Grill bearing baffler of shell-and-tube heat exchanger

A shell-and-tube heat exchanger, heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. Reduce the heat transfer efficiency, reduce the rigidity and strength of the baffle rod, and achieve the effect of excellent tube bundle structural strength and rigidity, increase rigidity, and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

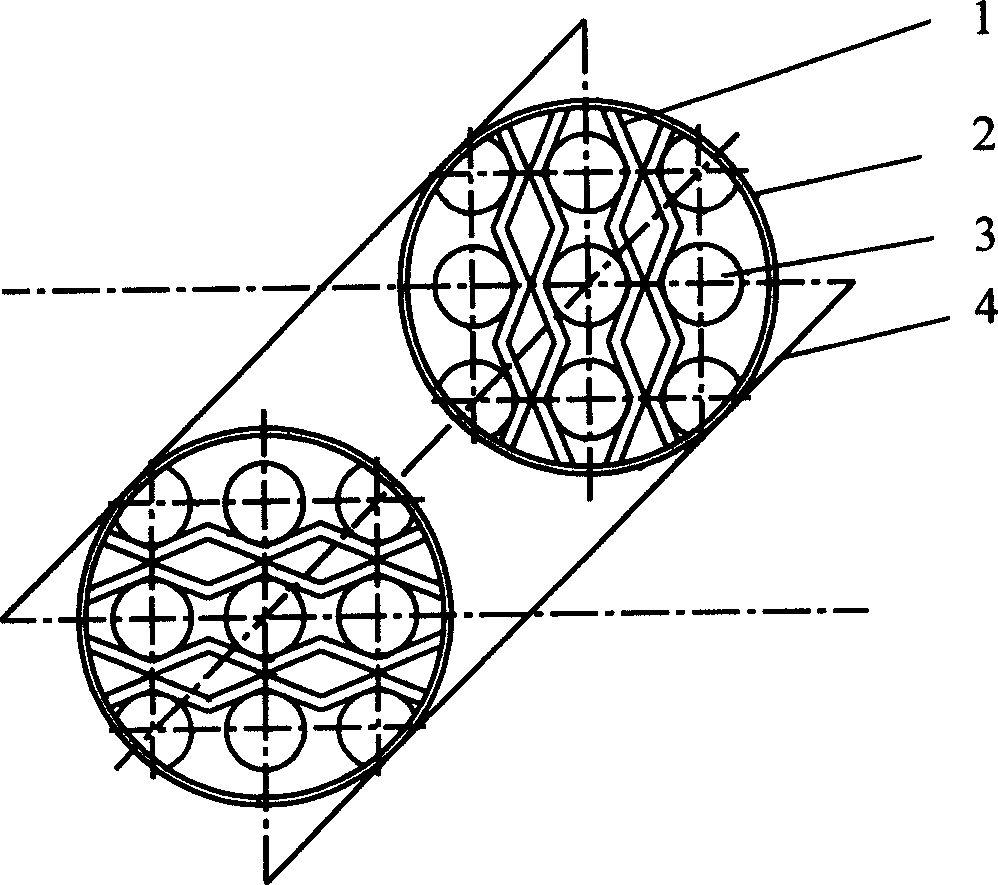

[0017] Such as figure 1 As shown, the shell-and-tube heat exchanger grid supporting and deflecting device of the present invention includes a heat exchange tube 3, a heat exchanger shell 4, a grid 1, a confining ring 2, and the heat exchange tube 3 passes through the grid 1. Multi-point holding support. The grid 1 is a grid 1 with four arcs and eight supporting points arranged in a staggered 90° staggered manner by two grid plates. Each pair of grid plates are parallel at the same interval. Arranged and welded in the limiting circle 2.

[0018] The invention is based on the shell-and-tube heat exchanger, adding a grille and a confining ring. The grid can be plate or wire. When designing the grid, the heat exchange tube spacing t is determined first, and the grid plate thickness δ or wire diameter φ is selected according to the tube spacing t, so that δ or φ is 1 / 2 of t. After the plate or wire is extruded and formed, the template is used for butt formation with the limited ring, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com