Automatic cake production line flow process and technology

A production line, fully automatic technology, applied in the processing of dough, baking, baked food, etc., can solve the problems of sticky hands, difficult to control quality, unsanitary, etc., to solve the problem of loose and crispy, reduce production costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

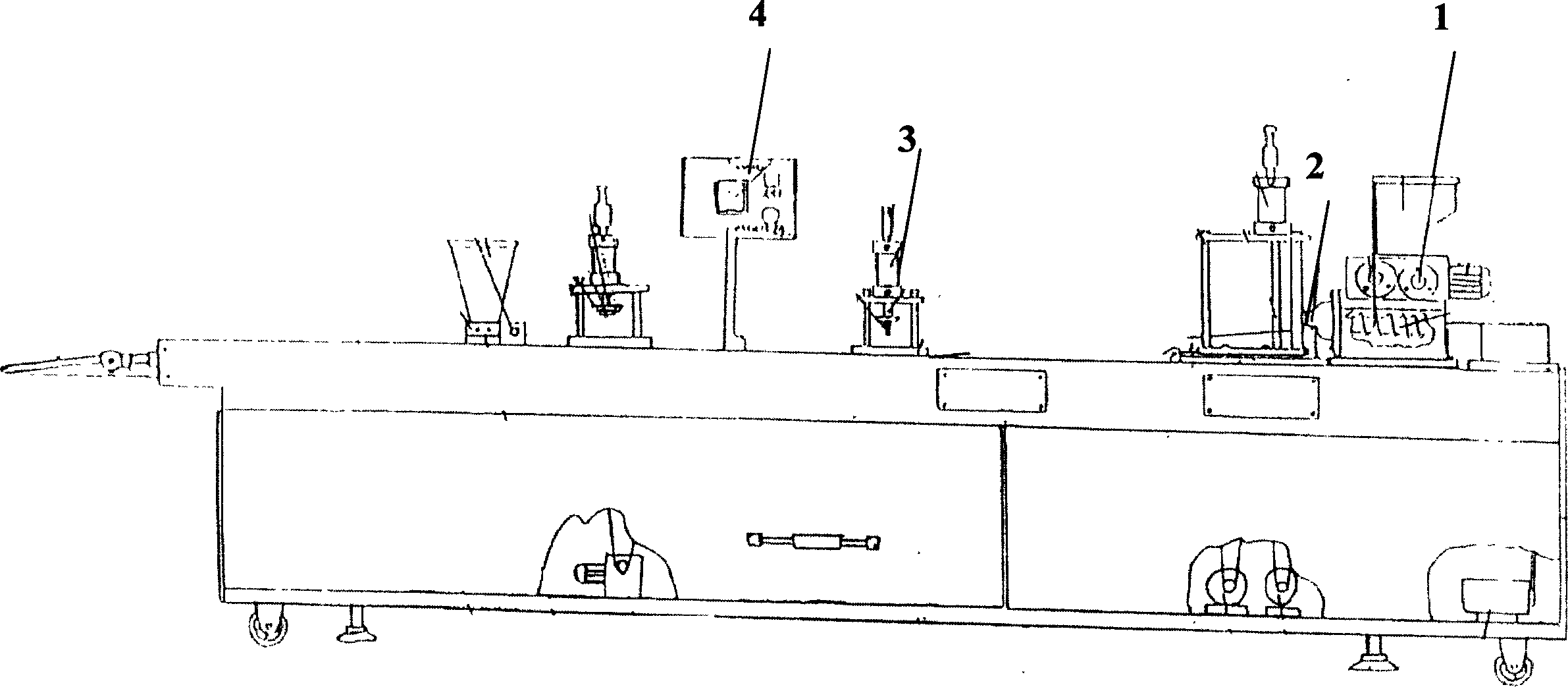

[0016] Refer to the accompanying drawings, the process flow from right to left is: after the raw and auxiliary materials are pretreated and mixed; in the discharge device 1, the raw materials are extruded by double-screw extrusion, and the cutting device 2 is cut by steel wire cutting. The computer 4 automatically controls the finishing, and after passing through, the mold forming device 3 adopts a forming non-stick mold, a Gateflon mold, controls the heating and demoulding at 35°C, and then bakes at 180°C for 18 minutes, finishing, and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com