Exposed wall thermal insulated decorative face brick, and its production method

A technology for external wall insulation and facing bricks, applied in construction, building structure, covering/lining, etc., can solve the problems of difficult quality assurance, manual work with high labor intensity and low strength, and meet the requirements of energy saving and environmental protection, and improve land quality. Utilization rate, effect of saving building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

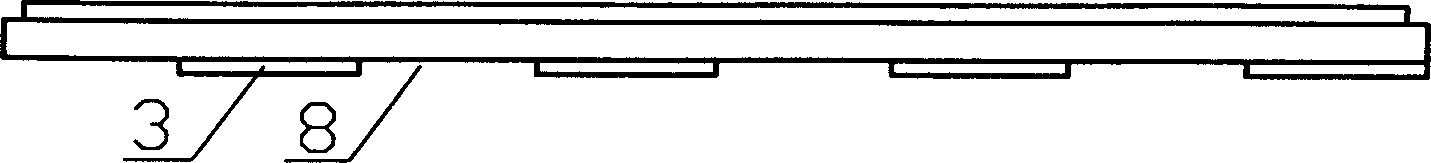

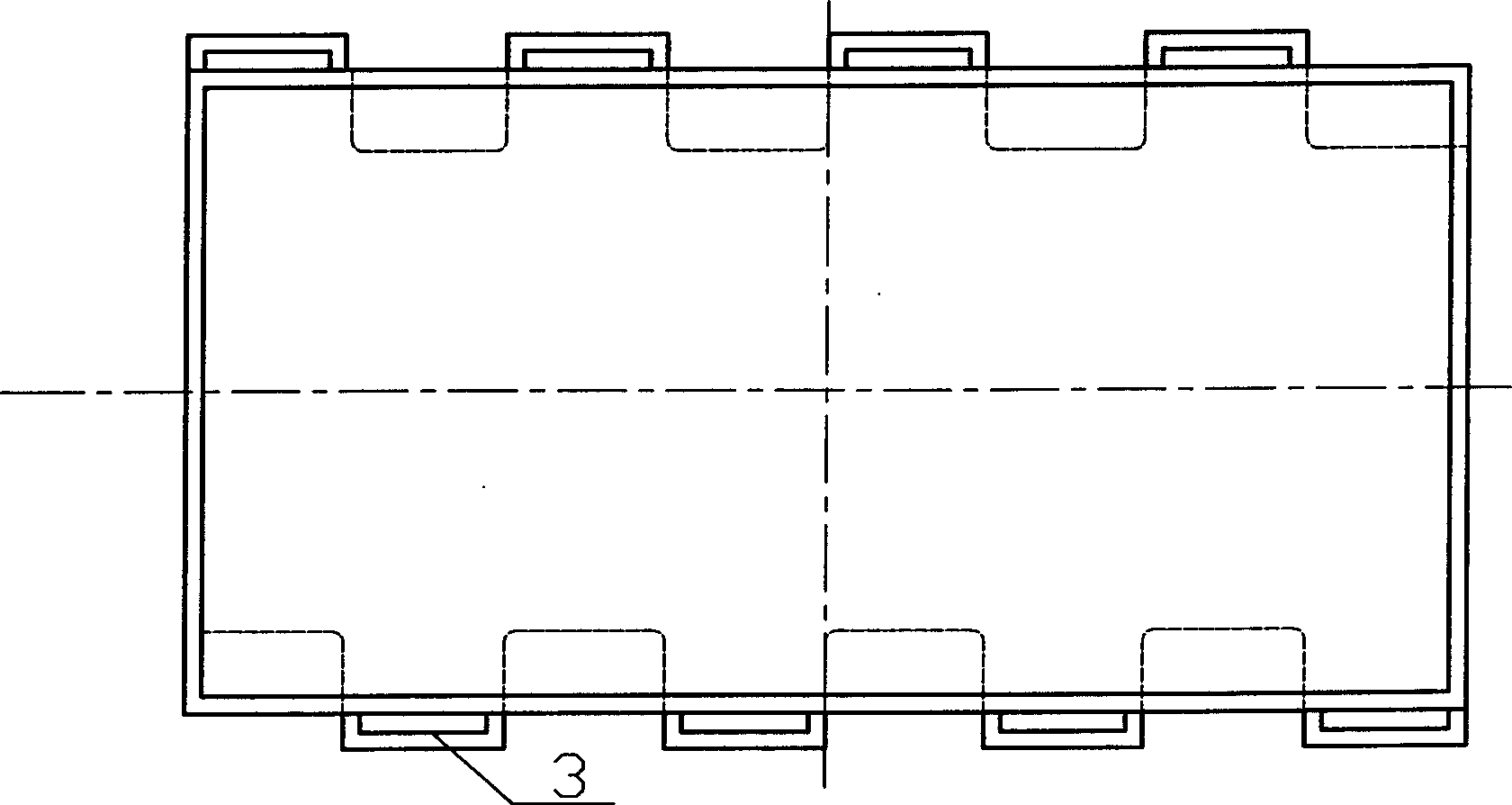

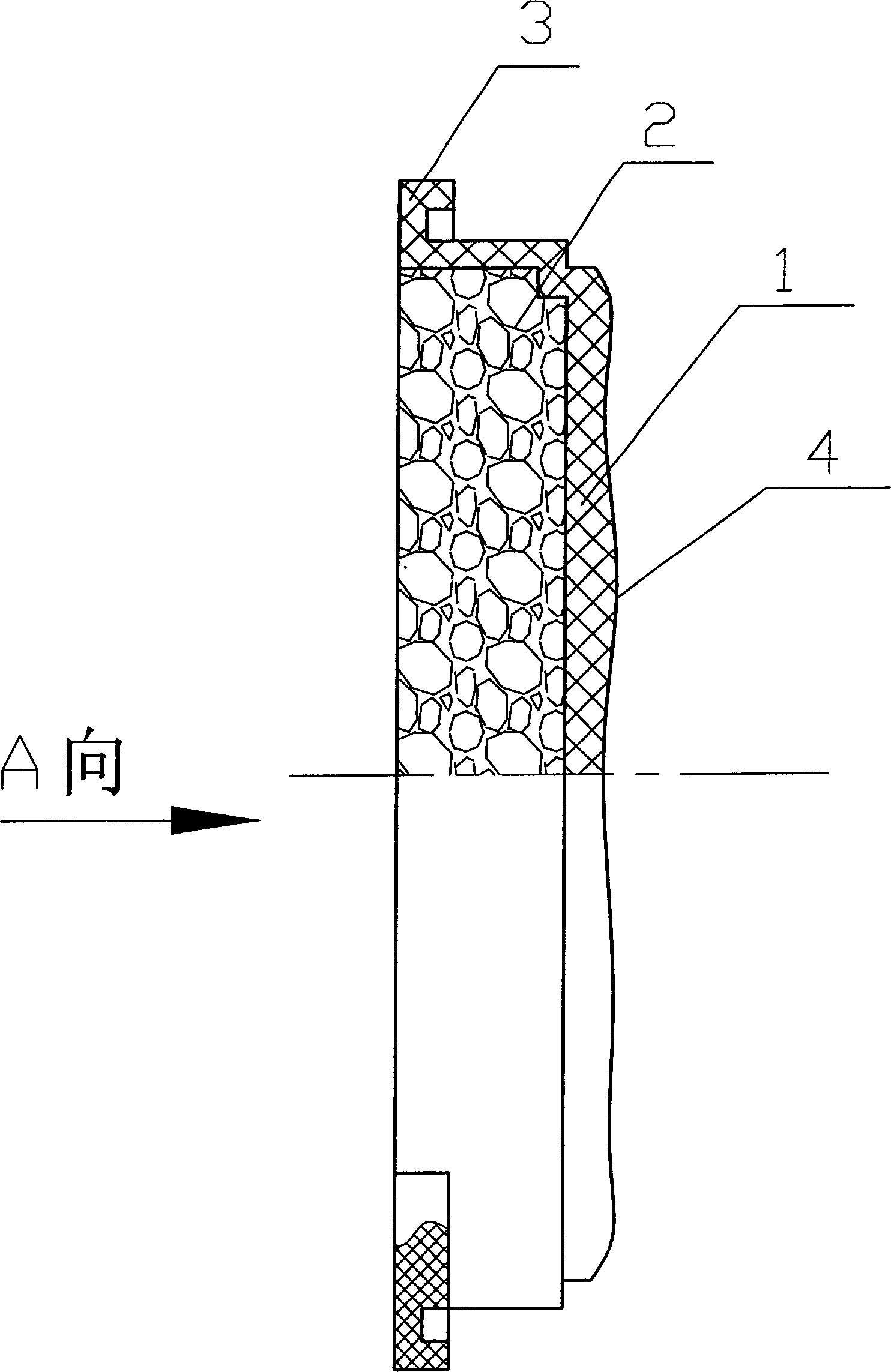

[0016] First is to make the mold used to produce the outer wall insulation and decorative brick shell shell of the present invention. According to the requirements of market customers, real materials such as marble or ceramic tiles can be selected, and the real texture of wood can be copied to make metal injection molds and be installed in injection molding. On the machine, adopt anti-oxidation macromolecule material, such as plastic-steel window material (modified PVC) according to the requirement deployment color after the rectangular box-type outer shell shell 1 of the external wall heat-preservation decorative face brick of injection molding, and the opening of the box body 1 The U-shaped protrusion 3 and the groove 8 protruding from the two sides of one side can have 8 protrusions and 8 grooves, and the thickness of the outer shell is 2 millimeters. Put the outer casing in the foaming mold and inject polyurethane foaming raw material, take it out after filling and curing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com