Method for preparing hollow ball shaped fire-extinguishing powder of ammonium phosphate salt by utilizing spray-drying process

An ammonium phosphate, drying process technology, used in drying solid materials, heating to dry solid materials, drying and other directions, can solve the problems of poor floating performance, poor fluidity, high density, etc., and achieve good fire extinguishing effect and good fluidity. , good floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

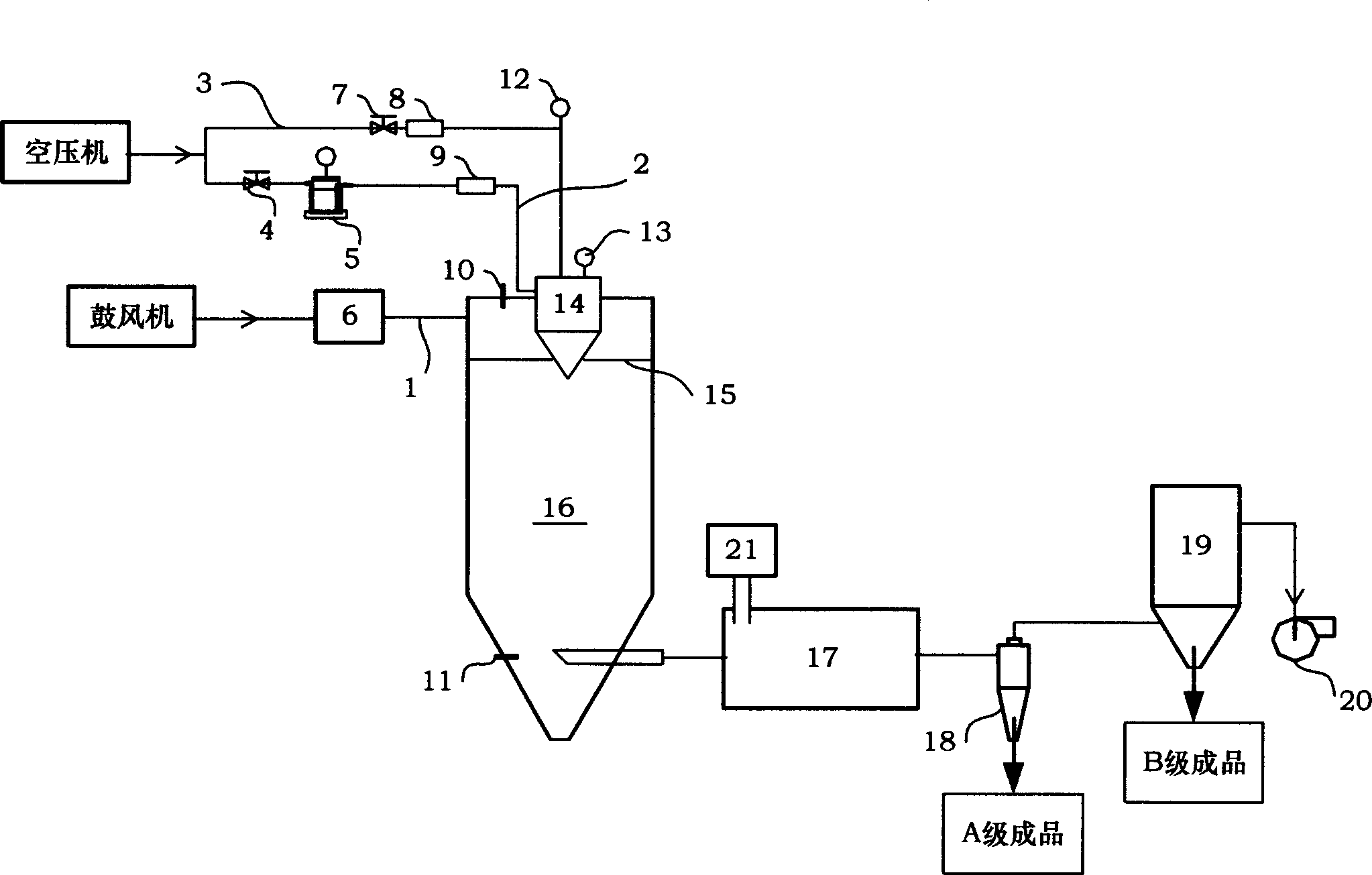

[0020] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0021] The present invention is a method for preparing hollow spherical ammonium phosphate fire extinguishing powder by spray drying process, the preparation process comprises the following steps:

[0022] (A) The air produced by the blower heated by the heating furnace 6 is transported to the drying chamber 16 through the A channel 1, and the flow rate of the hot air in the A channel 1 is 300-2000m 3 / h, the temperature of the hot air flow at the output end of channel A 1 is 150°C to 500°C;

[0023] (B) Send the compressed air generated by the air compressor in channel C 3 to the atomizer 14, the compressed air pressure is 0.3-0.8MPa, and the airflow velocity is 20-120m 3 / h;

[0024] (C) Dissolve ammonium dihydrogen phosphate, thickener, surfactant and foaming agent in water at 10°C to 99°C, and stir evenly to obtain a precursor solution; put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com