Optical-fibre and grating acoustic transmitting and temperature sensor

A technology of temperature sensor and optical fiber grating, applied in the field of sensors, can solve problems such as fear of electromagnetic interference, inability to monitor temperature at the same time, and long signal transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

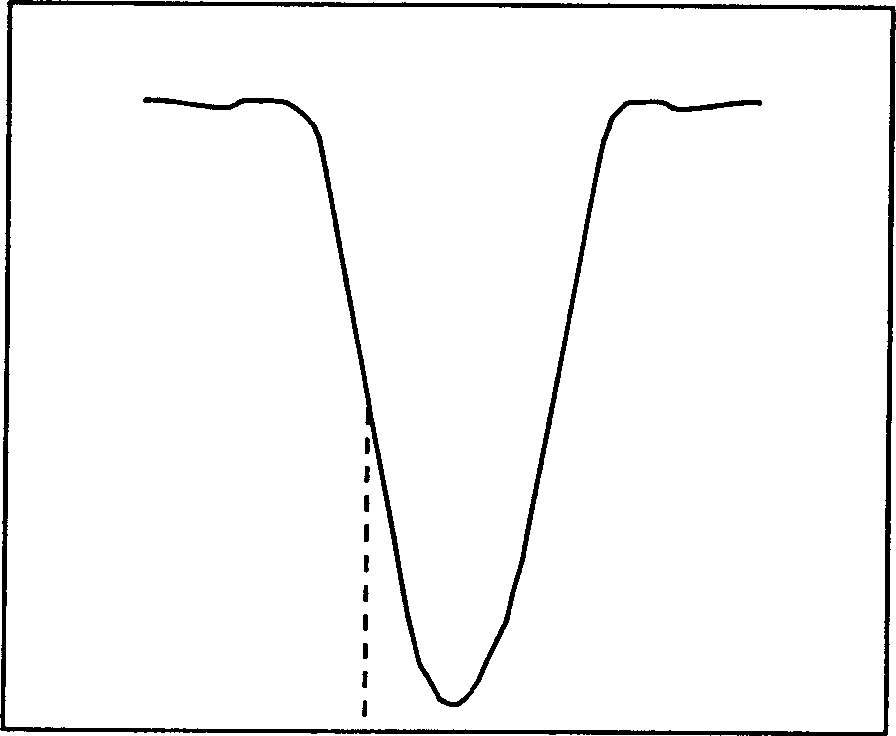

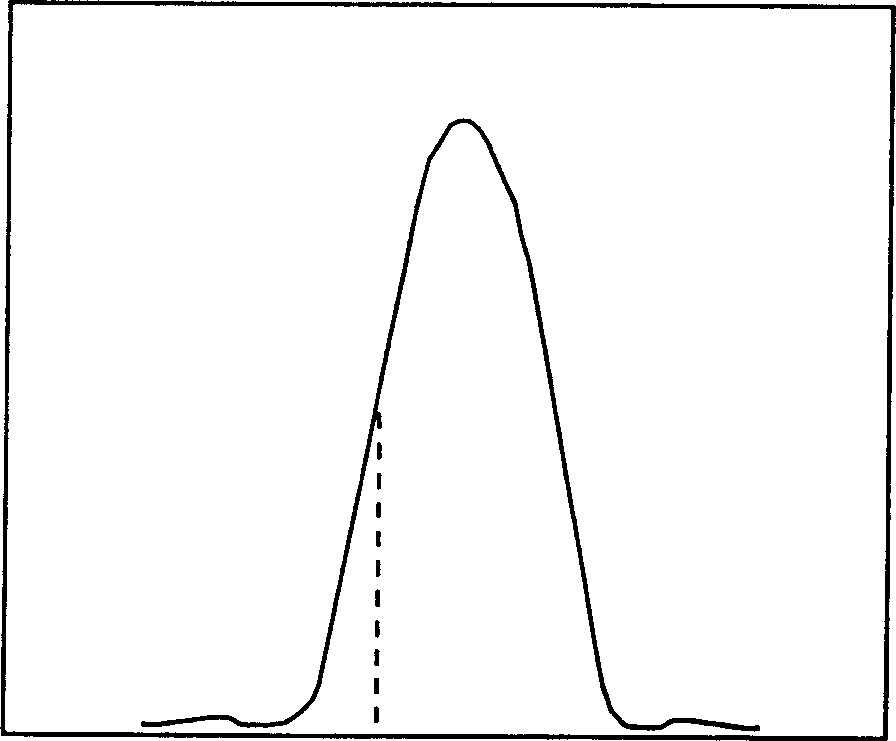

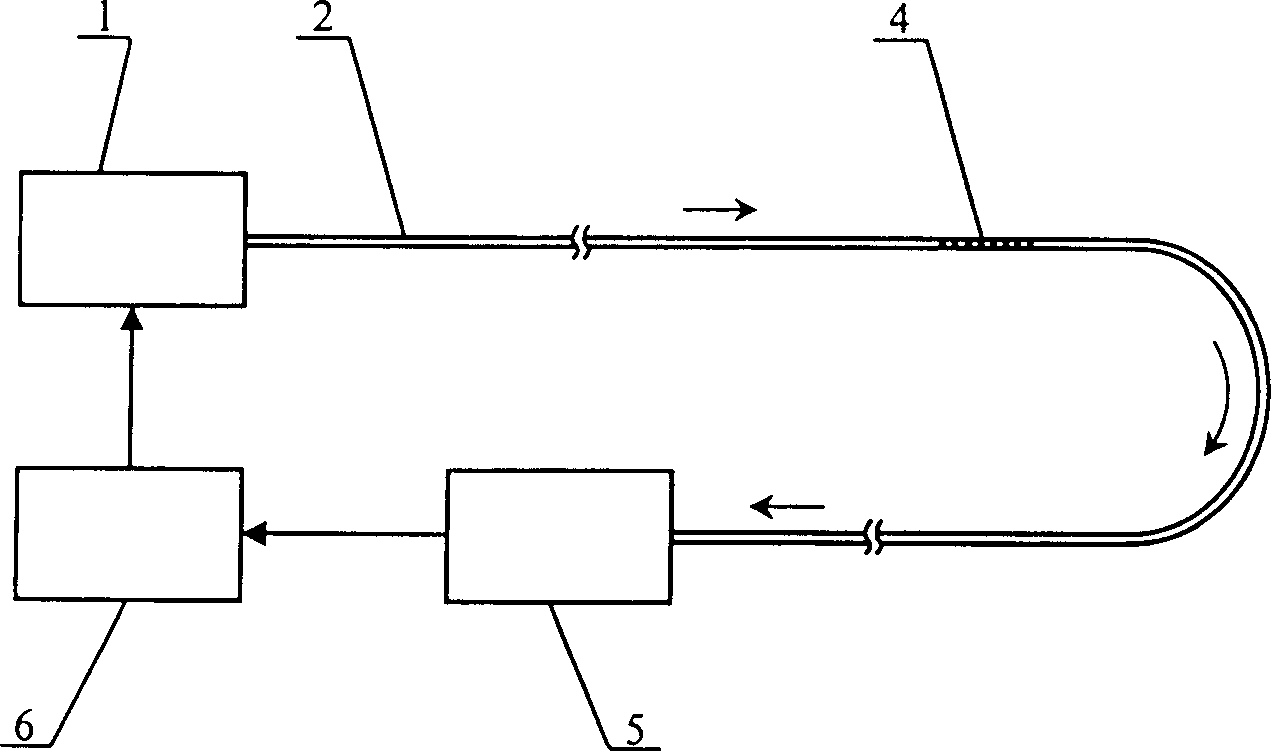

[0047] figure 2 The structure of the first embodiment of the present invention is shown, and the fiber grating acoustic emission and temperature sensor of the present embodiment includes: a laser 1 connected in sequence with an optical fiber 2, a fiber grating 4, a receiving unit 5 and the laser 1 and the laser The receiving unit 5 is electrically connected to the control unit 6 . The arrows in the figure indicate the traveling direction of the optical signal. The working wavelength of the laser 1 is located on the slope of the resonance peak of the fiber Bragg grating 4 , and its outgoing light enters the fiber Bragg grating 4 , and enters the receiving unit 5 after being transmitted by the fiber Bragg grating 4 . The receiving unit 5 converts the optical signal transmitted by the fiber grating 4 into an electrical signal, and provides feedback to the control unit 6 . The laser 1 has a manipulation parameter, the magnitude of which is controlled by the control unit 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com