Technology and apparatus for detecting single-beam multi-wavelength mixed gas concentration in mine shaft

A mixed gas and concentration detection technology, used in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of complexity, hidden dangers, application limitations of gas detection instruments, etc., and achieve the effect of real measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with drawings and embodiments.

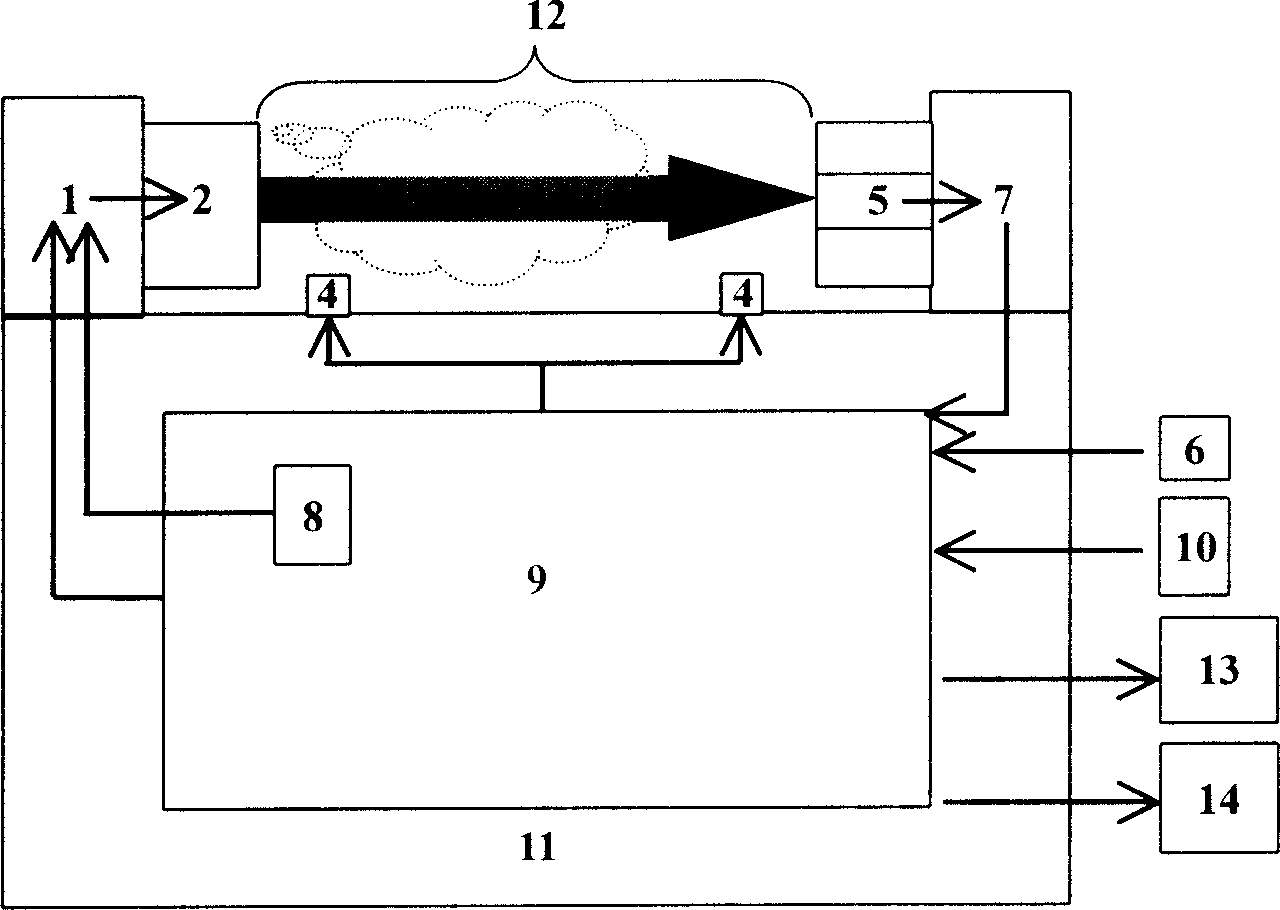

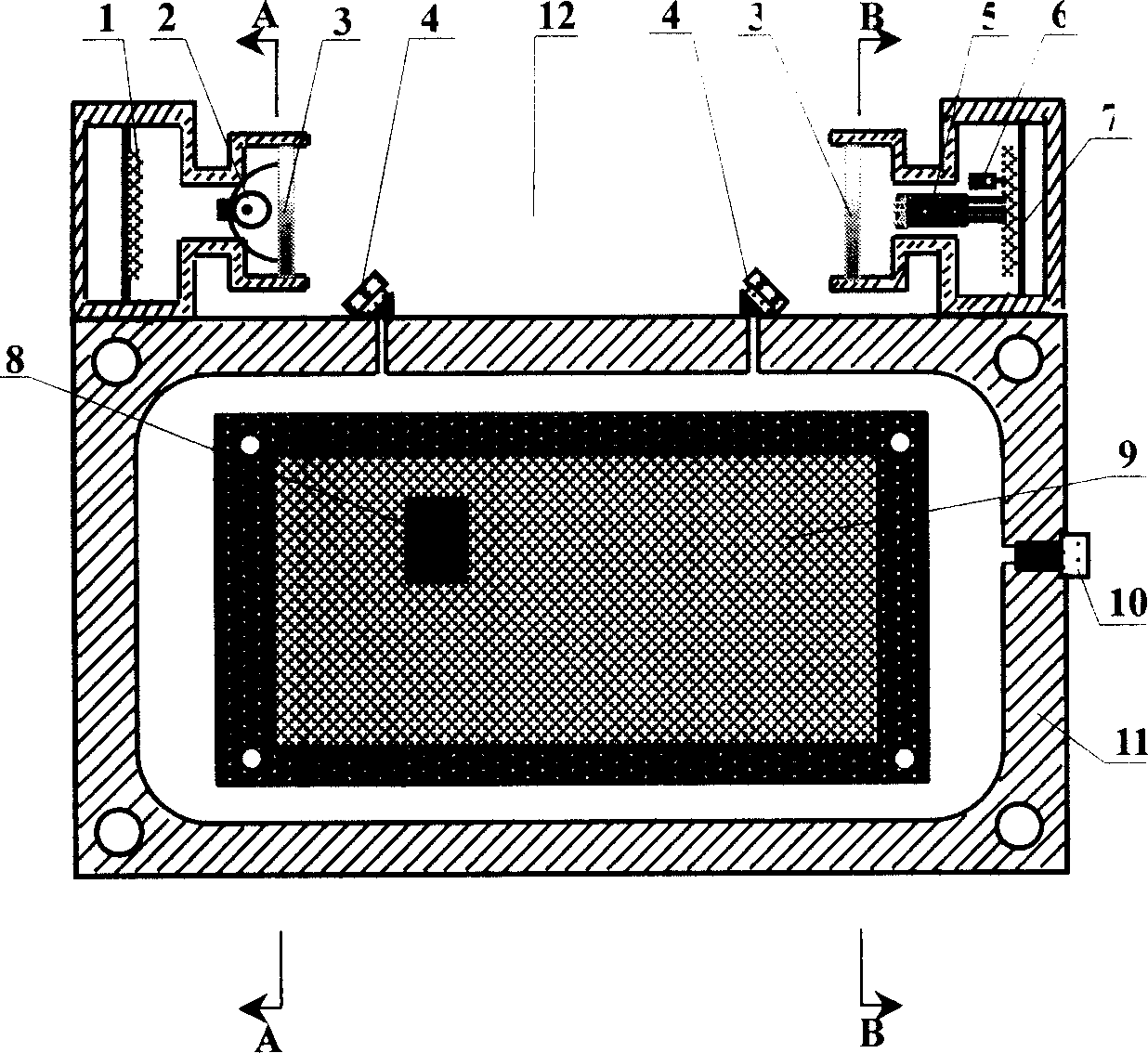

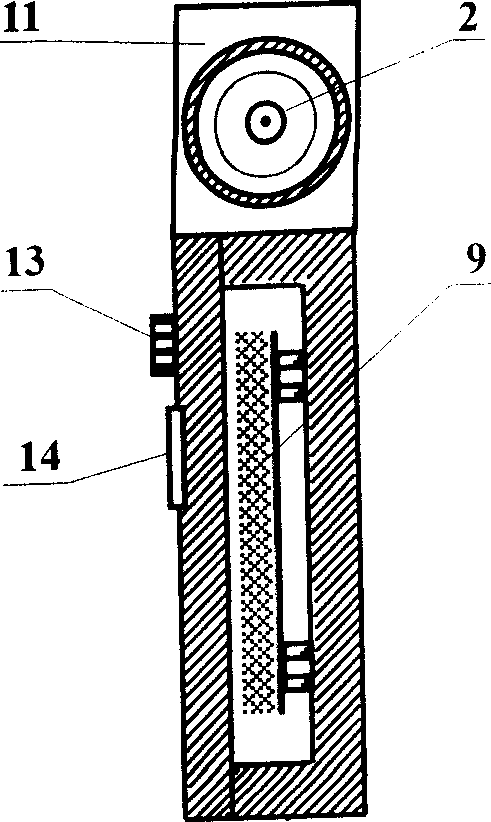

[0040] exist figure 1 , 2 , 3, 4 The meanings represented by the serial numbers: 1 light source power supply circuit 2 detection light source 3 transparent parts 4 oblique miniature electric fan 5 infrared detector group 6 temperature sensor 7 electric signal amplification circuit 8 modulation signal module 9 data acquisition and processing circuit 10 Oxygen concentration sensor 11 Housing 12 Open-cavity measuring gas chamber 13 Sound and light alarm system 14 Display modules 15, 16, 17, 18, 19 are filters of different wavelengths added to the receiving window of each detector.

[0041] The first embodiment is a single-beam multi-wavelength mixed gas concentration detection device in a mine. Its external dimensions are 200×145×40 mm, and it weighs about 0.7 kilograms. .

[0042] The device structure of this example can be found in figure 1 , 2 , 3, 4. One end on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com