Multichannel fixed bed reacter and reaction method

A fixed-bed reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficulty in completion, and achieve low consumption of reaction materials, uniform temperature and pressure distribution, and shortened evaluation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

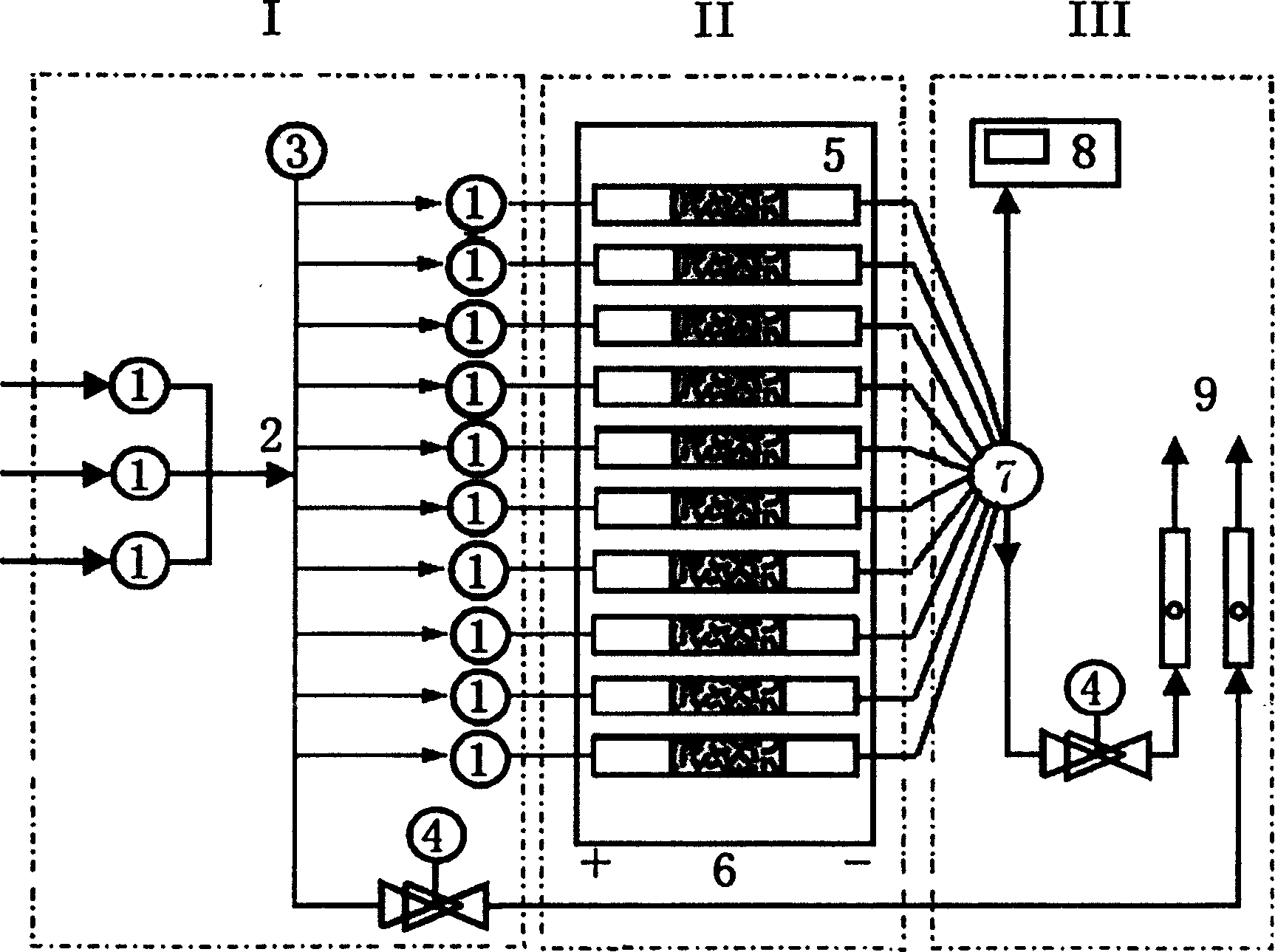

[0011] 10-channel fixed-bed reactor: 10 fixed-bed reactors with an inner diameter of 6mm, a length of 100mm, and a thickness of 2.5mm are processed by stainless steel materials. Reactants A, B, and C are decompressed and controlled by mass flow meters 1a, 1b, and 1c respectively. Entering the splitter 2, the ends of the 10 gas paths distributed from the splitter are threaded to the front ends of the 10 parallel fixed bed reactors, the ends of the 10 reactors are threaded to the front ends of the multi-way valve, and the ends of the multi-way valve are threaded. It is connected with the mass spectrometer detector, and the excess product is discharged from the vent valve.

Embodiment approach 2

[0013] Hydrogenation of carbon monoxide to methanol: Weigh 1 g of each of the 8 prepared solid powder catalysts and put them into the middle of a titanium alloy reactor with an inner diameter of 8 mm, a length of 120 mm, and a thickness of 3 mm. After tightening both ends of the device, put it into the oil bath, open the ball valve and fill in the reaction gas (H 2 / CO=2) to 1.5MPa for 10 minutes to prove that the reaction vessel is well sealed, then refill the reaction gas three times, replace the air in the system, adjust the temperature of the oil bath to 170°C, adjust the back pressure valve to control the reaction pressure to 1.0MPa, h 2 / CO=2, the products flowing out from the 8 reactors were switched to a mass spectrometer detector (Agilent 5973MSD) through a multi-way valve for online analysis.

Embodiment approach 3

[0015] Synthesis gas one-step synthesis of dimethyl ether: Weigh 0.3g of 50 prepared solid powder catalysts and put them into 50 stainless steel reactors with an inner diameter of 6mm, a length of 160mm, and a thickness of 2mm in the middle of the stainless steel reactor, and both ends are blocked with quartz wool. All 50 reactors were put into the oil bath after being tightened at both ends, and the ball valve was opened to fill in the reaction gas (H 2 / CO=1) to 1.5MPa for 10 minutes to prove that the reaction vessel is well sealed, then refill the reaction gas three times, replace the air in the system, adjust the temperature of the oil bath to 190°C, adjust the back pressure valve to control the reaction pressure to 1.2MPa, h 2 / CO=1, the products flowing out from the 50 reactors are switched to the QIC20 mass spectrometer through the multi-way valve for online analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com