Composite vibration damping type photolithography device

A technology of lithography and active vibration reduction, which is applied in the direction of photolithography exposure devices, microlithography exposure equipment, electrical components, etc., can solve the problems of reduced dynamic stability, increased relative vibration modes of the optical axis, and increased synchronization errors. Large and other problems, to achieve good seismic/vibration performance, good dynamic characteristics, and the effect of isolating vibration transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

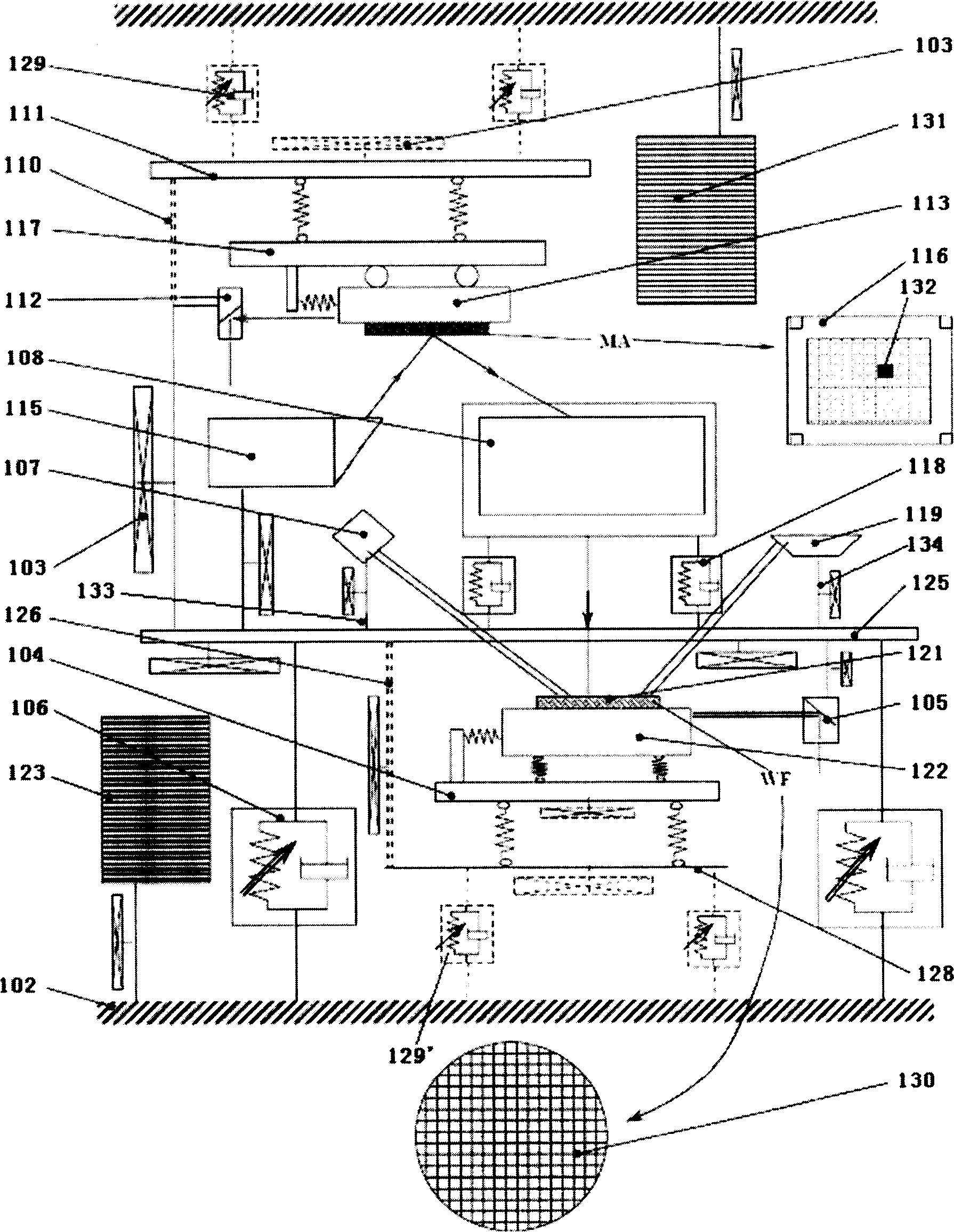

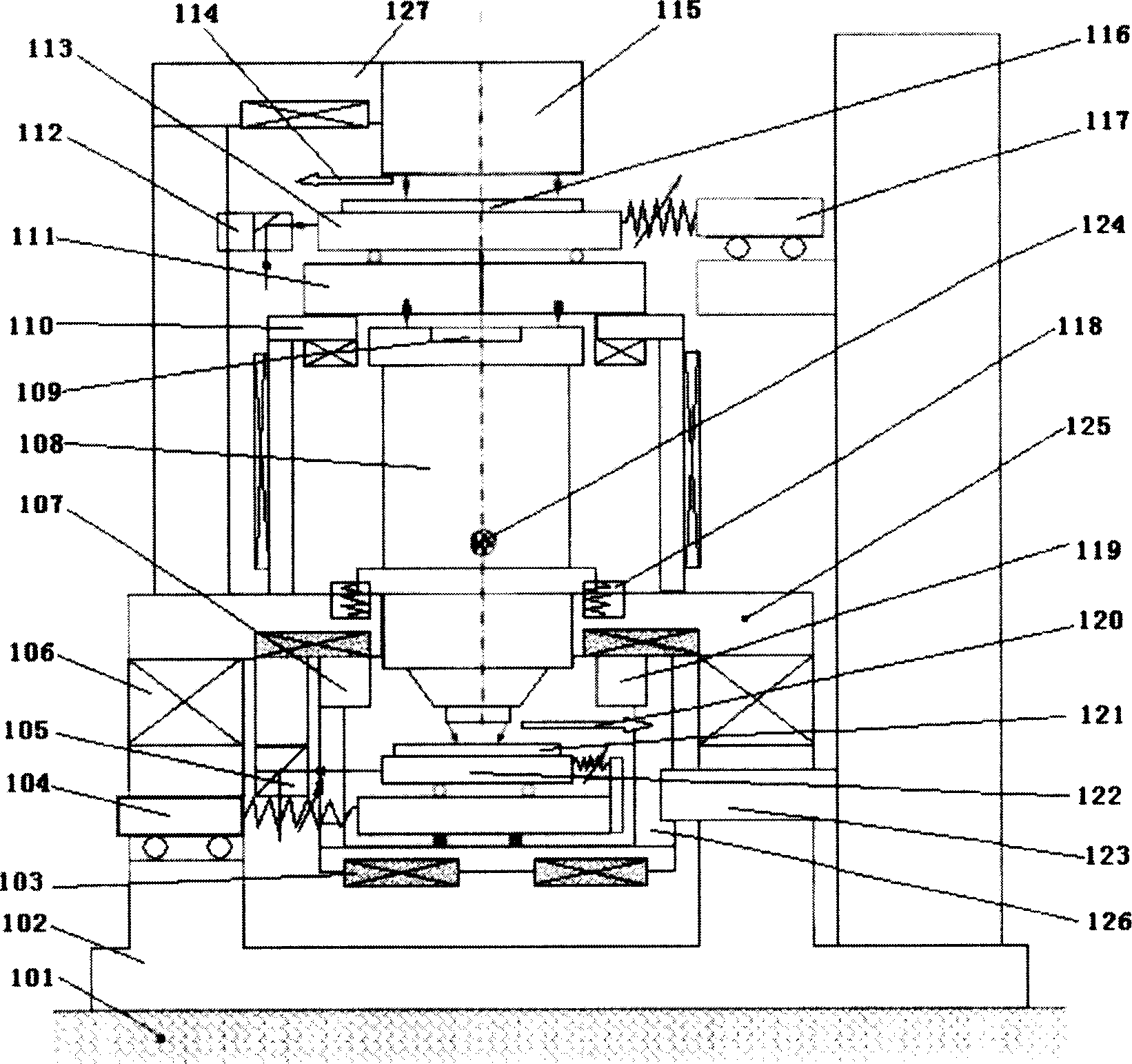

[0022] figure 1 , contains the specific implementation of the two design forms of the present invention, wherein the solid line part and the double dashed line part together constitute the design form of the unified active vibration isolation, and the solid line part and the single dashed line part together constitute the independent active vibration vibration isolation design form. The illumination system 115 provides projection beams, such as EUV and EUV light sources.

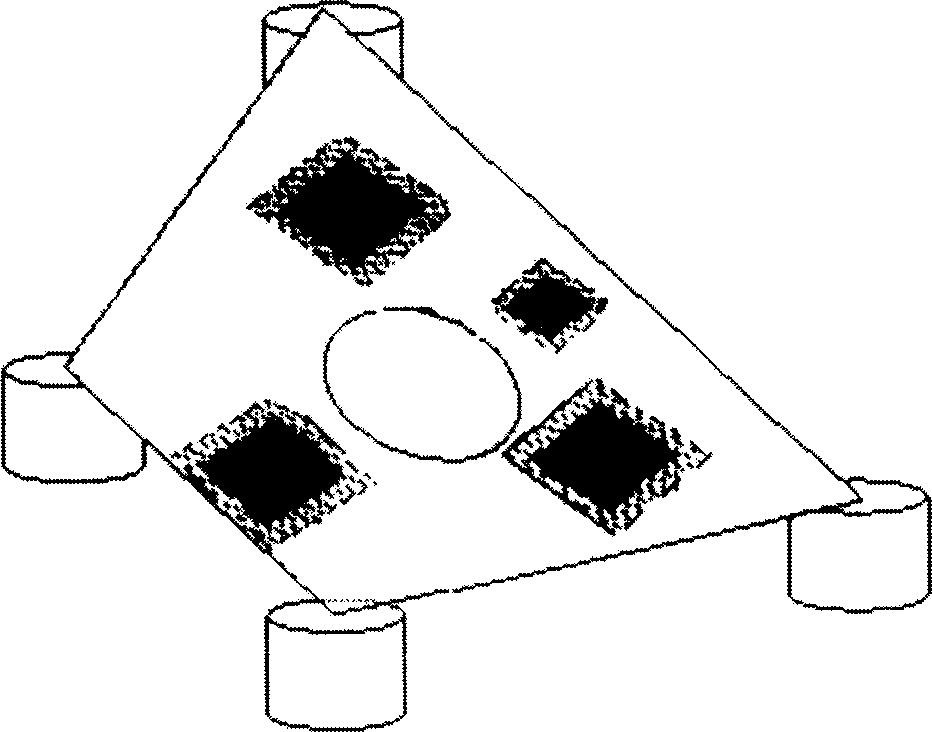

[0023] Such as figure 1 and figure 2 As shown, the entire lithography device is located on the vibration isolation foundation 101, the precision subsystems of the whole machine are organically linked together through the basic frame 102 of the whole machine, and the active vibration reduction system 106 is placed on the basic frame 102 of the whole machine, and all subsys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com