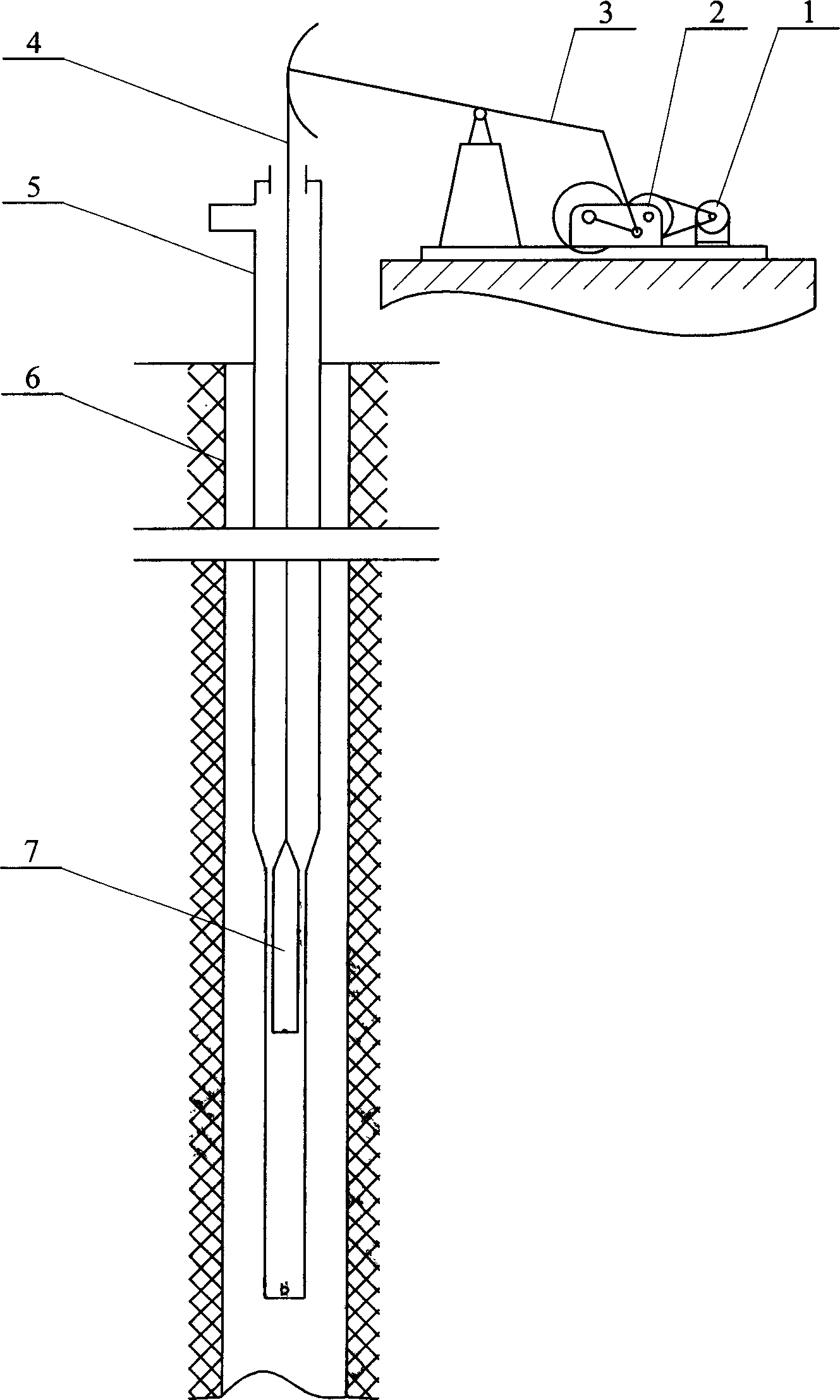

Underground reciprocating oil puming machine driven by rotary motor

A rotating motor and reciprocating technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of increased size, large inertial load, high energy consumption, etc., and achieve improved performance, small inertia, and flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

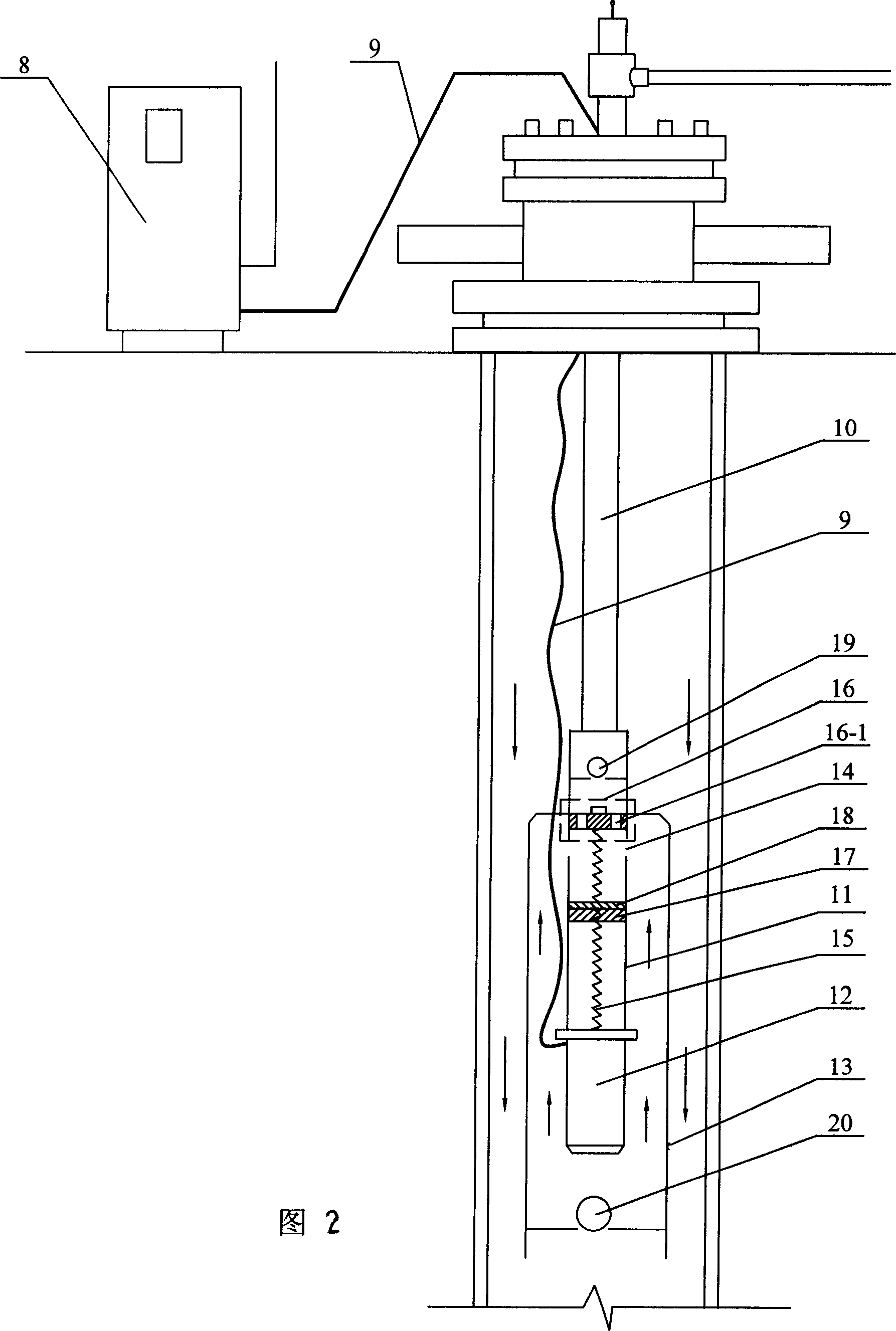

[0034] Embodiment 1: This embodiment is an underground reciprocating pumping unit driven by a rotating motor, which includes a motor controller 8, a cable 9, an oil outlet pipe 10, a plunger barrel 11, a motor 12, and a buffer oil pipe 13. The lower end of the oil outlet pipe 10 is sealingly connected with the plunger barrel 11, and the lower end of the plunger barrel 11 is provided with a motor 12, and a buffer oil pipe 13 is set outside the motor 12, and the upper end of the buffer oil pipe 13 is sealed with the outer wall of the plunger barrel 11 To connect, an oil suction hole 14 is provided on the inside of the buffer oil pipe 13 and on the side wall of the plunger barrel 11 , and a one-way oil inlet valve 20 is arranged in the buffer oil pipe 13 below the motor 12 . Both ends of the cable 9 are respectively connected with the motor controller 8 and the motor 12;

[0035] A lead screw 15 is arranged inside the plunger barrel 11, and the lower end of the lead screw 15 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com