Pipe blade assembling machine for rectangular shield

A segment assembling machine and rectangular shield technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of small action range and lack of segment assembling machine, etc. effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

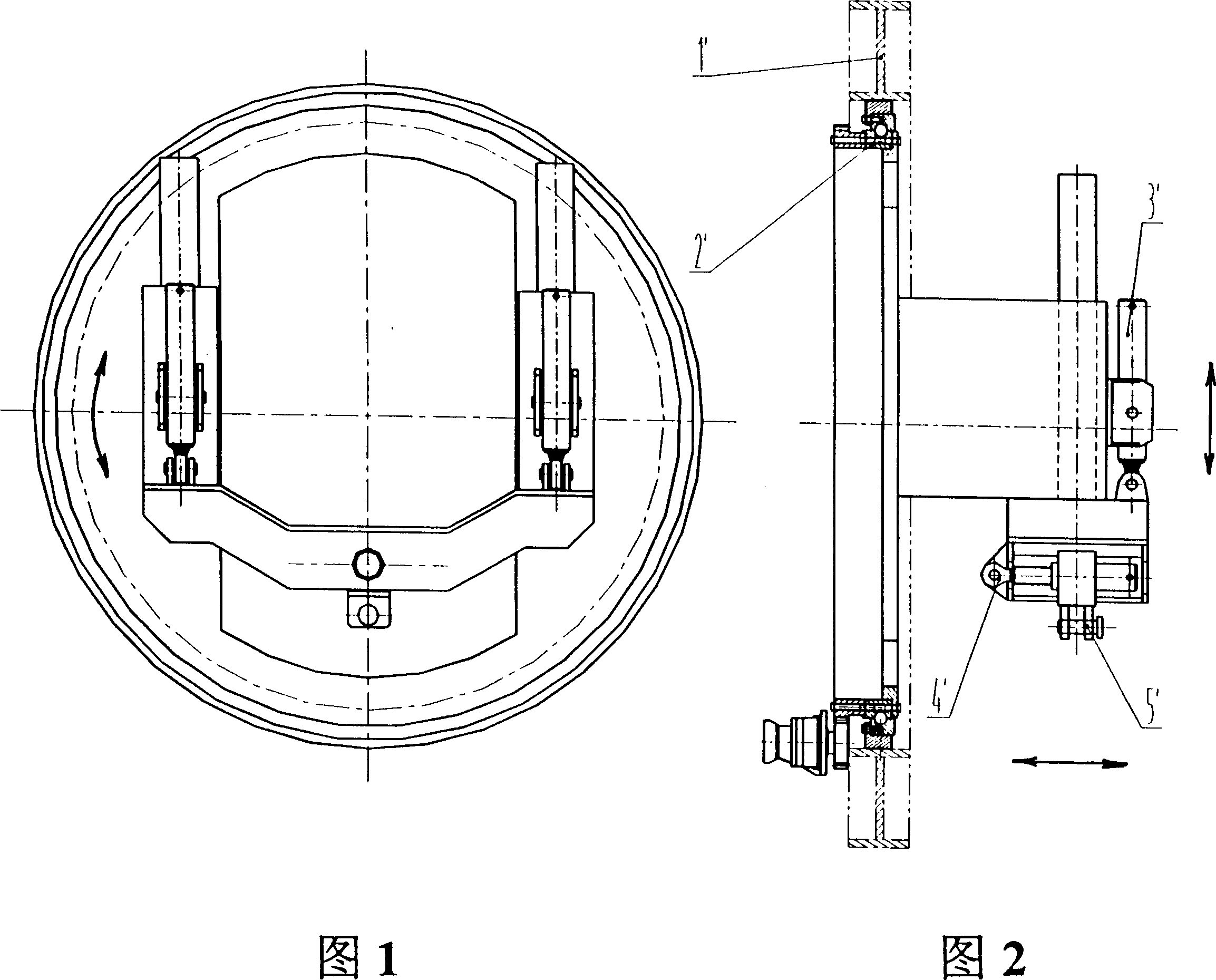

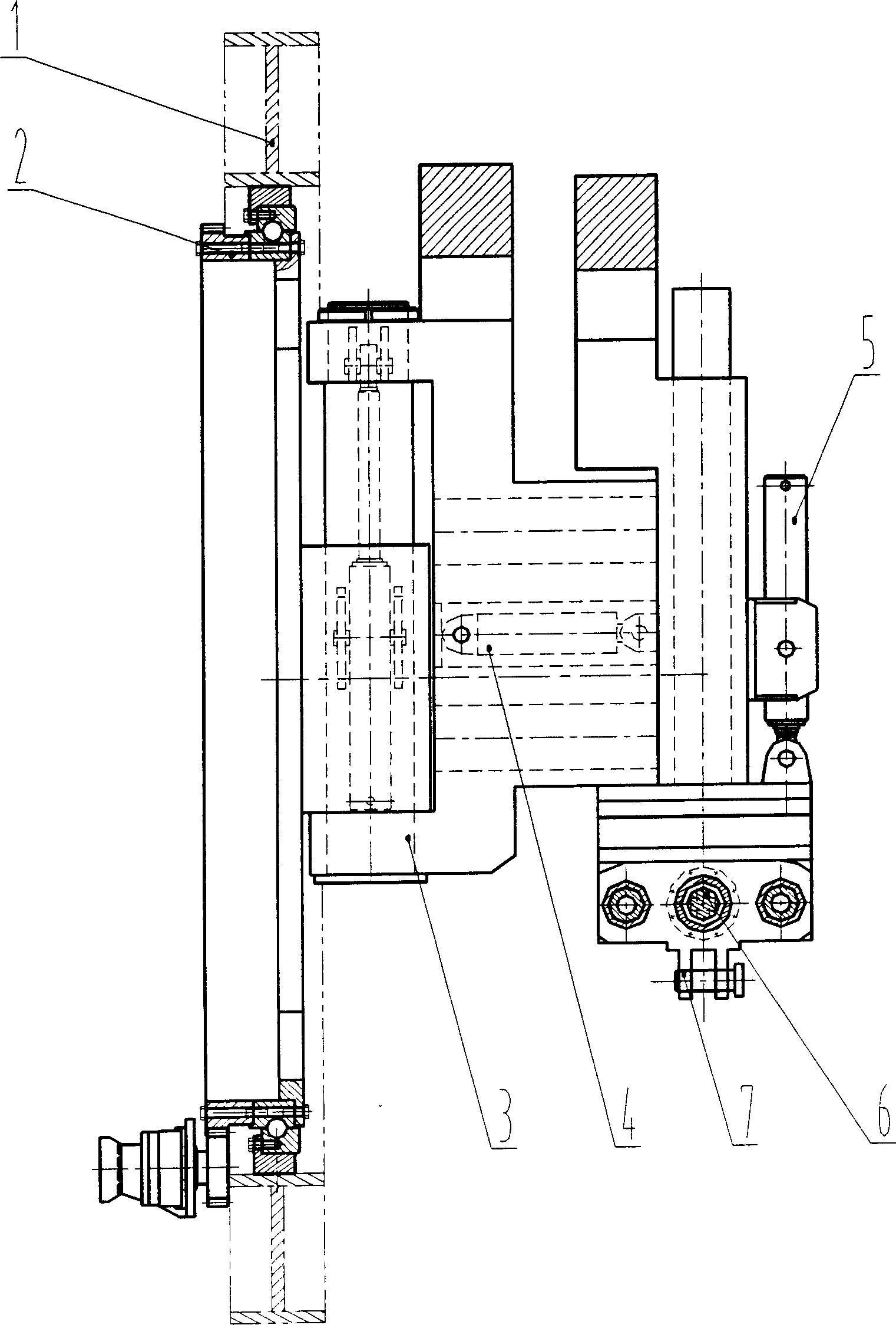

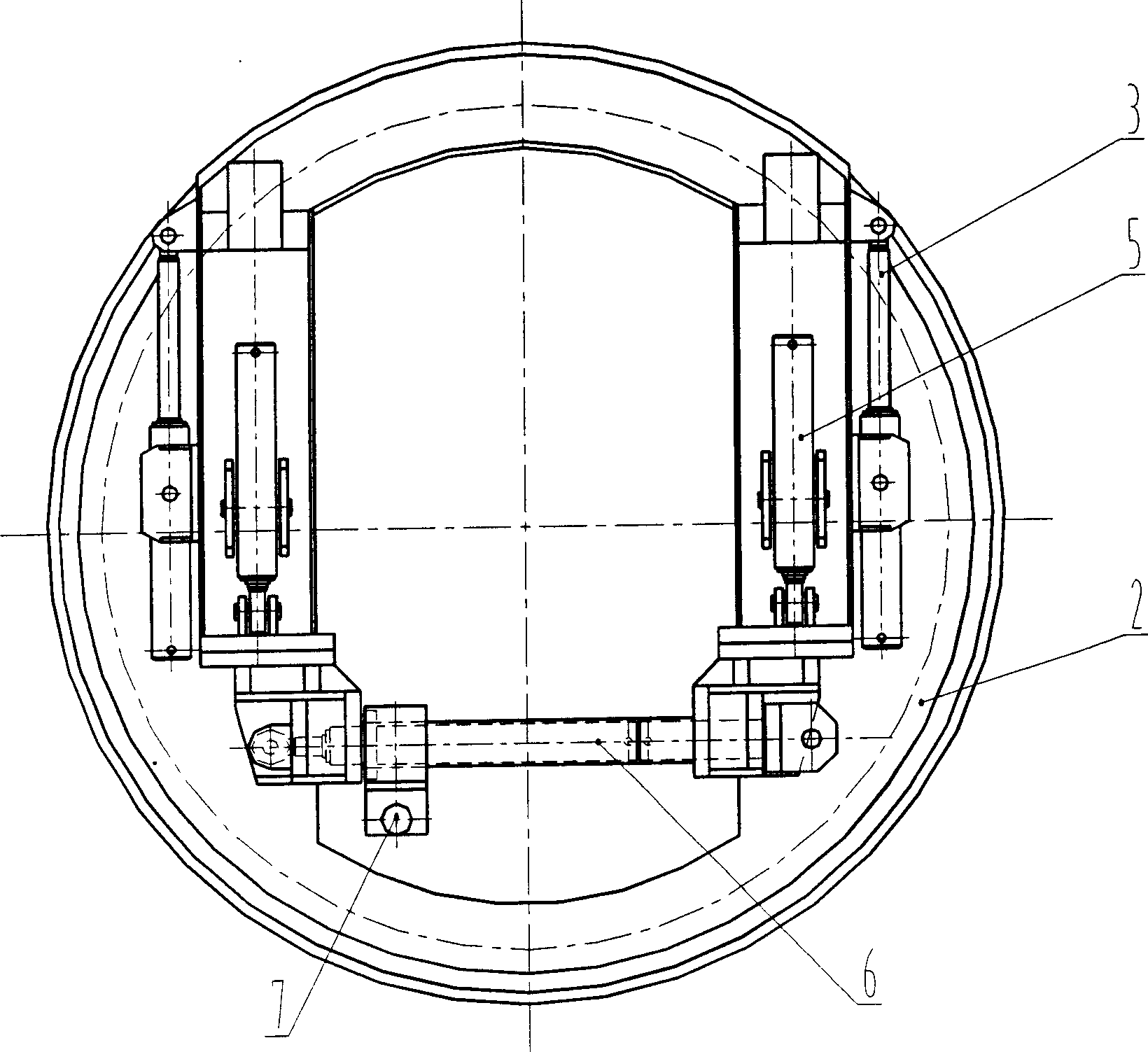

[0026] First, see image 3 with Figure 4 Schematic diagram of the structure of the present invention, which shows that the segment assembly machine for rectangular shield tunneling includes a support 1, a rotary device 2, a front-stage lifting device 3, a front and rear translation device 4, a lifting device 5, a left and right translation device 6 and a clamp head device 7 .

[0027] The support 1 is fixed on the inner casing of the shield machine, and the slewing device 2 is supported on the support 1 . Referring to Fig. 5 and Fig. 6 again, the rotary device 2 shown in the figure includes a support base 201, a bearing 202, a rotating disk 203 and a driving device 204; the support base 201 is fixed on the support 1, and the bearing 202 adopts large Bearing support can also adopt other support methods such as retaining wheel support, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com