Dressed slow-releasing fertilizer and its production

A slow-release fertilizer and coating technology, which is applied in the field of coated slow-release fertilizer and its preparation, can solve the problems of insufficient slow-release performance, short dissolution time in the whole process, low dissolution rate, etc., so as to reduce the amount of coating and reduce fertilizer Dissolution rate, effect of reducing film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

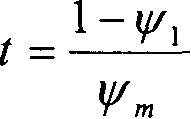

Method used

Image

Examples

preparation example Construction

[0042] In the preparation method of the film-coated slow-release fertilizer of the present invention, the adhesive composition used when coating the film can be an adhesive, or an adhesive precursor, or an adhesive or an adhesive precursor Compounds with barrier inorganic fillers, which can also be mixed with adjustment aids, solvents or dispersion media, etc. When coating to form a film, the adhesive composition should be made into a liquid form (such as by heating) so as to be coated and formed into a film. The impermeable inorganic filler can be coated once on the surface of the granular fertilizer after coating the liquid binder composition for several times. In order to implement multiple coatings smoothly, the adhesive composition of the inner layer can be properly cured during the coating process or between two coatings, but it should be ensured that there is a sticky coating on the surface of the granular fertilizer when the barrier inorganic filler is adhered. layer ...

Embodiment 1

[0059] Using unsaturated polyester resin as binder, nano CaCO 3 (The average particle diameter is 80nm, the same below) is a barrier inorganic filler to prepare coated slow-release urea. Nano-CaCO 3 Surface treatment with surfactants to prepare nano-active CaCO 3 use.

[0060] Mix the unsaturated polyester resin prepolymer (brand A400-972, produced by Nanjing Jinling DSM Co., Ltd., the same below), the initiator dibenzoyl peroxide and the catalyst dimethylaniline, and make a binder combination and defoaming for later use. In the adhesive composition, the mass dosages of dibenzoyl peroxide and dimethylaniline are respectively 1.5% and 0.8% of the unsaturated polyester resin prepolymer.

[0061] Add the granular urea into the fluidized bed coating equipment, and keep the granular urea in a boiling state, so that the temperature of the granular urea in the fluidized bed is kept at 70°C. The adhesive composition is continuously sprayed on the surface of urea, and at the same ...

Embodiment 2

[0063] Using unsaturated polyester resin as binder, nano CaCO 3 As a barrier inorganic filler, a coated slow-release urea was prepared. Nano-CaCO 3 Surface treatment with surfactants to prepare nano-active CaCO 3 use.

[0064] Unsaturated polyester resin prepolymer, initiator dibenzoyl peroxide, catalyst dimethylaniline and nano-active CaCO 3 Mix evenly, prepare the adhesive composition and defoam for use. In the adhesive composition, the mass consumption of dibenzoyl peroxide and dimethylaniline is respectively 1.5% and 0.8% of the unsaturated polyester resin prepolymer, unsaturated polyester resin prepolymer: nanometer CaCO 3 The mass ratio is 95:5.

[0065] Add the granular urea into the drum coating equipment with a temperature control of 70°C, and rotate the drum (rotating speed: 50r / min) to make the granular urea flow in the drum. After evacuating until the residual pressure in the drum is about 10kPa, feed styrene gas into the drum coating machine until the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com