Method of producing a porous membrane and waterproof, highly breathable fabric including the membrane

A porous membrane and fabric technology, applied in chemical instruments and methods, separation methods, transportation and packaging, etc., can solve the problem that the flow cannot be controlled by the pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] PVDF powder with a solids content in the range of 10%-20% was dissolved in a mixing vessel with one of the solvents listed in Table I. PVDF is in powder form. In the case of a container equipped with a stirring device, the solvent is added to the powder and mixed. The solution should be stirred well until there is no sign of any solid powder. The solution is usually filtered through a fine mesh and drawn into a degassing vessel via a vacuum pump. Air is then introduced to compress the solution. This process was repeated until the liquid level did not rise under vacuum (due to outgassing).

[0117] The premix solution will have a very good shelf life if kept airtight to prevent any moisture from penetrating.

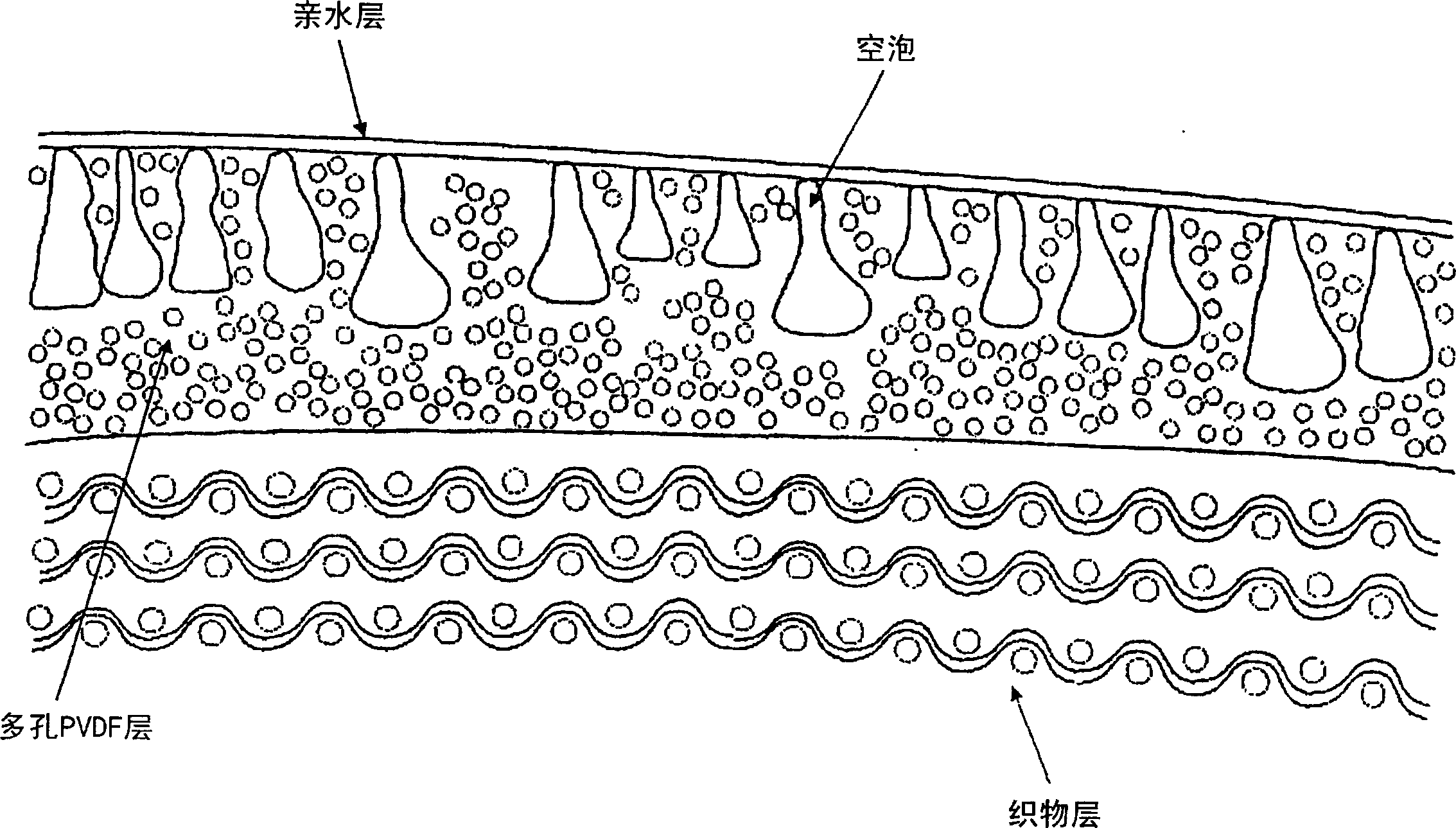

[0118] If the fabric will be coated, the fabric is pre-washed and all adhering particles and unwanted fine fibers are removed. Load the fabric onto the knife coater for coating. A solution of PVDF was fed into the knife coater as the fabric was pulled through...

Embodiment 2

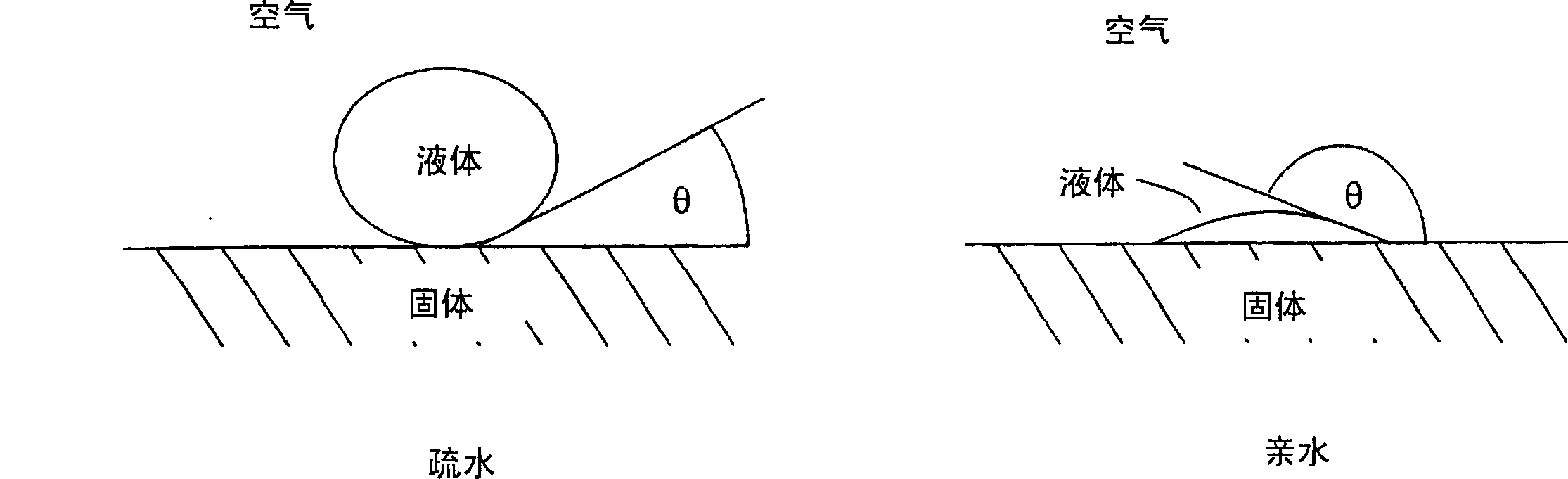

[0120] The non-solvent is water and the solvent is eg DMSO or DMAC. This reduces the surface tension of the non-solvent and thus the rate of diffusion of the solvent from the solution.

Embodiment 3

[0122] Add the fabric at the end of the non-solvent bath where the solvent content is high. When it reaches the other end of the developing tank, the solvent concentration is about zero, so all solvent is removed from the fabric. The fabric is then added to a drying tent to remove any non-solvent. Solvent content was controlled by discharge from the fabric feed end of the tank.

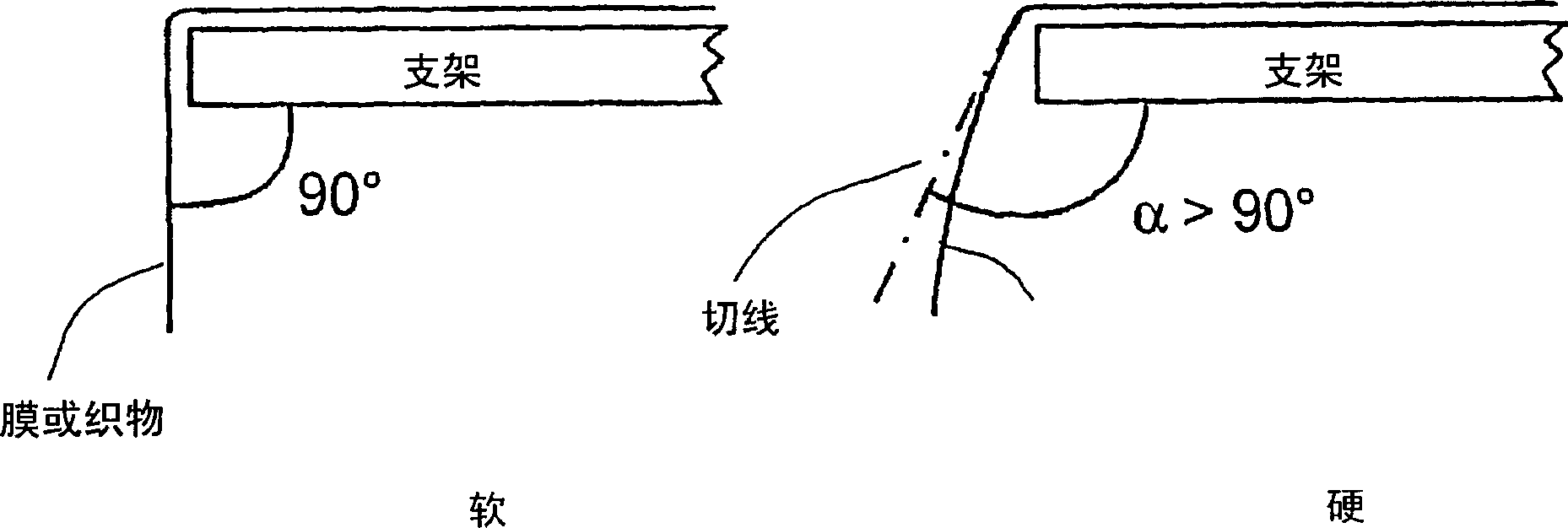

[0123] Tests have shown that if the fabric feed is passed through a highly hydrophobic non-solvent bath, it will be under strong compression due to the wrinkling caused by the compressive force of the porous structure during gelation. Once it gels, the wrinkled surface will not stretch without some damage.

[0124] If the non-solvent bath is hydrophilic, the fabric still needs to be under a high enough tension to be able to relieve the stress of the porous structure once the fabric tension is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com