Pearl-like decorative paper having suitability for postforming and thermosetting resin decorative sheet

A technology of forming processing and suitability, which is applied in the direction of synthetic resin layered products, decorative arts, paper/cardboard layered products, etc., can solve the problems of poor suitability for post-forming processing, no foaming, and difficulty in productization, etc., to achieve Avoid low quality, inhibit foaming or cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

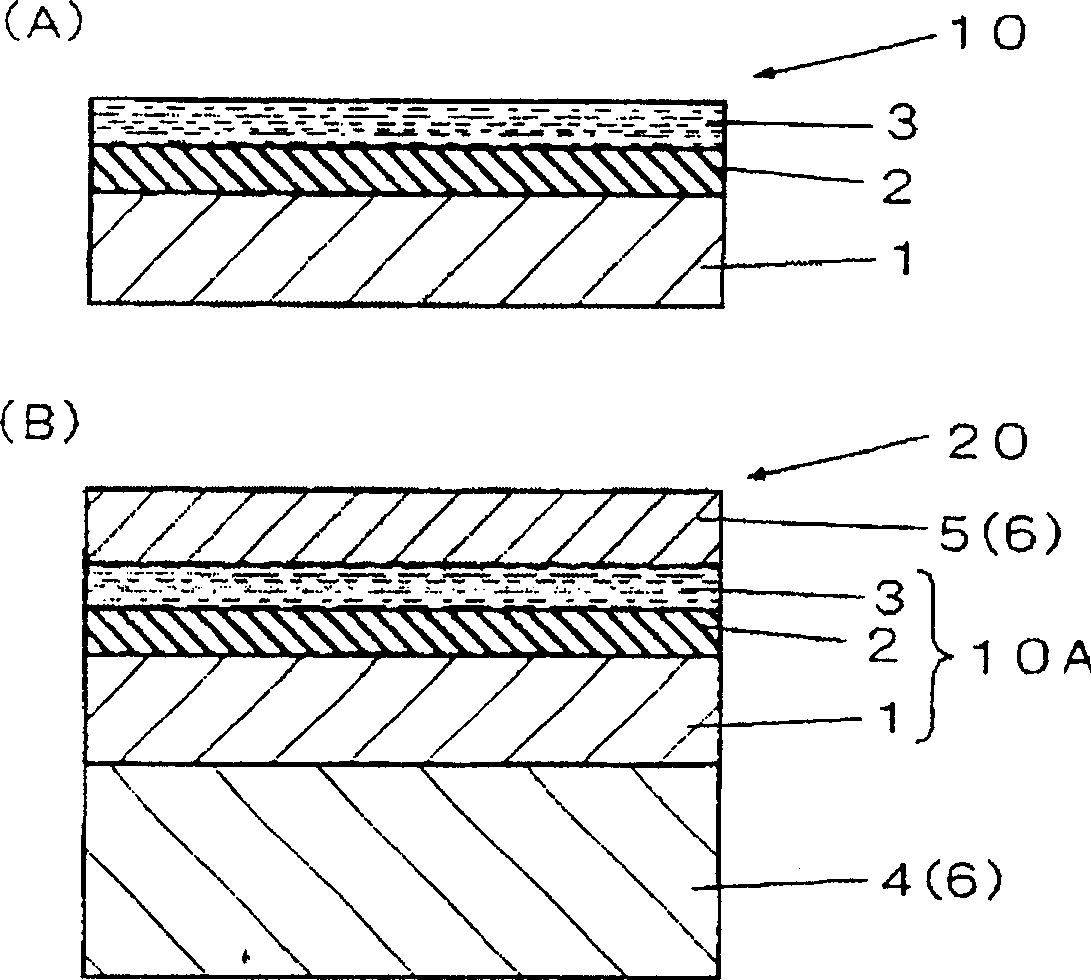

[0072] Such as figure 1 As shown in the cross-sectional views of (A) and (B), a pearlescent decorative paper 10 and a thermosetting resin decorative plate 20 suitable for post-forming processing are produced. First, as a paper base material 1 containing 20% by mass of titanium oxide and having a weight per unit area of 80 g / m 2 The pattern ink layer 2 and the pearl ink layer 3 using the pearl pigment described below were sequentially formed on the titanium paper using a gravure printing machine to produce the desired pearl luster decorative paper 10 .

[0073] The pattern ink layer 2 is formed by two-color printing, that is, a solid pattern using quinacridone as a colorant and a solid pattern using isoindolinone as a colorant. formed by layers. For the pearlescent pigment of the above-mentioned pearlescent ink layer 3, the pearlescent pigment WII grade or W-NT manufactured by Merck Co., Ltd., in which the scale-shaped foil of mica was covered with titanium dioxide, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com