Split air conditioner with aluminium-made refrigeration pipeline

An air conditioner and split-type technology, which is applied in the field of improvement of split-type air conditioners, can solve problems affecting the safety of air conditioners, galvanic corrosion, etc., and achieve the effects of weight reduction, high safety, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

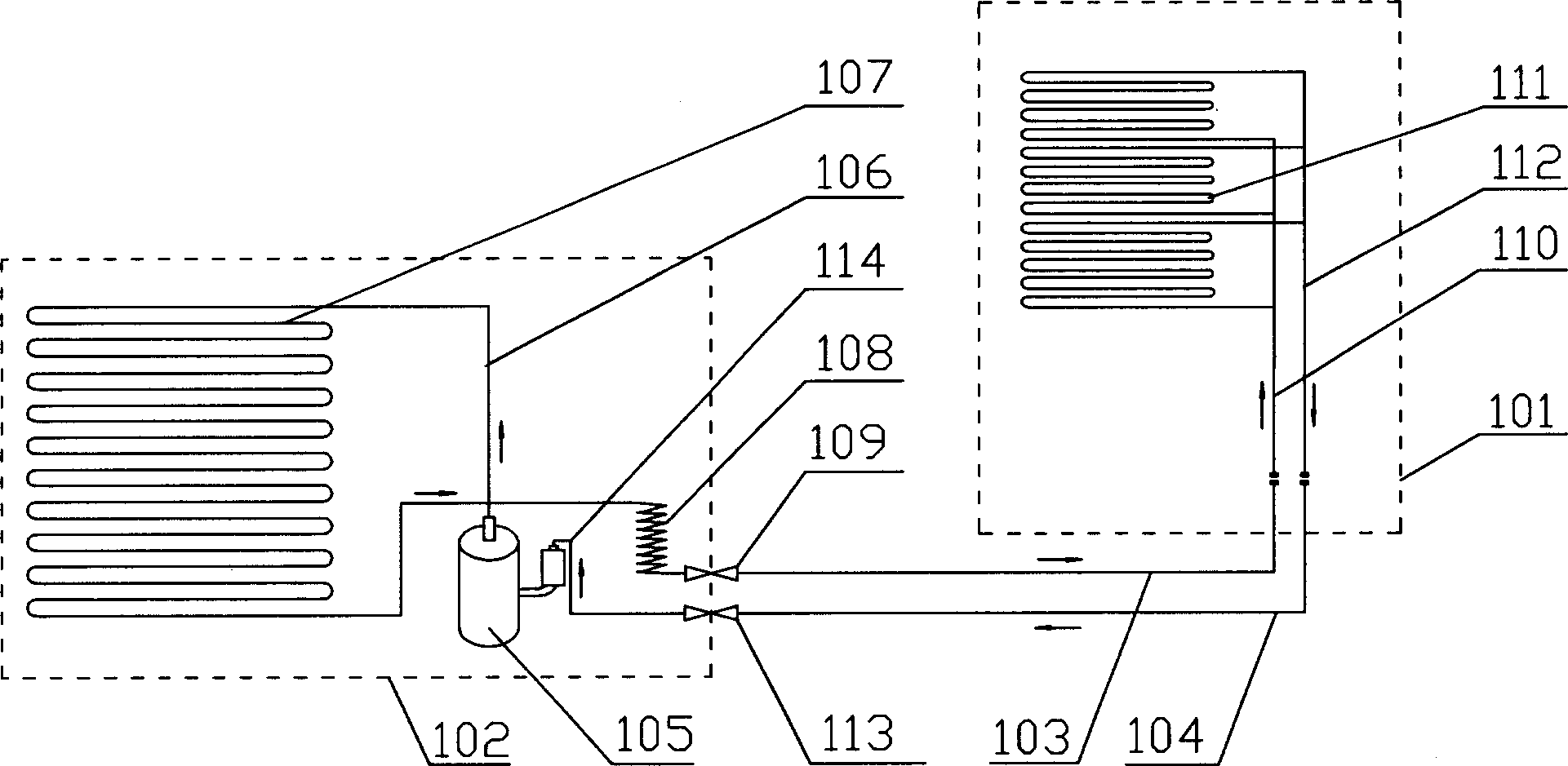

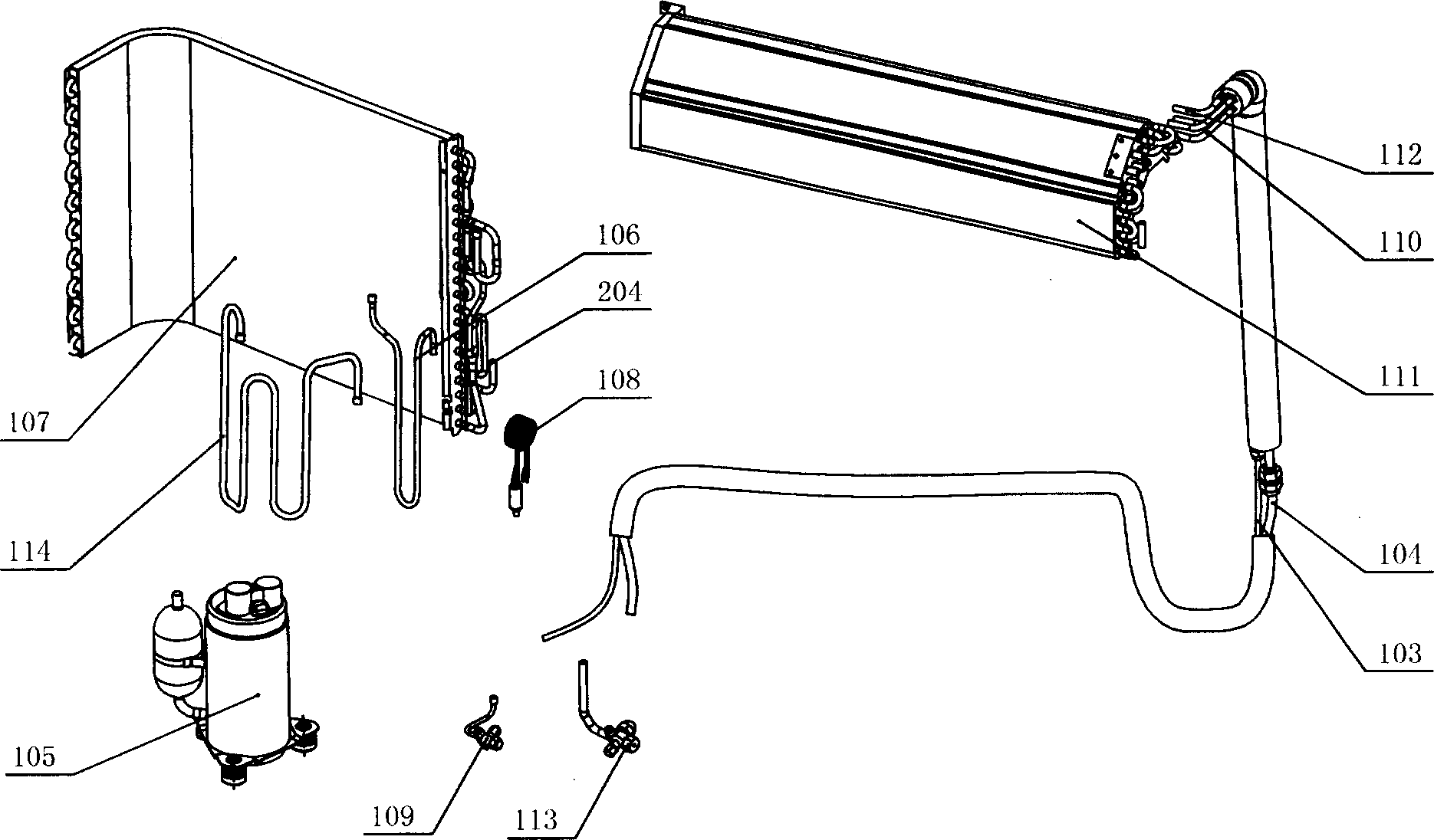

[0019] as attached figure 1 Shown is the pipeline flow diagram of the refrigeration system of the split air conditioner. The split-type air conditioner is composed of an indoor unit 101, an outdoor unit 102, a connecting pipe A 103 connecting the indoor and outdoor units, and a connecting pipe B 104. Its refrigeration system includes a sequentially connected compressor 105, exhaust auxiliary pipeline 106, and condenser 107. , capillary assembly 108, shut-off valve A 109, indoor and outdoor connecting pipe A 103, indoor unit auxiliary pipeline A 110, evaporator 111, indoor unit auxiliary pipeline B 112, indoor and outdoor connecting pipe B 104, shut-off valve B 113, return Gas auxiliary pipeline 114. The compressor 105, exhaust auxiliary pipeline 106, condenser 107, capillary assembly 108, stop valve A 109, stop valve B 113 and return air auxiliary pipeline 114 are installed in the outdoor unit 102, and the indoor unit auxiliary pipeline A 110 , the evaporator 111 and the ind...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap