Intensified mixed coagulation and dynamic film integrated waste water treating process

A sewage treatment and dynamic membrane technology, applied in the field of environmental engineering, can solve the problems of large sewage discharge and insufficient treatment capacity of sewage treatment facilities, and achieve the effect of large sewage volume, small footprint, reduced load and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

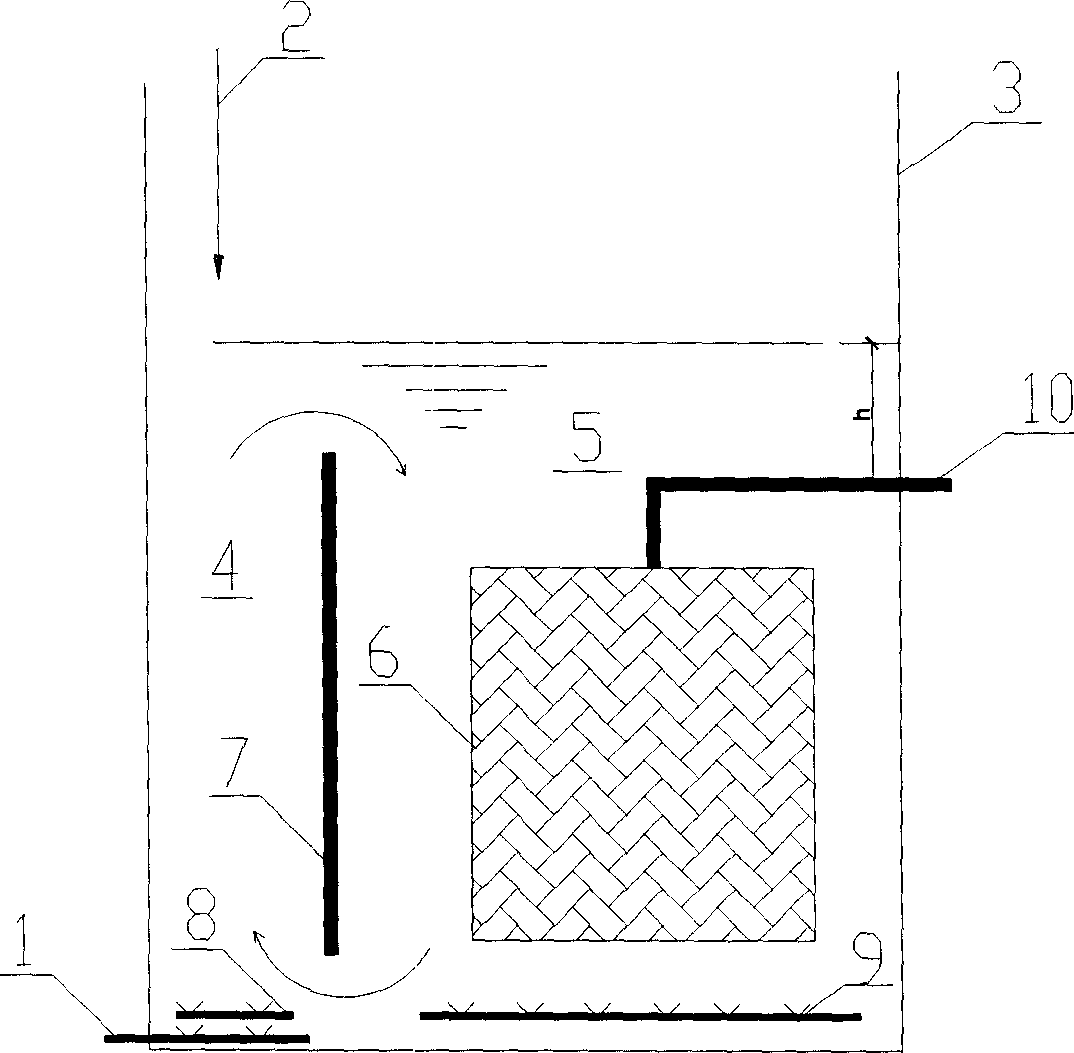

[0027] Such as figure 1 As shown, the sewage treatment device includes a reactor 3 (including a coagulation reaction zone 4 and a dynamic membrane zone 5 ), a dynamic membrane 6 , a water distribution pipe, a deflector 7 of the coagulation reaction zone 4 , and aeration pipes 9 and 10 . Sewage treatment methods are as follows:

[0028] The sewage is directly introduced into the reactor, and the coagulant PAC (polyaluminum chloride) is added into 2 from the top of the coagulation reaction zone 4. In the coagulation reaction zone 4, the sewage and the added coagulant are exposed on the bottom side of the coagulation reaction zone Mixing under the action of air, the aeration volume of the aeration tube at the bottom of the coagulation reaction zone is 0.03m 3 / m 3 min. Circulation is formed in the entire reactor, and the sewage that is fully mixed with the coagulant can form a circulation in the reactor, and the treated water passes through the dynamic film formed on the non-w...

Embodiment 2

[0030] As described in Example 1, the difference is that the substrate 6 is sieve silk, and the coagulant is APAM (anionic polyacrylamide). The aeration volume of the aeration tube at the bottom of the coagulation reaction zone is 0.05m 3 / m 3 min.

Embodiment 3

[0031] Embodiment 3: As described in Embodiment 1, the difference is that the substrate 6 is a screen, and the coagulant is selected from CPAM (cationic polyacrylamide). The aeration volume of the aeration tube at the bottom of the coagulation reaction zone is 0.02m 3 / m 3 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com