Integrated starter/generator hybrid power system and controlling method

A hybrid system and starter generator technology, which is applied in hybrid vehicles, machines/engines, power units, etc., can solve the problems of large size of integrated starter generators, engine fuel consumption, and large exhaust emissions from automobiles. The effect of extending ambient temperature adaptability, reducing output torque requirements, ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

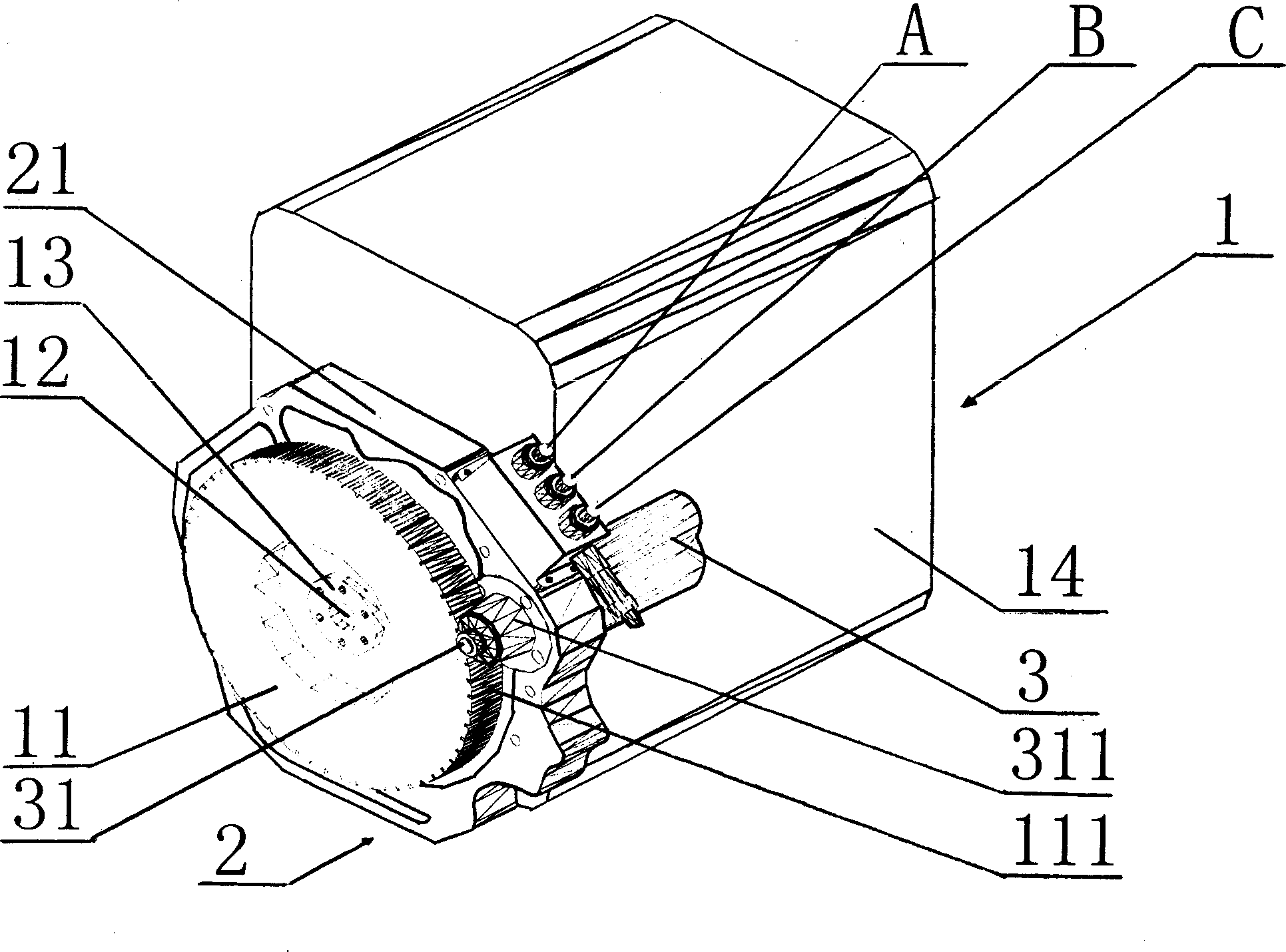

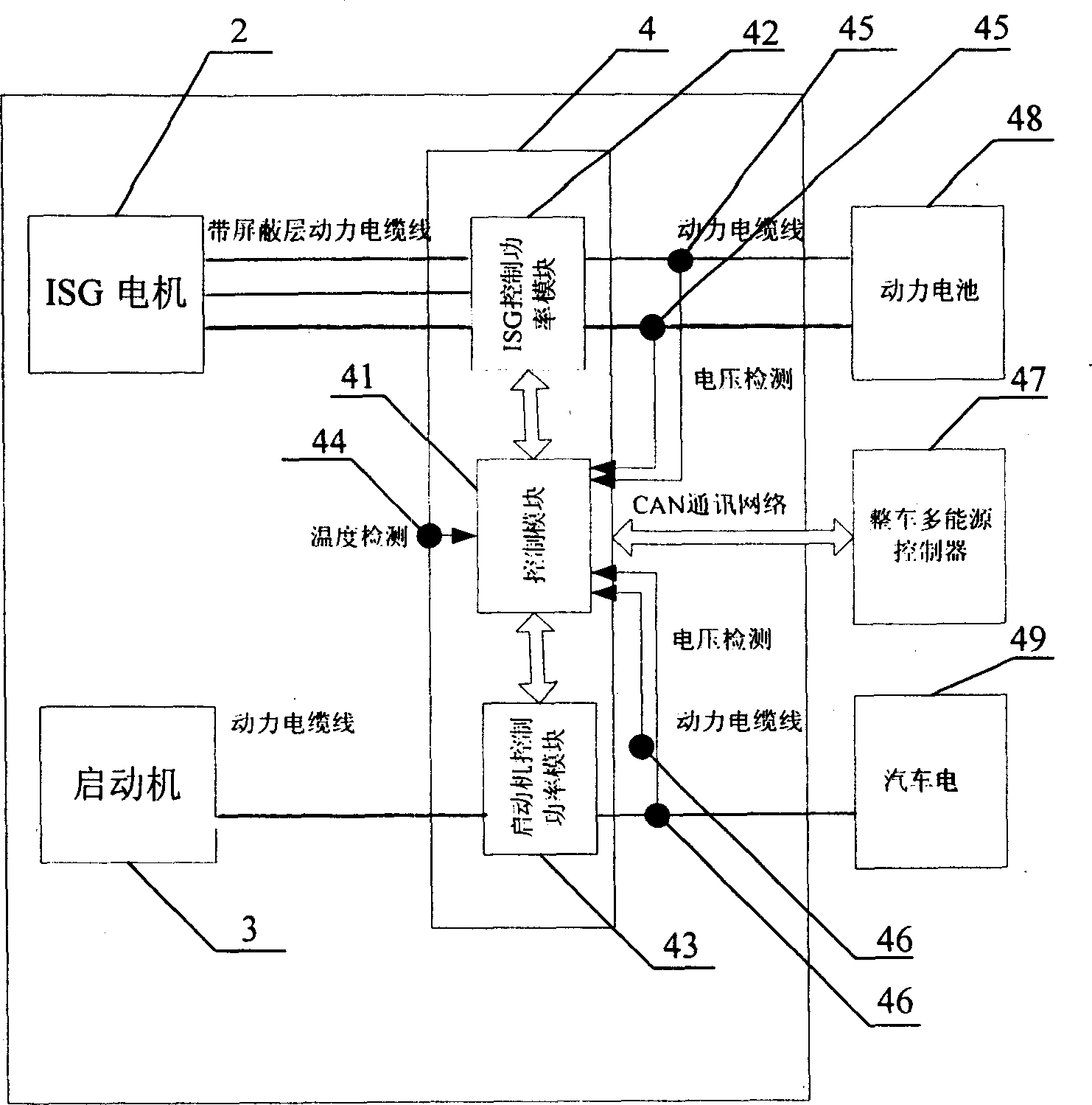

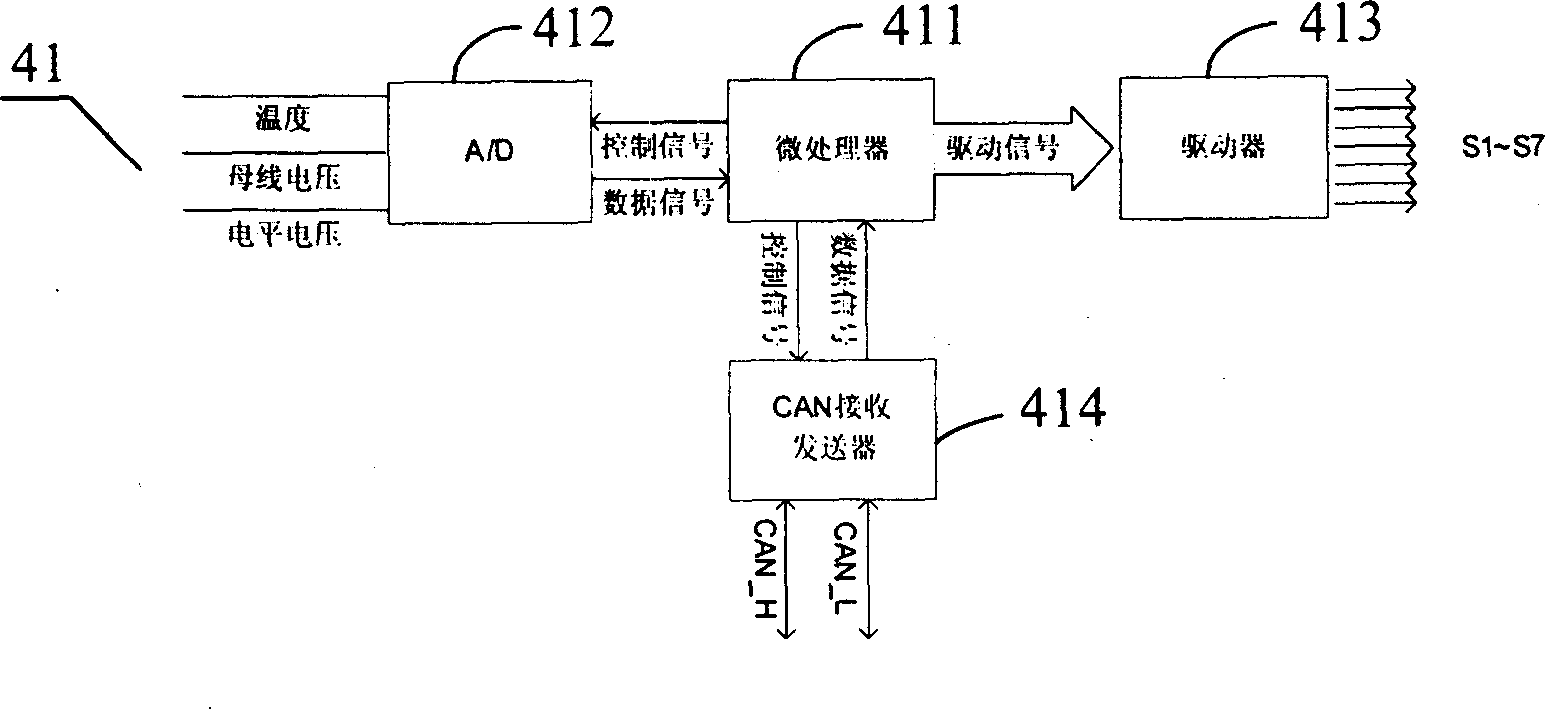

[0039] See figure 1 As shown, the integrated starter / generator hybrid power system includes: engine 1, integrated starter generator 2, starter 3 and controller 4; engine 1 main shaft 12 and integrated starter generator 2 main shaft are connected coaxially through flanges; The rotor of the integrated starter generator 2 is set on the main shaft 12 of the engine 1, and the stator 21 of the integrated starter generator 2 is fixed on the engine casing 14; the starter 3 is arranged on the stator 21 of the integrated starter generator 2, and the engine main shaft 12 is provided with a flywheel 11, the outer diameter of the flywheel 11 is provided with teeth 131, the teeth 131 are meshed with the teeth 311 provided on the outer diameter of the main shaft 31 of the starter 3, and the pressure plate 13 is arranged at the end of the engine main shaft 12, The flywheel 11 is firmly connected with the engine main shaft 12 . When the integrated starter generator 2 is started under control,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com