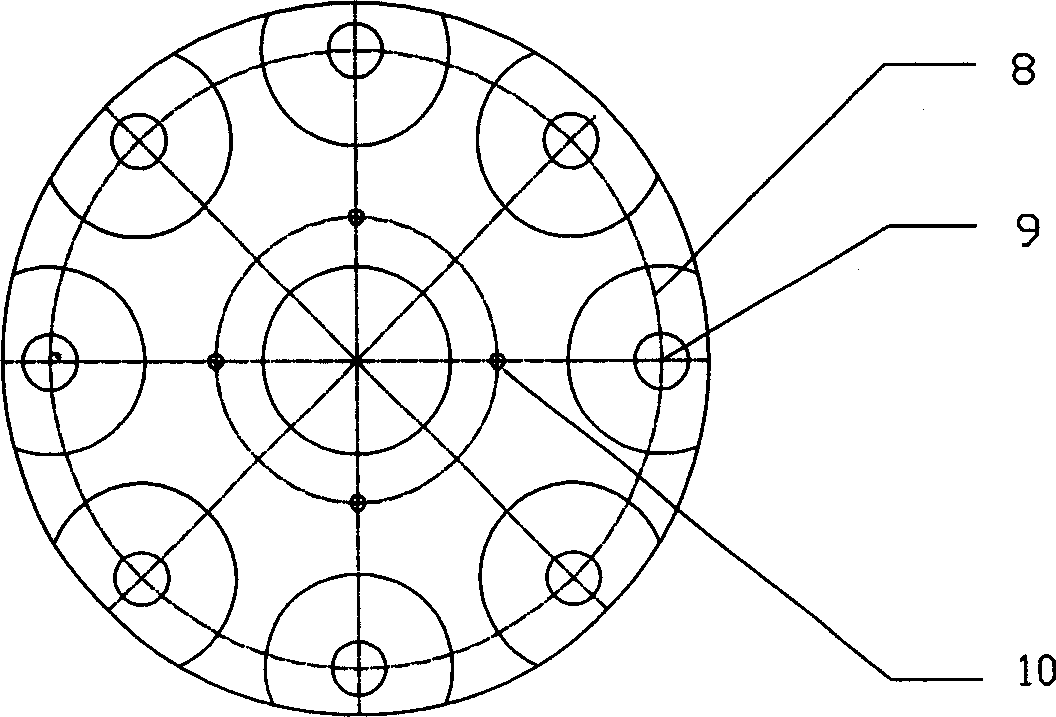

[0012] Planar bearings 11 are provided on the workbench 3 . There are 8 circular sunken drainage grooves 8 evenly distributed along the circumference on the rotating circular platform 1, so as to facilitate the liquid discharge when using liquid cooling medium for cooling; The concentric sample bracket fixing holes 9 are used to install the sample bracket 2; 4 positioning holes 10 evenly distributed along the circumference are used to install the positioning device 6; Realize the thermal shock resistance test of multiple samples.

[0013] The sample holder 2 is installed on the rotating circular platform 1 through screw connection, and a flow hole 12 is opened on the upper part thereof. The numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com