Process for preparing diesel oil with polywater as raw material

A technology of diesel and raw materials, which is applied in the field of diesel production, can solve the problems of polluting the ground, polluting the atmosphere, and no treatment, and achieves the effects of reducing pollution, increasing income, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

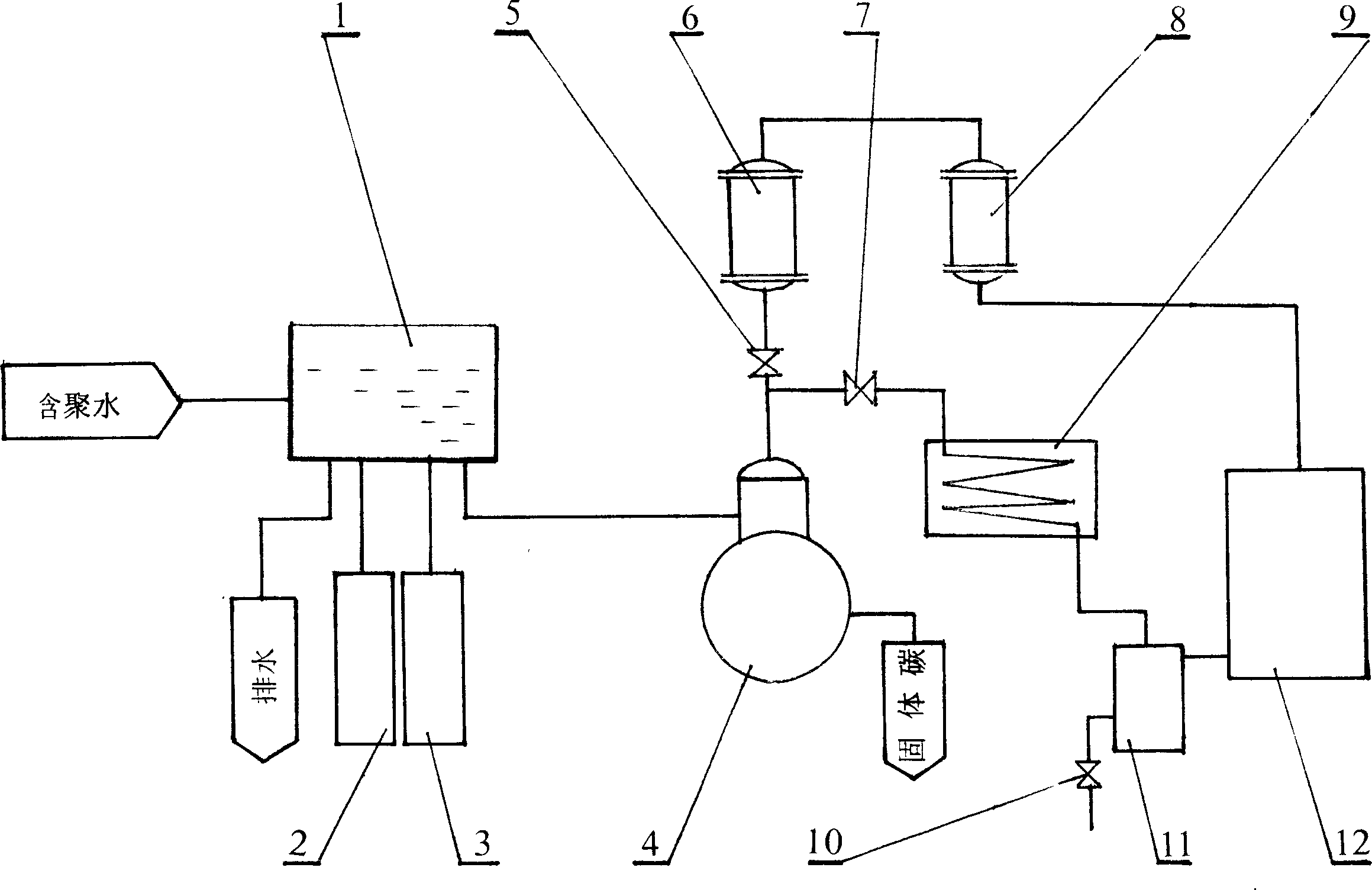

[0007] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0008] This production process is a discontinuous production process, which is carried out intermittently and operated under normal pressure.

[0009] The waste water containing polyacrylamide separated in the oil extraction process, that is, the polyacrylamide mentioned in the present invention, is sent to the recovery pool, and then pumped into the dehydrator 1, and the cold source provided by the refrigerator 2, the polypropylene The amide is separated by freezing, the temperature of the refrigerant is controlled at -5°C to -10°C, and the time is 8 to 24 hours under normal pressure. Due to the small specific gravity of polyacrylamide, the suspended polyacrylamide droplets are squeezed out during the freezing process. The upper layer contains a large amount of polyacrylamide, the ice layer is soft and easy to extract, and the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com