Retroreflection sheet and outer illumination type illumination system

一种逆反射、薄片的技术,应用在反射式反射器、化学仪器和方法、仪器等方向,能够解决成本升高、无法满足市场的需求、光量减少等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

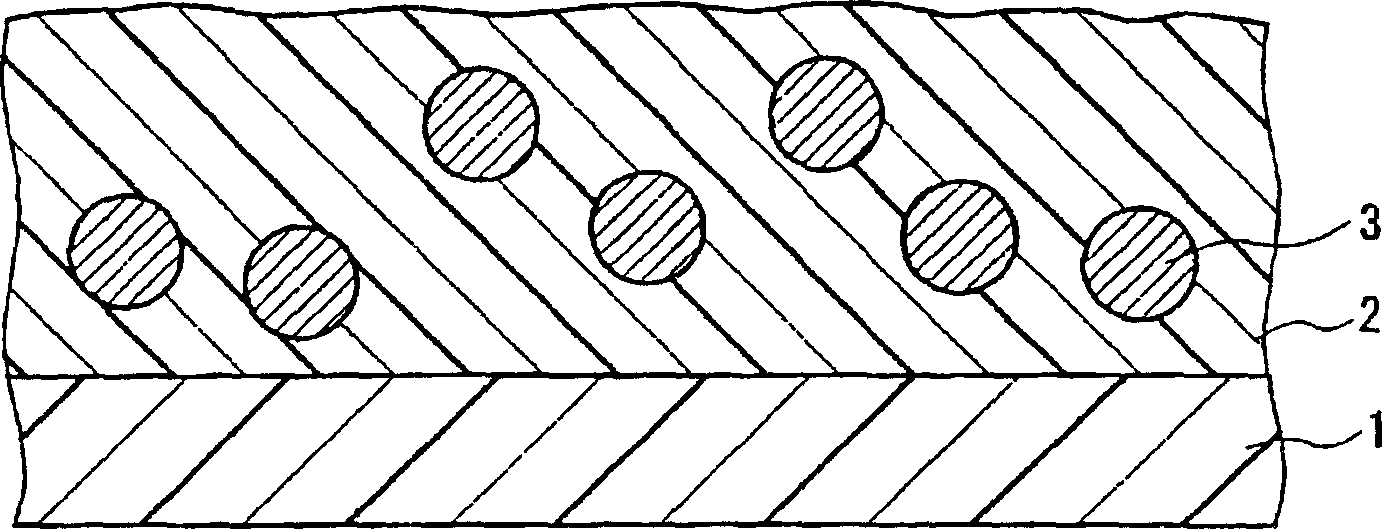

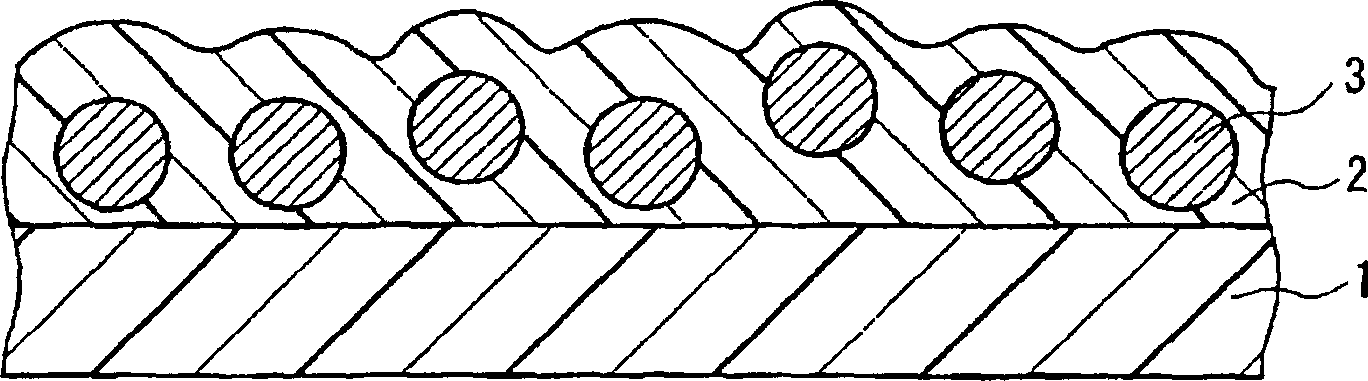

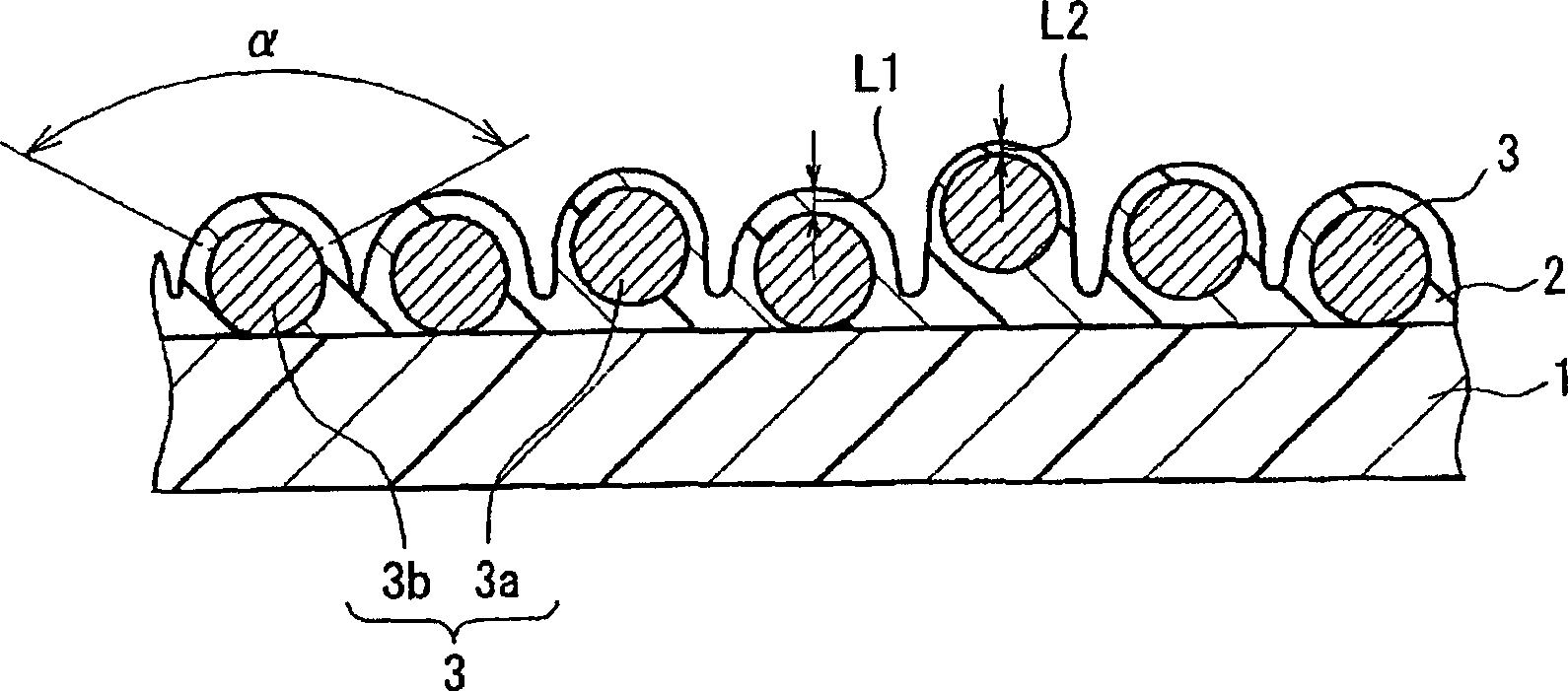

[0133] Shrinkage in the curl direction of the annealed biaxially oriented polyethylene terephthalate film used as the first surface layer (manufactured by Teijin DuPont Film, trade name MX534) at 150°C for 30 minutes Ratio of 0.3%, film thickness of 97 μm) was coated with the following glass sphere dispersion resin solution as a focus layer.

[0134] (1) Polyvinyl butyral resin solution: 75.0 parts (degree of polymerization: 680, polyvinyl alcohol unit 23% by weight, glass transition temperature 66°C, solid content 21%, n-butanol / toluene 1:1)

[0135] (2) Super Beckamine J-820-60: 3.3 parts (manufactured by Dainippon Ink Chemical Industry Co., Ltd., butylated melamine resin, solid content 60%)

[0136] (3) Beckamine P-198: 0.2 part (manufactured by Dainippon Ink Chemical Industry Co., Ltd., curing accelerator, acid value 400)

[0137] (4) BYK-053: 0.5 part (manufactured by BYK Chemie Japan, alkyl vinyl ether copolymer, antifoaming agent)

[0138] (5) Polysider W-360-ELS: 7.0...

Embodiment 2

[0150] Annealed biaxially oriented polyethylene terephthalate film (manufactured by TeijinDuPontFilm, trade name MX534, shrinkage in the curling direction of the film when heated at 150°C for 30 minutes, 0.3%, film thickness 97 μm) On, the following glass ball resin dispersion solution was coated.

[0151] (1) Polyvinyl butyral resin solution: 98.0 parts (polymerization degree: 1100, polyvinyl alcohol unit 18% by weight, glass transition temperature 76°C, solid content 16%, n-butanol / toluene 1:1)

[0152] (2) Beckamine P-196-M: 3.0 parts (manufactured by Dainippon Ink Chemical Industry Co., Ltd., butylated urea resin, solid content 60%)

[0153] (3) Beckamine P-198: 0.1 part (manufactured by Dainippon Ink Chemical Industry Co., Ltd., curing accelerator, acid value 400)

[0154] (4) BYK-053: 0.5 part (manufactured by BYK Chemie Japan, alkyl vinyl ether copolymer, antifoaming agent)

[0155] (5) PolysiderW-360-ELS: 2.0 parts (manufactured by Dainippon Ink Chemical Industry Co....

Embodiment 3

[0191] In the same manner as in Example 1, a glass bead-dispersed resin solution for a focus layer was produced. Next, in order to manufacture yellow, red, orange, green, and blue retroreflective sheeting, the following colorants were mixed with the aforementioned glass bead-dispersed resin solutions for focus layers of different colors.

[0192] (1) Focus layer glass sphere dispersion resin solution for yellow: 20% solution of toluene / n-butanol (1 / 1) of AWB-CP201 orange (manufactured by Nikko Bics: pigment concentration 40%) of 0.2 g, AWB of 3.5 g -Toluene / n-butanol (1 / 1) 20% solution of CP310 yellow (manufactured by Nikko Bics: pigment concentration 50%)

[0193] (2) Red focal layer glass sphere dispersion resin solution: 20% solution of toluene / n-butanol (1 / 1) of AWB-CP102 red (manufactured by Nikko Bics: pigment concentration 50%) of 5.5 g

[0194] (3) Focus layer glass sphere dispersion resin solution for orange: 20% solution of toluene / n-butanol (1 / 1) of 4.9 g of AWB-CP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com