High precision positioning and accessing system for waste nuclear material

A positioning system, a technology for nuclear waste, applied in the control system, control/adjustment system, position/direction control and other directions, which can solve the problems of large shaking of hooks and waste buckets, large space occupied by waste buckets, and low degree of automation. , to achieve the effect of convenient and quick disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

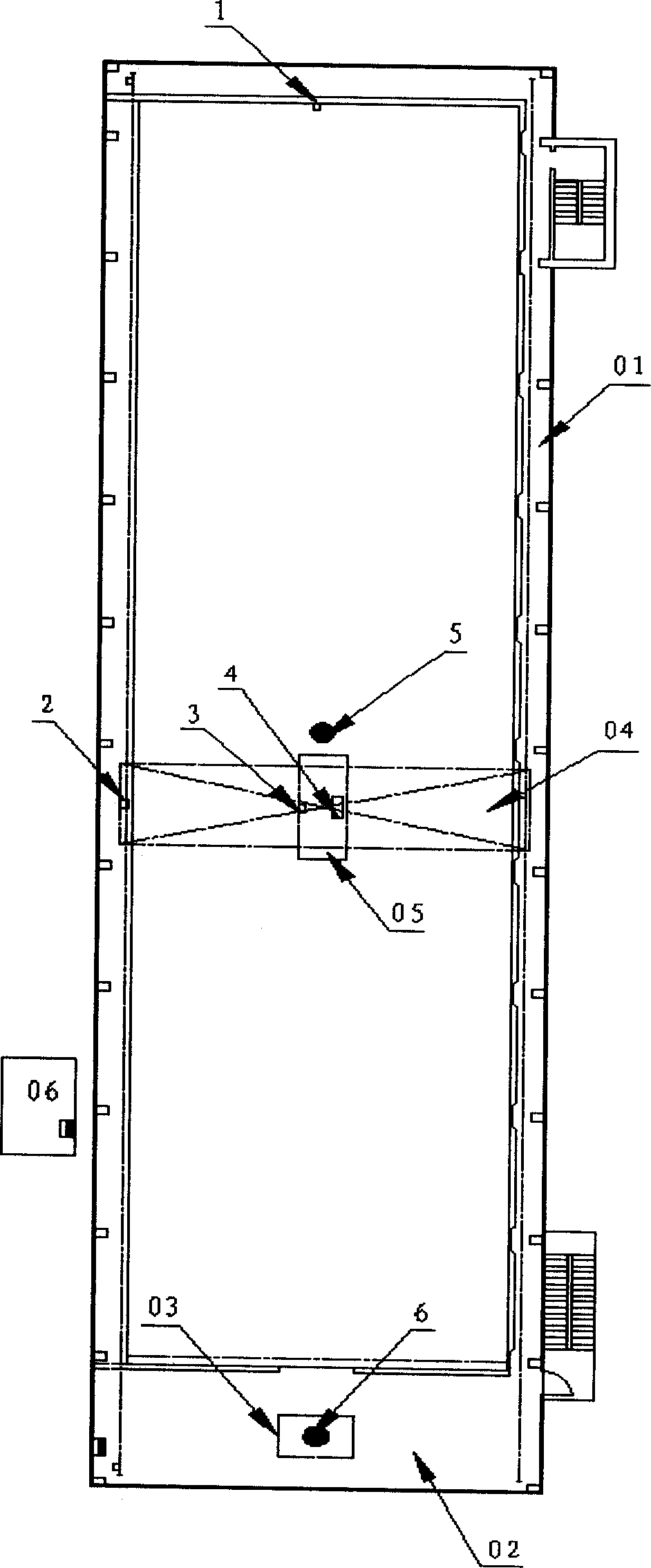

[0027] Such as figure 1 As shown, a control room 06 is added outside the waste barrel warehouse 01; a laser rangefinder 1 is installed on the wall of the warehouse 01 longitudinal (X direction) to monitor the position of the cart 04; the longitudinal axis of the cart 04 A laser rangefinder 2 is installed in the direction (Y direction) to monitor the position of the trolley 05; a rotary encoder 3 is installed on the trolley lifting motor to monitor the position of the spreader in the vertical direction (Z direction). The driveway camera 6 is installed on the ceiling above the waste bin import and export 03, the omnidirectional camera 5 is installed on the ceiling at the middle part of the warehouse 01, and the dolly camera 4 is installed on the dolly 05.

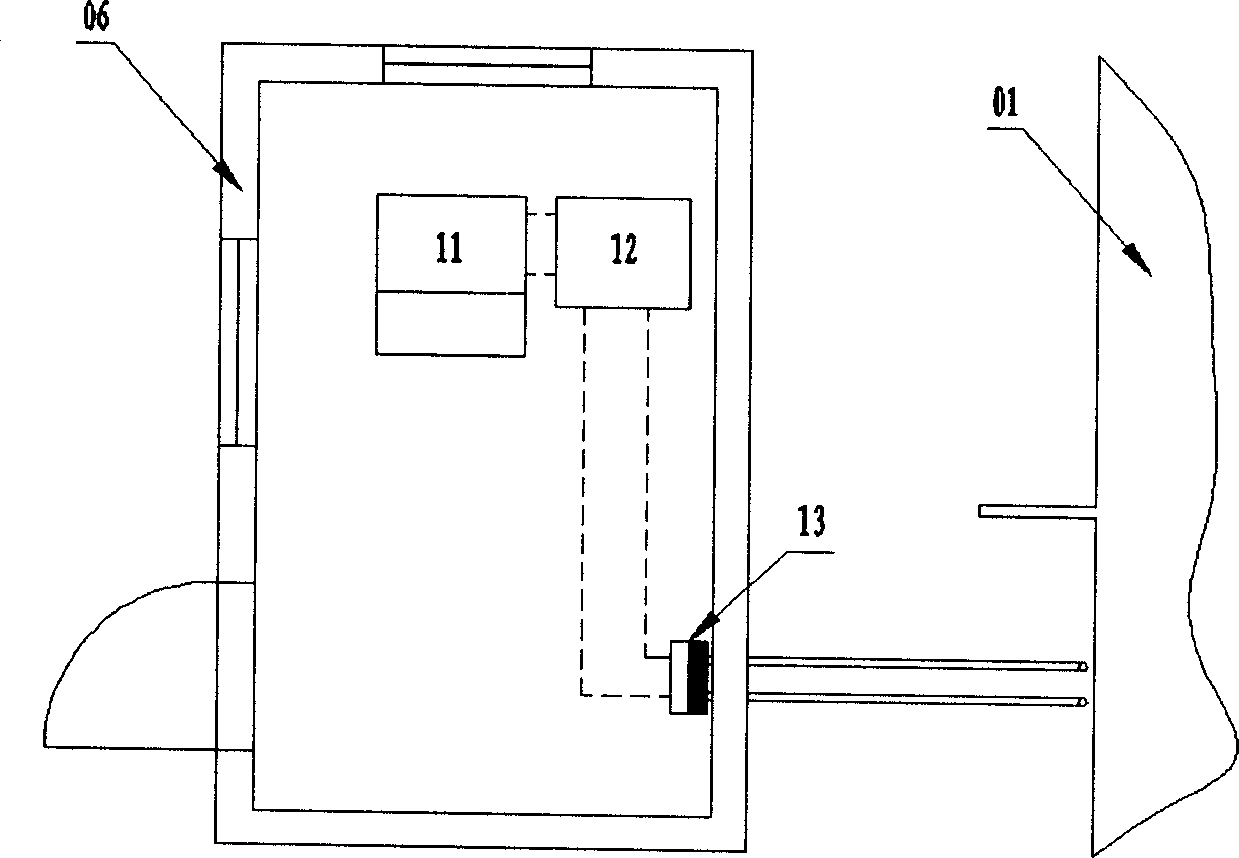

[0028] Such as figure 2 As shown, a console 11 and a control cabinet 12 are installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com