Passive thermo-responsive initiator for extinguishment

A heat-sensitive, starter technology, applied in fire rescue, etc., can solve problems such as large frictional resistance, loss of bottle mouth sealing gasket compression, affecting action sensitivity, etc., to achieve reasonable structural design, good environmental adaptability, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

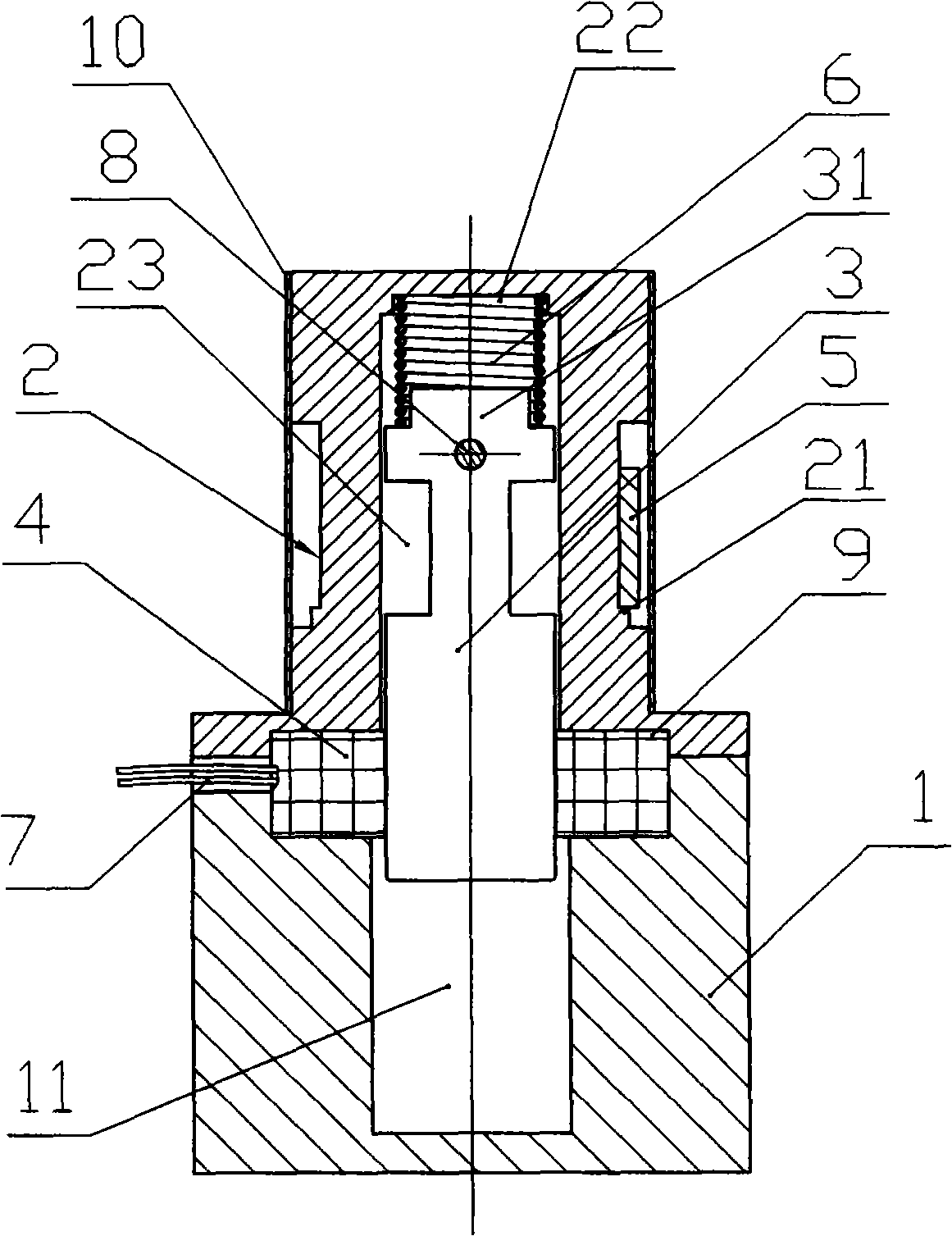

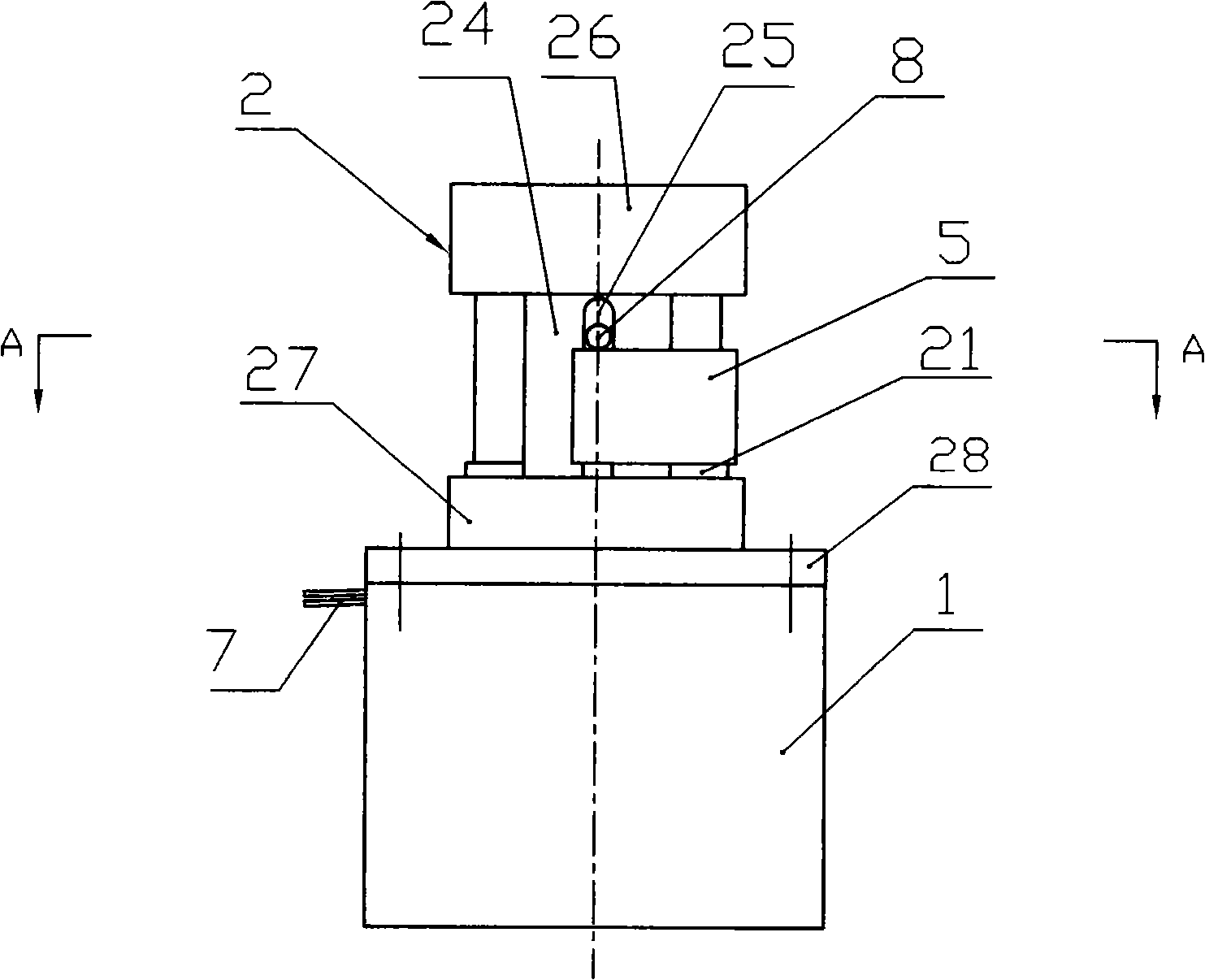

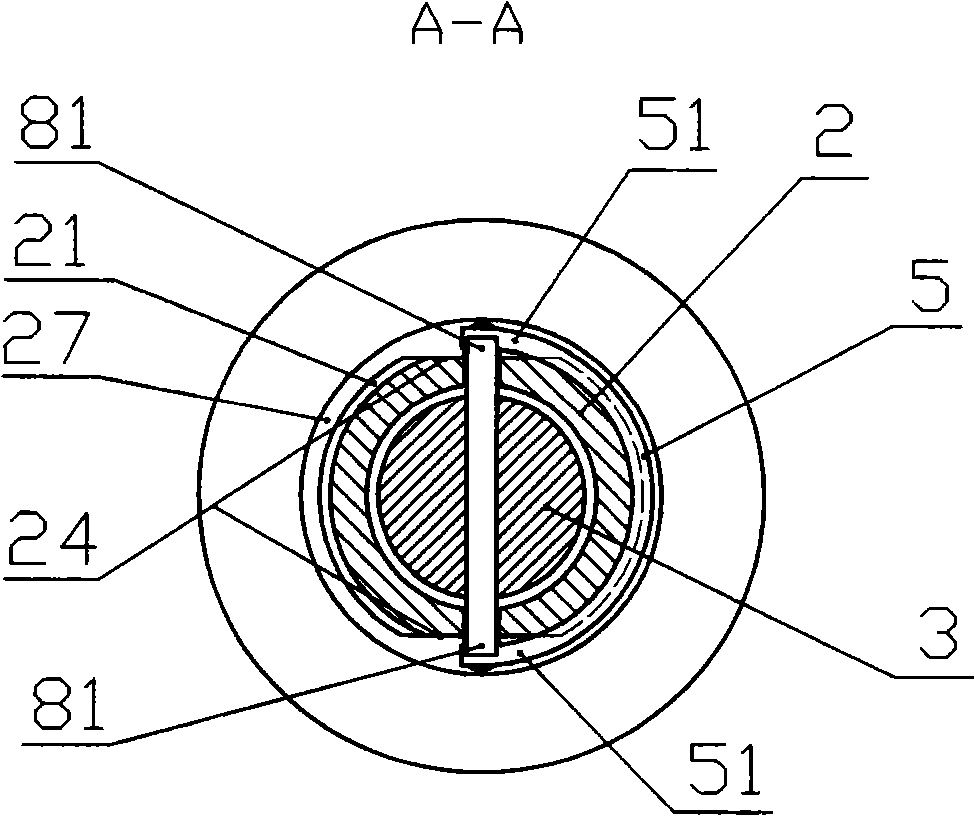

[0021] see Figure 1~3 , the starter includes a base 1 and a cap body 2 with a brim buckled on the base, a magnetic power supply is installed in the base 1 and the cap body 2, and the magnetic power supply consists of a magnetic rod 3 and a sleeve The armature 4 on the magnetic rod is composed of an upstroke chamber 23 of the magnetic rod 3 in the cap body 2, a downstroke chamber 11 of the magnetic rod 3 is provided in the base 1, and the butt joint of the upper and lower stroke chambers An armature chamber 9 with an enlarged diameter is provided, and the magnet rod 3 is installed in the upper and lower stroke chambers 23, 11. The armature 4 is installed in the armature chamber 9. When the cap body 2 is fixed on the base 1 When the armature cavity 9 is closed, the armature 4 is axially fixed, and the lead wire 7 of the armature is drawn out through the lead wire hole on the base 1 or the cap body 2 . The cap body 2 is provided with a heat-sensitive ejection mechanism of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com