Thawing stripping type ice making apparatus

A detachment and hot-melt technology, applied in ice making, ice making, lighting and heating equipment, etc., can solve the problems of uneven thickness of flake ice, large power consumption, slow ice making speed, etc., and achieve high utilization rate of evaporation area , prolong the service life and improve the ice storage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

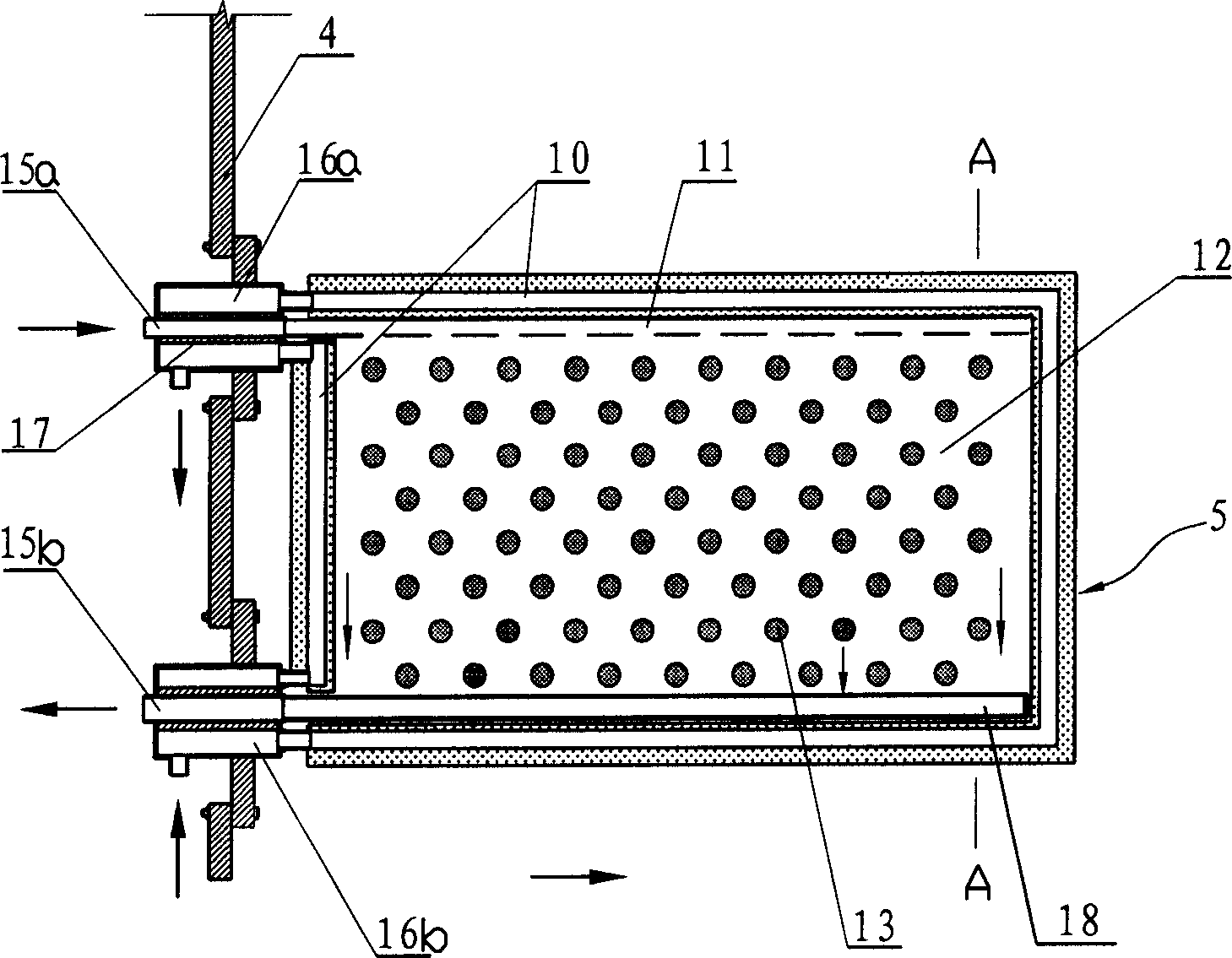

[0029] Example 2, such as Figure 5 and Figure 6 As shown, it differs from the above-mentioned first embodiment in that the evaporating plate is wound by a serpentine tube to form the refrigerant low-pressure liquid channel 12, and a circle of tubes is surrounded around the serpentine tube to form The thermal fluid channels 10 are connected to each other as a whole through metal fins 19 between adjacent tubes. Its working principle is the same as that of the above-mentioned first embodiment, and will not be described in detail here.

Embodiment 3

[0030] Example 3, such as Figure 7 As shown, it differs from the above-mentioned first embodiment in that the evaporating plate is wound by a serpentine tube to form the refrigerant low-pressure liquid channel 12, and the serpentine tube is surrounded by a circle and adjacent The pipes connected by the serpentine pipes form the thermal fluid channel 10, and the two sides of the serpentine pipes are respectively covered with metal sheets 20, and the cavity formed between each metal sheet and the serpentine pipes is filled with thermal fluid. Make the heat transfer effect better.

Embodiment 4

[0031] Example 4, such as Figure 8 As shown, it differs from the above-mentioned first embodiment in that: there is air in the hot fluid channel 10, and the air can be outdoor air or hot air, as long as its temperature is higher than the freezing temperature. In this way, driven by the blower fan 21 , the air continuously flows in the thermal fluid channel 10 , and the sensible heat of the air is used to separate the ice flakes on both sides. In this embodiment, the air can also be replaced by hot water or steam or antifreeze. At the same time, the refrigerant coming out of the filter drier 6 enters the low-pressure liquid receiver 8 after passing through the regenerator 22 and the thermal expansion valve 7. In this way, the heat exchange between the condensate and the suction air of the compressor is carried out through the regenerator 22 , thereby increasing the suction air temperature and working efficiency of the compressor 1 .

[0032] When the above-mentioned ice makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com